Preparation method of pulverized coal rock optical sheet

A technology of pulverized coal and coal rock, which is applied in the field of preparation of pulverized coal rock light slices, can solve the problems that resin is easily trapped in air, difficult to separate, and difficult to discharge, so as to improve quality and utilization efficiency, high product quality, The effect of modeling convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

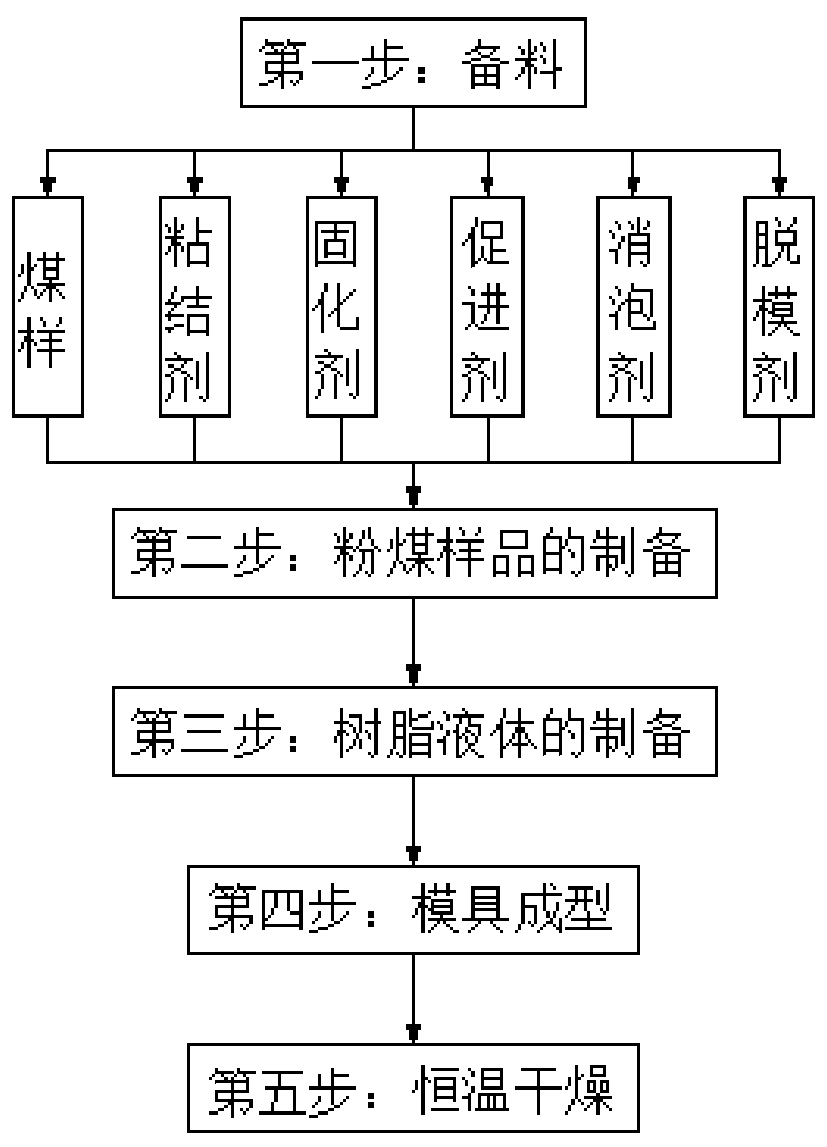

[0026] combine figure 1 shown.

[0027] Step 1: Preparation

[0028] Select coal, binder, curing agent, accelerator, defoamer and release agent as raw materials;

[0029] Step 2: Preparation of pulverized coal samples

[0030] First, the coal sample is pulverized with a pulverizer or a mortar, and then through repeated sieving and repeated crushing of the medium sample on the sieve until it completely passes through the test sieve, so that the weight of the coal sample smaller than 0.1mm does not exceed 10%. Weigh 100-200g of an air-dried coal sample with a particle size of less than 1mm, and divide it into 10-20g by stacking and quartering method for later use.

[0031] The third step: preparation of resin liquid

[0032] Unsaturated polyester resin, curing agent [cyclohexanone peroxide and dibutyl ester solution (1:1)], accelerator (6% solution of cobalt soap in styrene) and defoamer in proportion by weight, its The weight ratio is 100:4:4:2. The defoaming agent is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com