High-performance waterborne double-component polyurethane metal paint composition and application thereof

A two-component polyurethane and metal coating technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of inability to achieve rapid cross-linking, slow carbodiimide reaction, and shortened paint shelf life. Avoid storage risk problems, improve reactivity, and improve the effect of boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

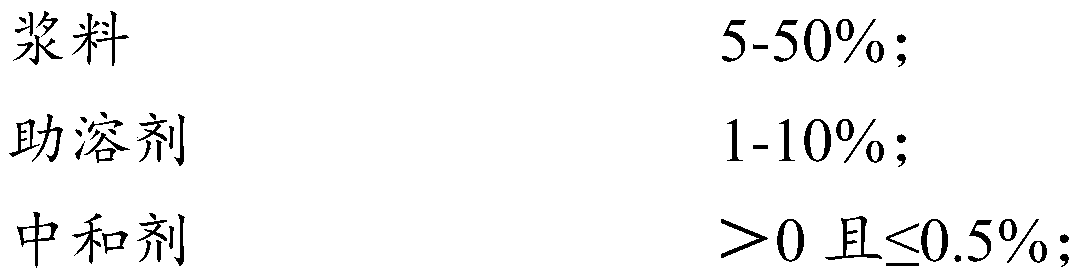

[0059] (1) The quality and raw material information of each component of the slurry of A component in the present embodiment are as follows:

[0060] raw material name

mass (g)

Grade

raw material supplier

water

20.0

/

/

Dispersant

3.5

BYK-190

BYK Company

Titanium dioxide

75.0

R-706

dupont

D

1.0

Surfynol 104BC

Evonik

0.5

Tego Airex904w

Evonik

[0061] The preparation of the slurry is carried out as follows: mix the water, dispersant, defoamer, and wetting agent in the above table and stir at a stirring speed of 200 rpm for 4 minutes, then add titanium dioxide and increase the stirring speed to Continue to stir at 1000 rpm for 15 minutes to obtain a uniformly mixed slurry; transfer it to a horizontal sand mill for 20 minutes to grind to a fineness of less than 10 microns, and filter through a 200-mesh gauze to obtain the slurry for later use.

[0062] (2) The ...

Embodiment 2

[0071] (1) The ratio of each component of the slurry of component A in this embodiment and the raw material information are as follows:

[0072]

[0073]

[0074] Its preparation method is as follows: mix the above-mentioned water, dispersant, defoamer, and wetting agent and stir at a stirring speed of 400 rpm for 3 minutes, then add pigments and fillers and increase the stirring speed to 1000 rpm to continue Stir for 10 minutes to obtain a uniformly mixed slurry; transfer it to a horizontal sand mill for 30 minutes to grind to a fineness of less than 10 microns, and filter through a 200-mesh gauze to obtain the slurry, which is set aside.

[0075] (2) The proportion and raw material information of component A are as follows:

[0076] raw material name

mass (g)

Grade

raw material supplier

Waterborne Hydroxy Acrylic Resin

65.0

Antkote2035

Wanhua Chemical Company

water

2.5

/

/

Neutralizer

0.1

N,N-Dimethylet...

Embodiment 3

[0083] (1) The ratio of each component of the slurry of component A in this embodiment and the raw material information are as follows:

[0084] raw material name

mass (g)

Grade

raw material supplier

water

20

/

/

Dispersant

3.8

BYK-190

BYK Company

Titanium dioxide

75.0

R-706

dupont

D

1.0

Surfynol 104BC

Evonik

0.5

Tego Airex904w

Evonik

[0085] Its preparation method is as follows: mix the above-mentioned water, dispersant, defoamer, and wetting agent and stir at a stirring speed of 400 rpm for 3 minutes, then add pigments and fillers and increase the stirring speed to 1000 rpm to continue Stir for 10 minutes to obtain a uniformly mixed slurry; transfer it to a horizontal sand mill and grind for 30 minutes to a fineness of less than 10 microns, and filter through a 200-mesh gauze to obtain the slurry, which is set aside.

[0086] (2) The proportion and raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com