Dry quenching furnace system with tail gas desulfurizing function and desulfurizing method thereof

A dry quenching furnace and functional technology, applied in the field of CDQ furnace system, can solve the problems of high cost, unfavorable production running, and great influence on field equipment space, and achieve the effect of reducing production cost and reducing the influence of equipment space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

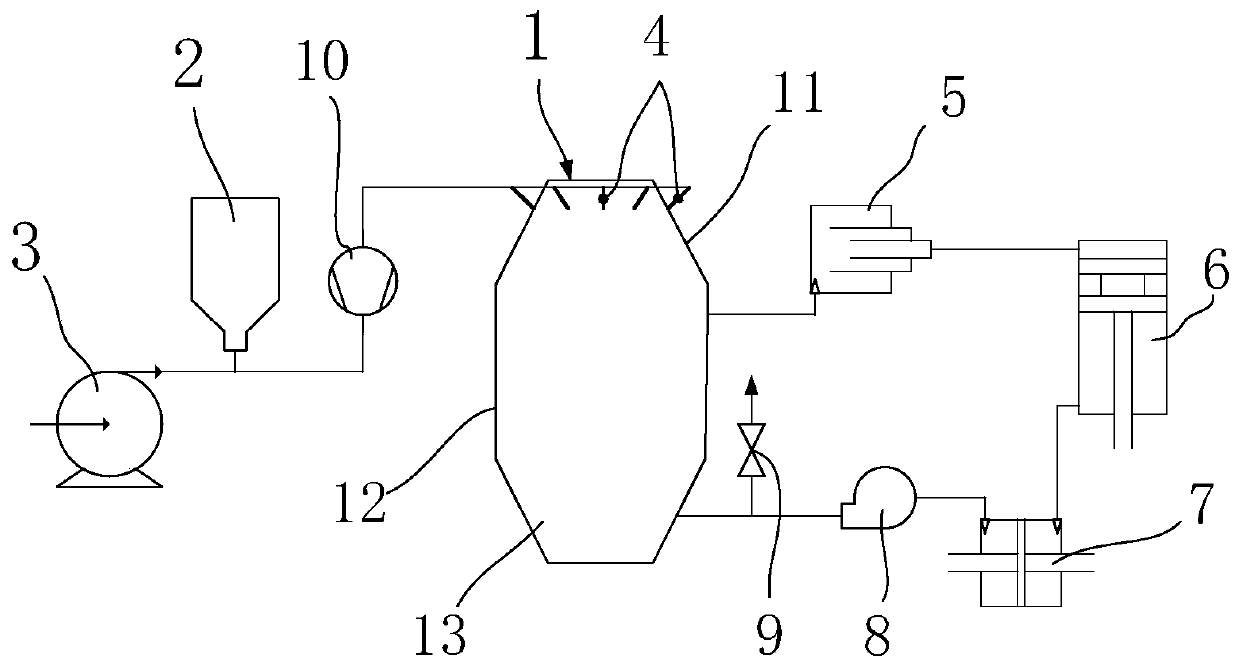

[0015] Such as figure 1 As shown, a CDQ furnace system with tail gas desulfurization function includes a furnace body 1, a desulfurizer bin 2, a pneumatic conveying device 3, a plurality of blowing pipes 4, a primary dust collector 5, a waste heat boiler 6, and a secondary dust collector 7 , Circulation fan 8, gas diffuser 9 and distributor 10.

[0016] Its working principle is: the powdery desulfurizer is transported to the top of the inner chamber of the furnace body, and the SO in the circulating gas in the furnace is mixed with the powdery desulfurizer during the falling process. 2 The reaction produces sulfate particles, some of which fall into the coke layer and are sent to the blast furnace to participate in smelting along with the coke, and the other part of the particles enters the dust collector with the circulating gas for dust removal and filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com