Preparation method of filled proton exchange membrane

A technology of proton exchange membrane and filling type, which is applied in the field of fuel cell cation exchange membrane preparation, can solve the problems of restricting large-scale development, fuel penetration, and reducing battery life, and achieve thermal stability and hydrolysis stability improvement, proton conductivity Improve the effect of novel membrane material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

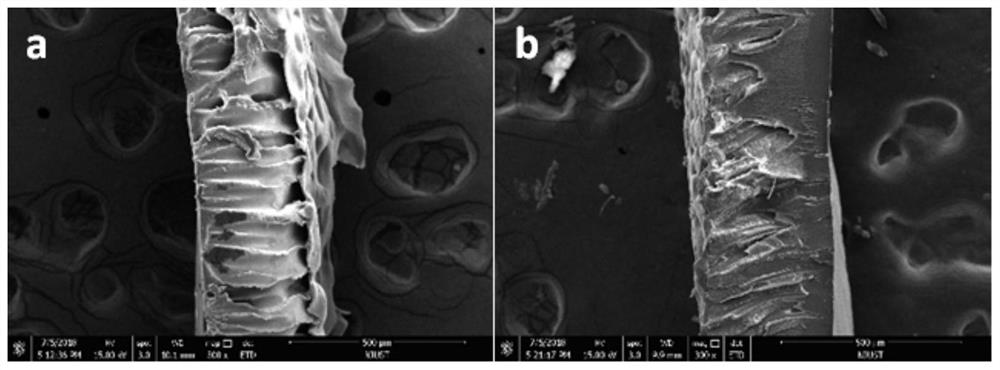

[0028] Example 1 Preparation of sulfonated polyarylethersulfone / polyethersulfone microporous membrane (S30-20)

[0029] At 60°C, add 4.9g of SPAES30 and 19.6g of PES dissolved in 75.5g of DMAc solvent into a dry round bottom flask, stir for 24h, and ultrasonically defoam to obtain a casting solution. Take a dry and clean glass plate, pour the solution evenly on it, and push it evenly and slowly with a glass rod to form a thin film. In an indoor environment with a humidity of about 40%, place it for 10 seconds, and then put the glass plate into deionized water. After the film is formed, rinse it repeatedly with deionized water to remove excess solvent. Soak the membrane in deionized water, isopropanol (IPA), and 1mol / L HCl for 24 hours respectively. When changing the solvent, wash off the original solvent on the membrane to obtain sulfonated polyarylethersulfone / polyether Sulfone microporous membrane, named S30-20.

Embodiment 2~6

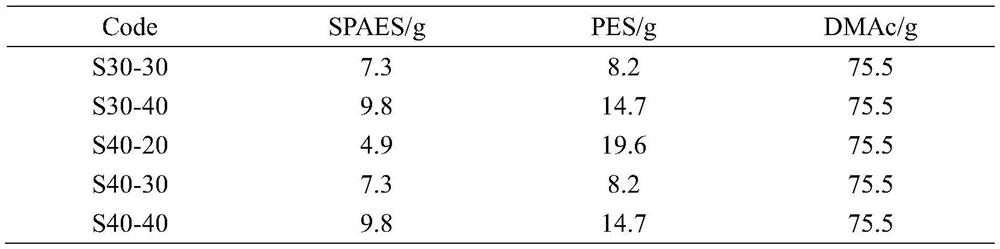

[0030] The preparation of embodiment 2~6 microporous membrane S30-30, S30-40, S40-20, S40-30 and S40-40

[0031] The preparation method of microporous membrane S30-30, S30-40, S40-20, S40-30, S40-40 is similar to that of microporous membrane S30-20, the difference is that L-SPAES with different sulfonation degrees and PES The blending ratios are different, and the specific feed ratios are listed in Table 1.

[0032] The specific feed ratio of table 1 microporous membrane

[0033]

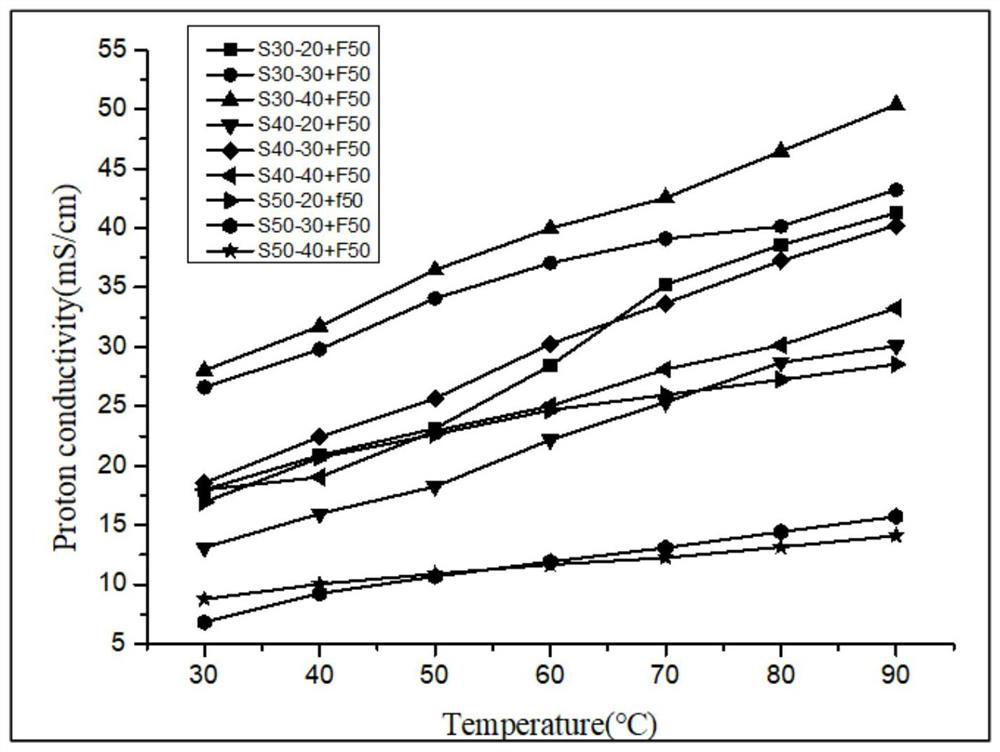

[0034] Table 2 lists the basic properties of S30-20, S30-30, S30-40, S40-20, S40-30, and S40-40. The actual IEC value of the film measured by acid-base titration is 0.21- 0.58mmol / g, the swelling rate at room temperature is 0.2%-2.15%, the water absorption rate increases from 64.1% to 122.8% at 30°C, and increases with the increase of temperature, under the premise of maintaining the dimensional stability of the film The water absorption rate is greatly improved, which is conducive to the stora...

Embodiment 7

[0035] The preparation of embodiment 7 filled film S30-20+F50

[0036] Dissolve SPAES50 in aqueous DMF (V DMF :V DI Water =3:2), the concentration was 5%, to obtain a polymer solution. Spread the S30-20 microporous membrane in a vacuum suction filtration device, infiltrate the polymer solution for a short time within 15s, dry and rinse, repeat three times, and dry the membrane in a vacuum oven at 45°C. The dried membrane was treated with hydrochloric acid, the pores were shrunk by isopropanol, rinsed repeatedly with deionized water, and dried naturally to obtain a filled proton exchange membrane named S30-20+F50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com