Construction method of transverse joint and vertical joint of outer wall of prefabricated sandwich heat-preservation shear wall

A construction method and technology of transverse joints, applied to building insulation materials, building components, covering/lining, etc., can solve problems such as cracking and falling off of exterior wall coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

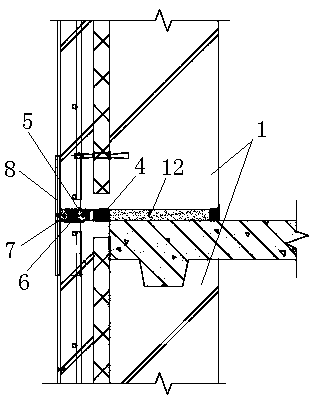

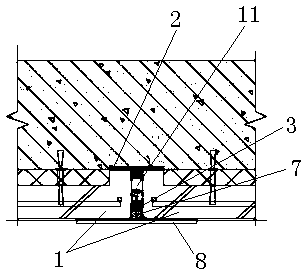

[0018] Example figure 1 and figure 2 As shown, the construction method of the transverse seam and the vertical seam of the outer wall of the prefabricated sandwich thermal insulation shear wall of the present invention comprises the following steps:

[0019] Step 1. Hoist the prefabricated concrete component 1 in place, and correct the level and verticality of the component to meet the design and specification requirements;

[0020] Step 2. Paste the self-adhesive rubber skin 2 on the inner side of the vertical joint 11 of the adjacent components and extend to both sides of the vertical joint 11 to prevent the concrete laitance and concrete from entering the vertical joint when pouring the concealed columns between adjacent components. In the seam 11, waterproof sealant 3 is applied on the outside of the rubber skin 2, so that adjacent components can be reliably connected to prevent leakage;

[0021] Step 3. After the components are installed, seal the grouting cavity from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com