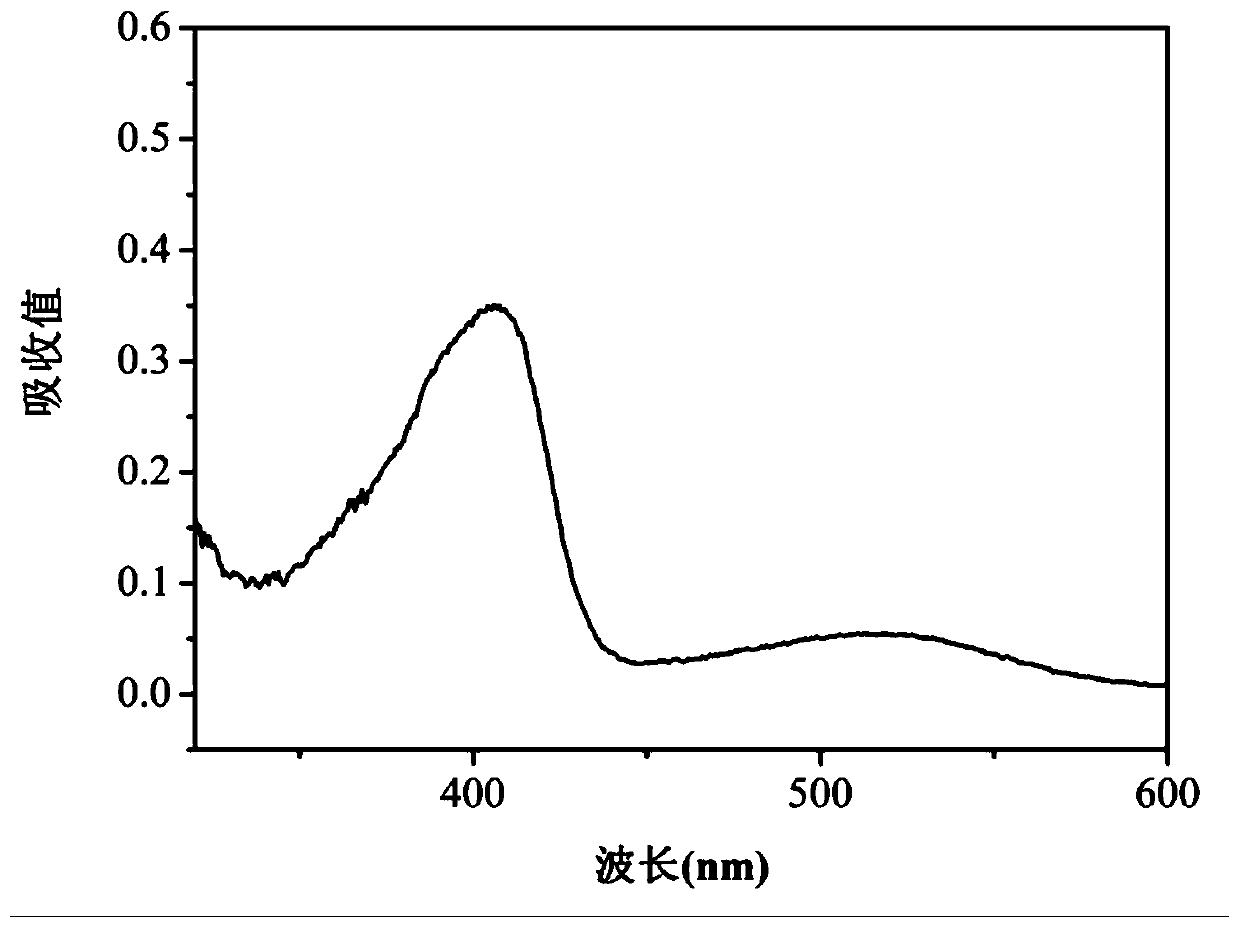

Thioxanthone derivative photo-initiator for UV-LED curing, preparation method and application thereof

A UV-LED and thioxanthone technology are applied in organic chemistry, coatings, epoxy resin coatings, etc., which can solve the problems of easy yellowing of cured film and restrict applications, so as to reduce yellowing, toxicity, and low Effect of yellowing and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

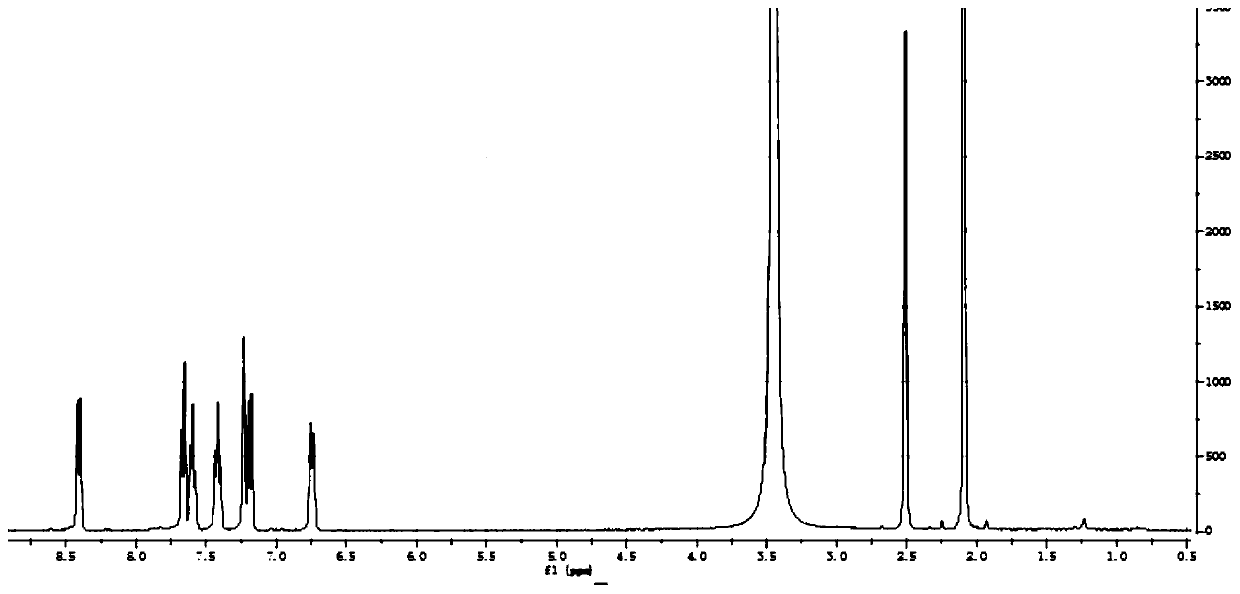

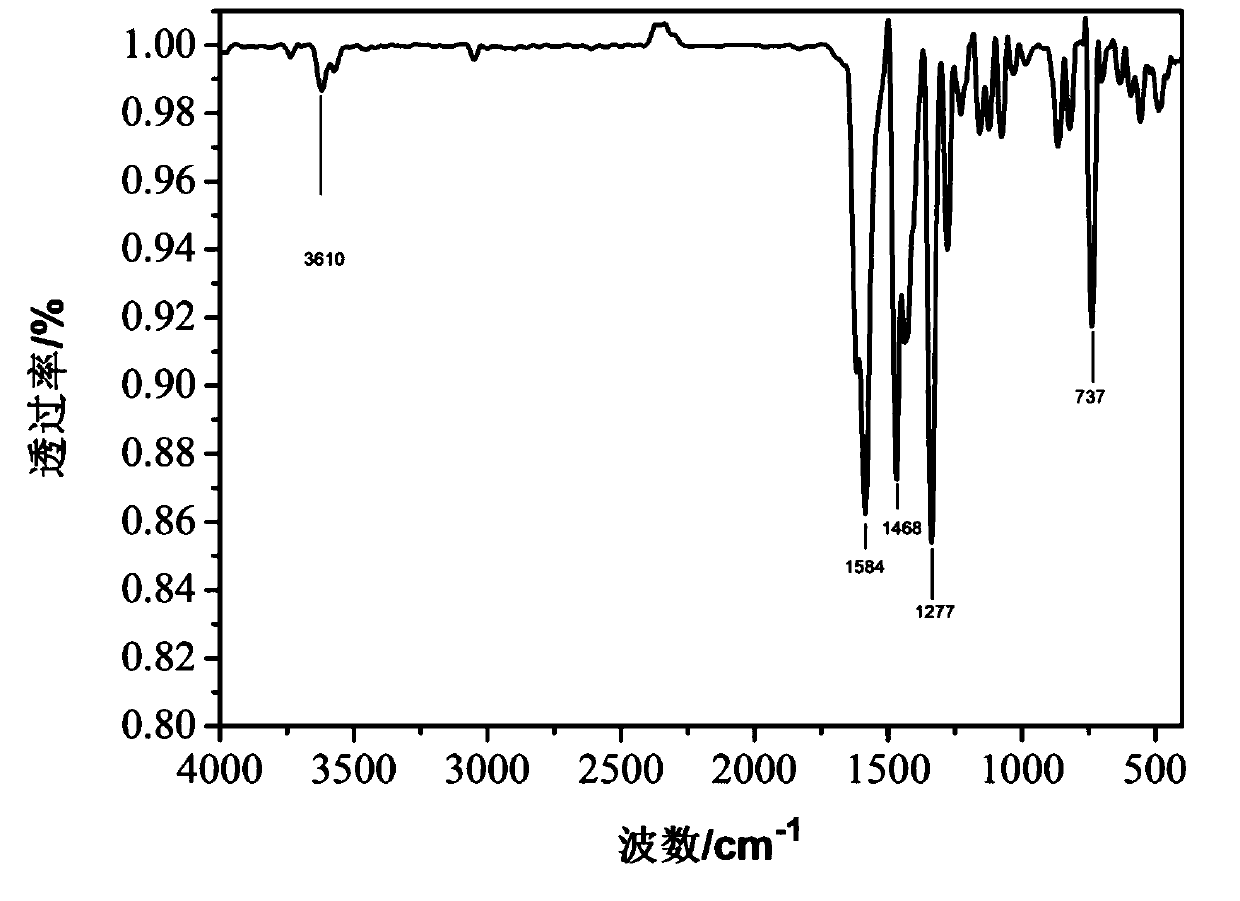

[0037] The reaction formula of a kind of thioxanthone derivative of the present embodiment:

[0038]

[0039](1) Condensation ring reaction: In a water bath environment at 0°C, after adding 15mL of concentrated sulfuric acid with a volume concentration of 98%, add 1.54g of thiosalicylic acid in batches under the stirring of the rotor stirrer, and wait until the solution is stirred and mixed evenly rear. Weigh 5.64g of phenol, drop it into the reactor for 20min, keep stirring at 0°C for 1h after the addition is complete. It was observed that the color of the solution became darker, so it was transferred to an oil bath environment at 70°C, and continued to stir for 5 hours of reaction. Let stand overnight. The solution in the reactor was poured into 50 ml of twice-distilled water at 0°C while stirring until precipitation appeared, stirred for 5 minutes, then filtered with suction, and washed with water several times to obtain a crude orange-red solid product.

[0040] (2) ...

Embodiment 2

[0053] (1) Condensation ring reaction: In a water bath environment at 5°C, after adding 20mL of 98% concentrated sulfuric acid, add 1.6g of thiosalicylic acid in batches under the stirring of the rotor stirrer, and wait until the solution is stirred and mixed evenly. Measure 3.36 g of p-cresol with an electronic analytical balance as quickly as possible, and add them to the reactor in batches, and keep stirring at 0°C for 2 hours after the addition is complete. It was observed that the color of the solution became darker, so it was transferred to an oil bath environment at 70°C, and continued to stir for 4 hours of reaction. Let stand overnight. Pour the solution in the reactor into 50ml of cold water at 0°C while stirring until precipitation occurs. After stirring for 10 minutes, filter with suction and wash with water several times to obtain a crude orange-red solid.

[0054] (2) After vacuum drying the crude product, weigh 28 g of sodium hydroxide solid, stir and add to 36...

Embodiment 3

[0062] (1) Condensation ring reaction: In a water bath environment at 2°C, after adding 18mL of 98% concentrated sulfuric acid, add 1.8g of thiosalicylic acid in batches under the stirring of the rotor stirrer, and wait until the solution is stirred and mixed evenly. Use an electronic analytical balance to measure 7.57g of catechol as quickly as possible, and add it to the reactor in batches, and keep stirring at 2°C for 1 hour after the addition is complete. It was observed that the color of the solution became darker, so it was transferred to an oil bath environment at 70°C, and continued to stir for 5.5 hours of reaction. Let stand overnight. The solution in the reactor was poured into 50ml of cold water at 2°C while stirring until precipitation appeared, stirred for 15 minutes, filtered with suction, and washed with water several times to obtain an orange-yellow crude product.

[0063] (2) After vacuum drying the crude product, weigh 30 g of sodium hydroxide solid, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com