NCM ternary cathode material with recombinant La2nNi0.5Li0.5O4 and doped La<3+> on surface layer

A cathode material and surface layer technology, which is applied in the field of NCM ternary cathode materials, can solve the problems affecting the electrochemical cycle stability and safety performance of NCM ternary cathode materials, and the deterioration of electrode structure, so as to promote interlayer transport and inhibit increase. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

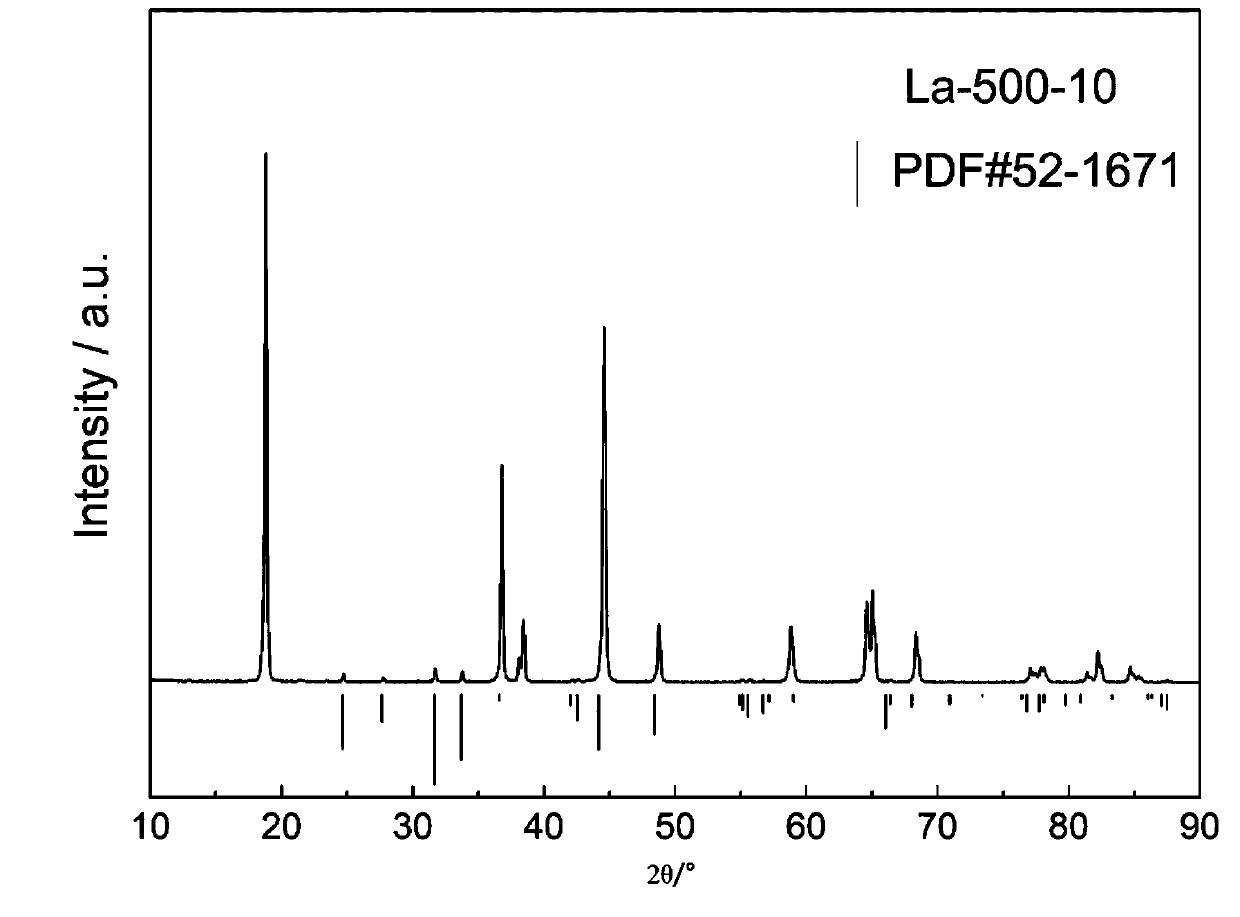

[0060] The LiNi synthesized in Comparative Example 1 0.869 co 0.921 mn 0.389 o 2 and La(NO 3 ) 3 ·6H 2 O crystal by LiNi 0.869 co 0.921 mn 0.389 o 2 : Mix La with a mass ratio of 0.99:0.01, sonicate in absolute ethanol for 1 h, then grind evenly in a mortar with absolute ethanol as a solvent, and finally calcinate at a high temperature of 500 ° C for 5 h to obtain a surface-recombined La 2 Ni 0.5 Li 0.5 o 4 and surface doped La 3+ The NCM ternary cathode material is denoted as La-500-10.

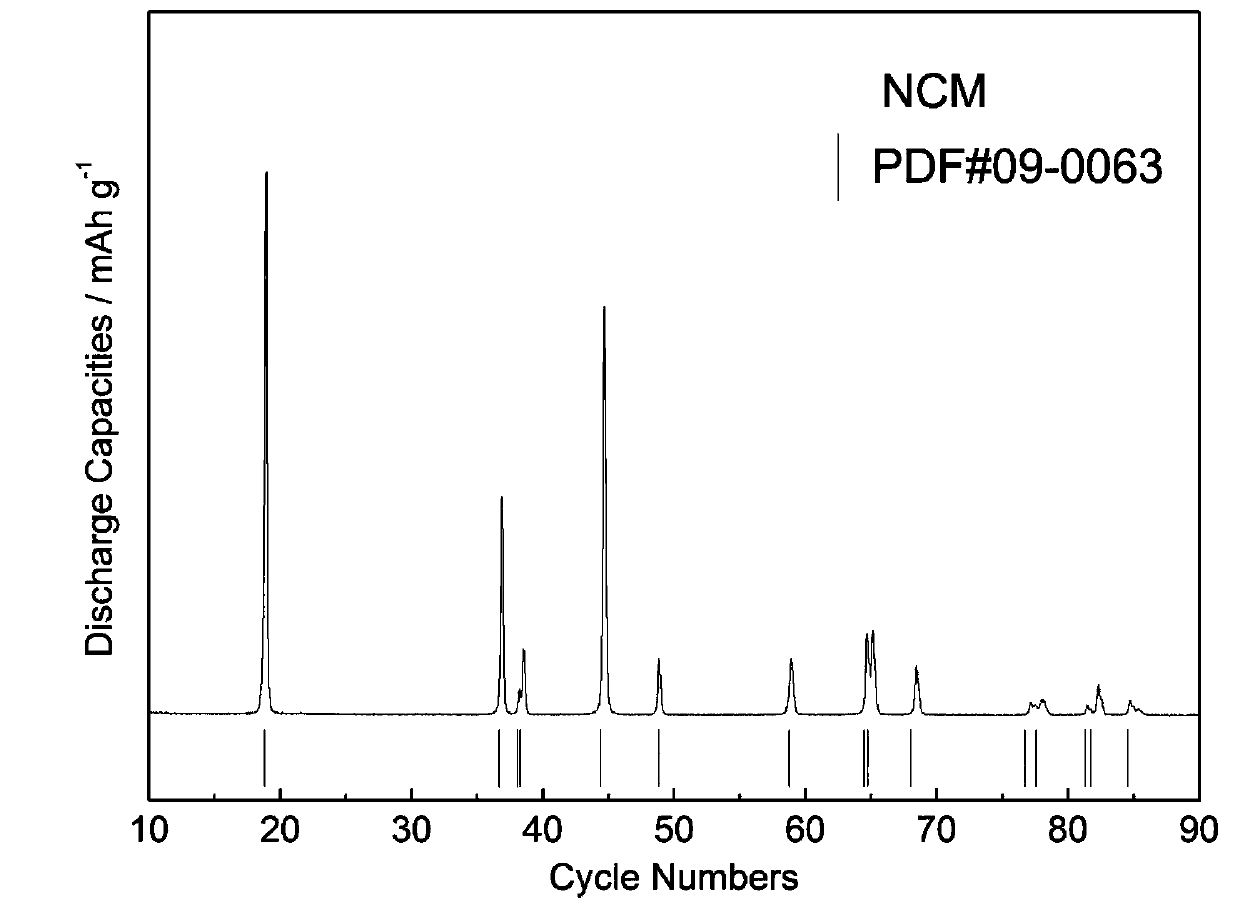

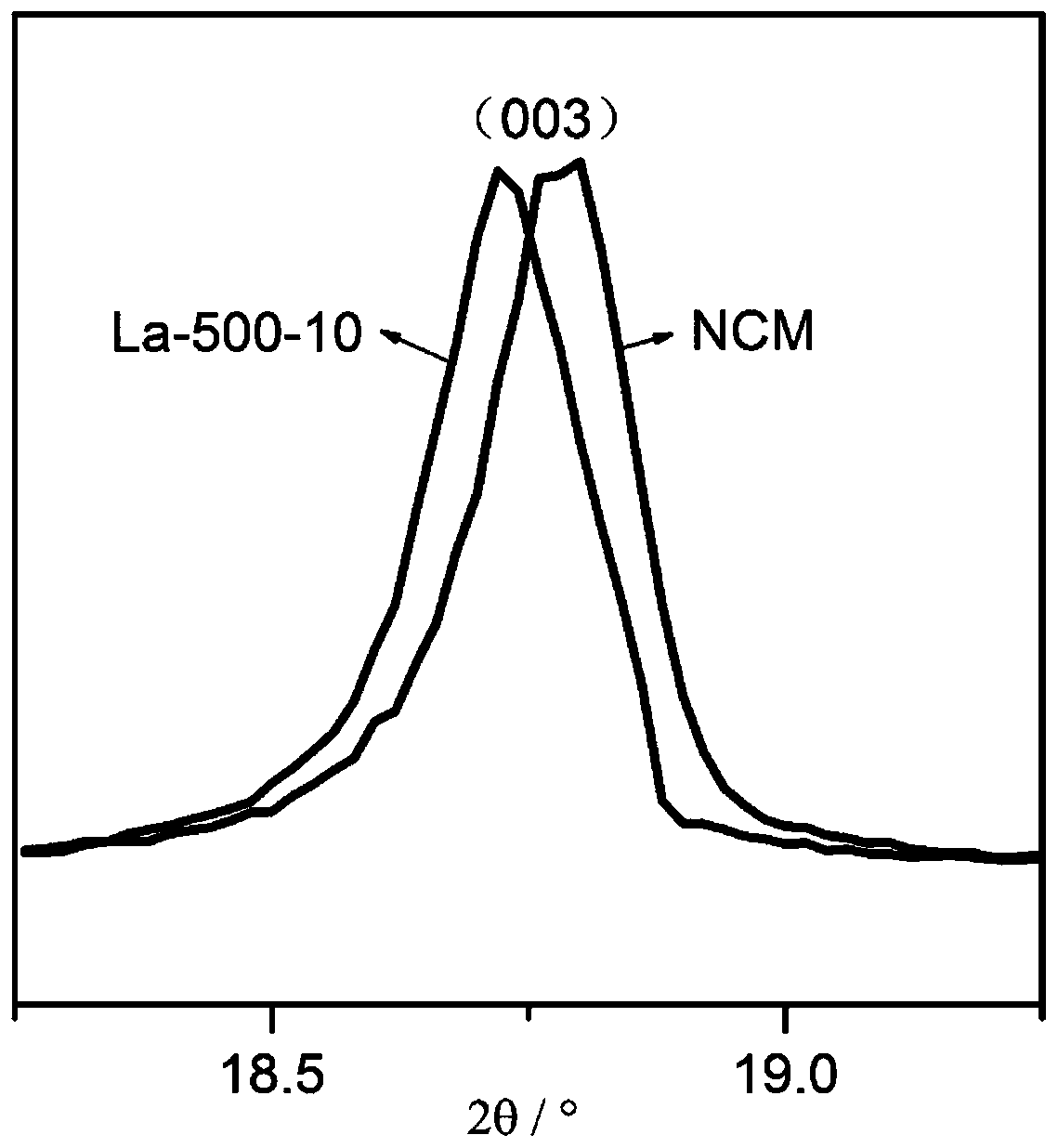

[0061] The XRD result of described material is as figure 2 As shown, it can be seen that the main peak of La-500-10 is also consistent with the position of the LiNiO2 peak, but there are several miscellaneous peaks between 20°-35°, and the miscellaneous peaks are consistent with PDF#53-1671, corresponding to La 4 NiLiO 8 , and the corresponding space group is I4 / mmm. Through XRD analysis, it is proved that there is a self-assembled cladding layer La on the surface layer. 2...

Embodiment 2

[0074] The LiNi synthesized in Comparative Example 1 0.869 co 0.921 mn 0.389 o 2 and La(NO 3 ) 3 ·6H 2 O crystal by LiNi 0.869 co 0.921 mn 0.389 o 2 : Mix La with a mass ratio of 0.99:0.01, sonicate in absolute ethanol for 1 h, then grind evenly in a mortar with absolute ethanol as a solvent, and then calcinate at a high temperature of 600 ° C for 5 h, a surface recombined La 2 Ni 0.5 Li 0.5 o 4 and surface doped La 3+ NCM ternary cathode material, denoted as La-600-10.

[0075] The 0.2C charge and discharge test results of the materials described in Comparative Example 1 and this example in the voltage range of 2.75 to 4.3V are as follows: Figure 6 As shown, it can be seen from the figure that the La-600-10 described in this example has a discharge capacity of 210.9mAh / g in the first week, a coulombic efficiency of 85.8% in the first week, and a discharge specific capacity of 200.7mAh / g after 50 cycles. 50 th The capacity retention rate was 95.2%. While the ...

Embodiment 3

[0077] The LiNi synthesized in Comparative Example 1 0.869 co 0.921 mn 0.389 o 2 and La(NO 3 ) 3 ·6H 2 O crystal by LiNi 0.869 co 0.921 mn 0.389 o 2 : Mix La with a mass ratio of 0.99:0.01, sonicate in absolute ethanol for 1 h, then grind evenly in a mortar with absolute ethanol as a solvent, and then calcinate at a high temperature of 750 ° C for 5 h to obtain a surface-recombined La 2 Ni 0.5 Li 0.5 o 4 and surface doped La 3+ NCM ternary cathode material, denoted as La-750-10.

[0078] The 0.2C charge and discharge test results of the materials described in Comparative Example 1 and this example in the voltage range of 2.75 to 4.3V are as follows: Figure 7 As shown, it can be seen from the figure that the La-750-10 described in this example has a discharge capacity of 205.8mAh / g in the first week, a coulombic efficiency of 86.2% in the first week, and a discharge specific capacity of 199.2mAh / g after 50 cycles. 50 th The capacity retention rate was 96.8%. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com