Target anchorage agent for sulfide in oil and preparation method and application thereof

A technology of sulfide and anchoring agent, applied in chemical instruments and methods, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problem of not finding magnetic nanoparticles and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

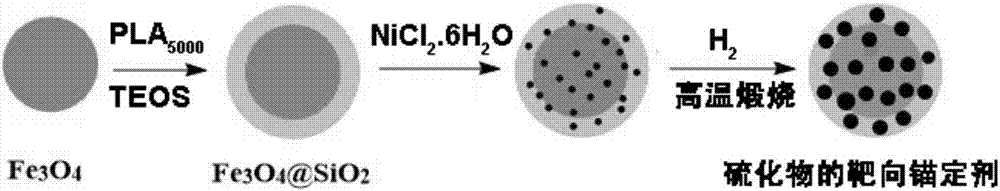

[0051] The present embodiment provides a sulfide targeting anchoring agent, which is prepared by the following steps:

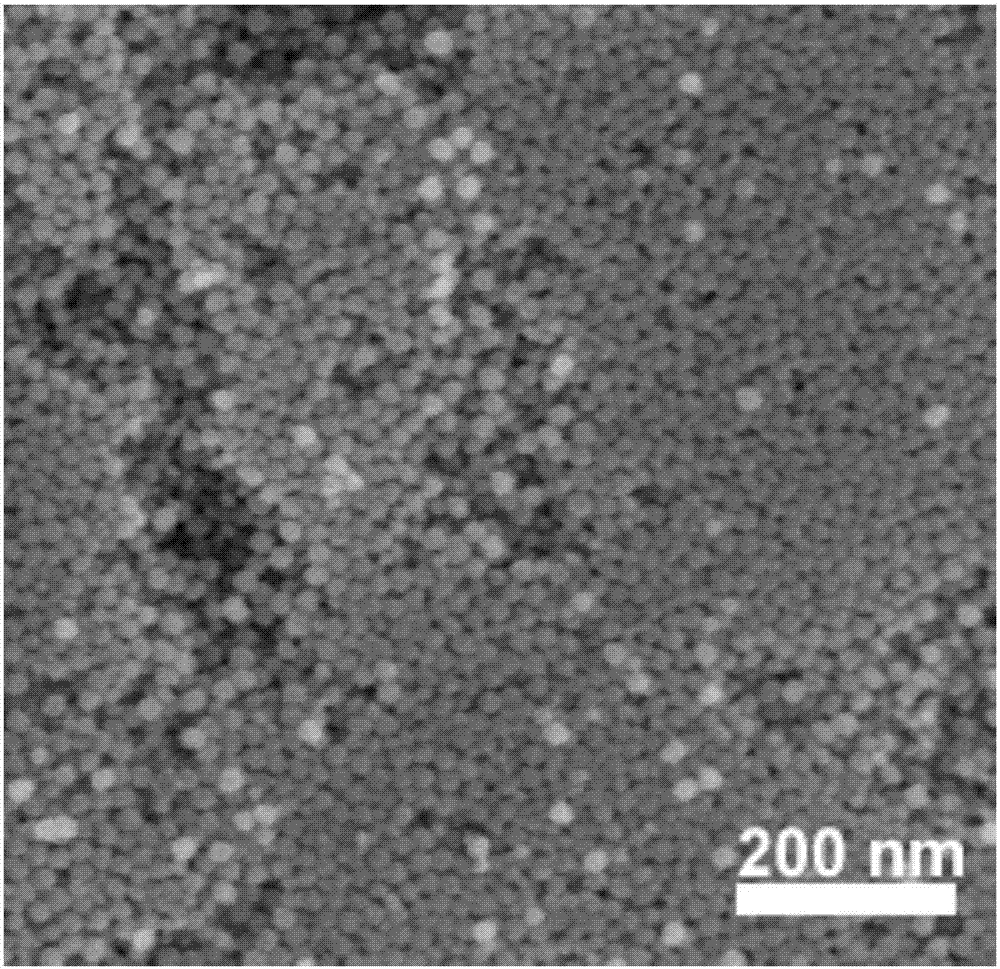

[0052] 1. Preparation of superparamagnetic nanoparticles

[0053] Mix 5mmol of iron acetylacetonate (FeAcAc), 10mL of oleic acid, 10mL of oleylamine and 10mL of octadecene; heated to 300°C under argon protection, the reaction was refluxed for 3 hours to obtain a black solution; after cooling, a large amount of ethanol was added to precipitate, The product was collected under the action of a magnetic field and dried to obtain superparamagnetic Fe 3 O 4 nanoparticles.

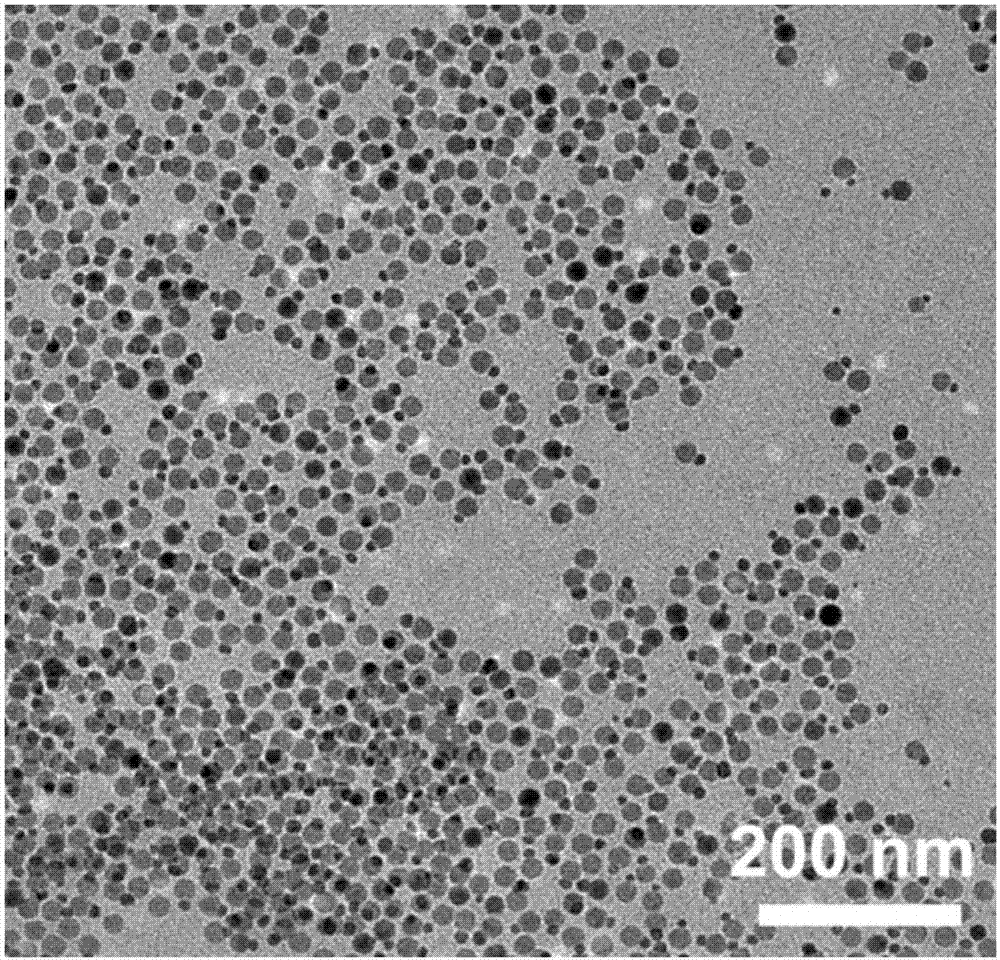

[0054] 2. Preparation of superparamagnetic nanoparticles coated with silica shell

[0055] superparamagnetic Fe 3 O 4 Nanoparticles and polylactic acid (PLA) with a molecular weight of 5000 5000 ) was dispersed in chloroform at a mass ratio of 1:5, heated to 80°C and refluxed for 5 hours; after cooling, magnetic nanoparticles were collected under the action of an external magnetic field to...

Embodiment 2

[0062] The present embodiment provides a sulfide targeting anchoring agent, which is prepared by the following steps:

[0063] 1. Preparation of FePt nanoparticles

[0064] 2.5mmol carbonyl iron Fe(Co) 5 , 2.5mmol platinum acetylacetonate Pt(AcAc), 10mL oleic acid, 5mL oleylamine and 7.5mL octadecene were mixed; heated to 310 ℃ under argon protection, the reaction was refluxed for 2 hours to obtain a black solution; after cooling, a large amount of ethanol was added to precipitate , the product was collected under the action of an external magnetic field, and FePt nanoparticles were obtained after drying.

[0065] 2. Preparation of FePt nanoparticles coated with silica shell

[0066] FePt nanoparticles were combined with polylactic acid (PLA) with a molecular weight of 5000. 5000 ) was dispersed in chloroform at a mass ratio of 1:6, heated to 80 °C and refluxed for 3 hours; after cooling, magnetic nanoparticles were collected under the action of an external magnetic field t...

Embodiment 3

[0073] The present embodiment provides a sulfide targeting anchoring agent, which is prepared by the following steps:

[0074] 1. NiFe 2 O 4 Preparation of nanoparticles

[0075] Mix 5mmol Fe(AcAc), 2.5mmol 2.5mmol platinum Pt(AcAc), 7.5mL oleic acid, 2.5mL oleylamine and 10mL octadecene; heat to 300°C under argon protection, the reaction is refluxed A black solution was obtained in 2 hours; after cooling, a large amount of ethanol was added for precipitation, the product was collected under the action of an external magnetic field, and NiFe was obtained after drying 2 O 4 nanoparticles.

[0076] 2. Preparation of NiFe coated with silica shell 2 O 4 Nanoparticles

[0077] the NiFe 2 O 4 Nanoparticles and polylactic acid (PLA) with a molecular weight of 5000 5000 ) was dispersed in chloroform at a mass ratio of 1:4, heated to 80°C and refluxed for 4 hours; after cooling, magnetic nanoparticles were collected under the action of an external magnetic field to obtain PLA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com