Biogas in-situ desulfurization biological agent

A biological agent, biological agent technology, applied in the field of desulfurization agent, can solve the problems of inability to desulfurize, short service period, frequent replacement, etc., and achieve the effect of rapid desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

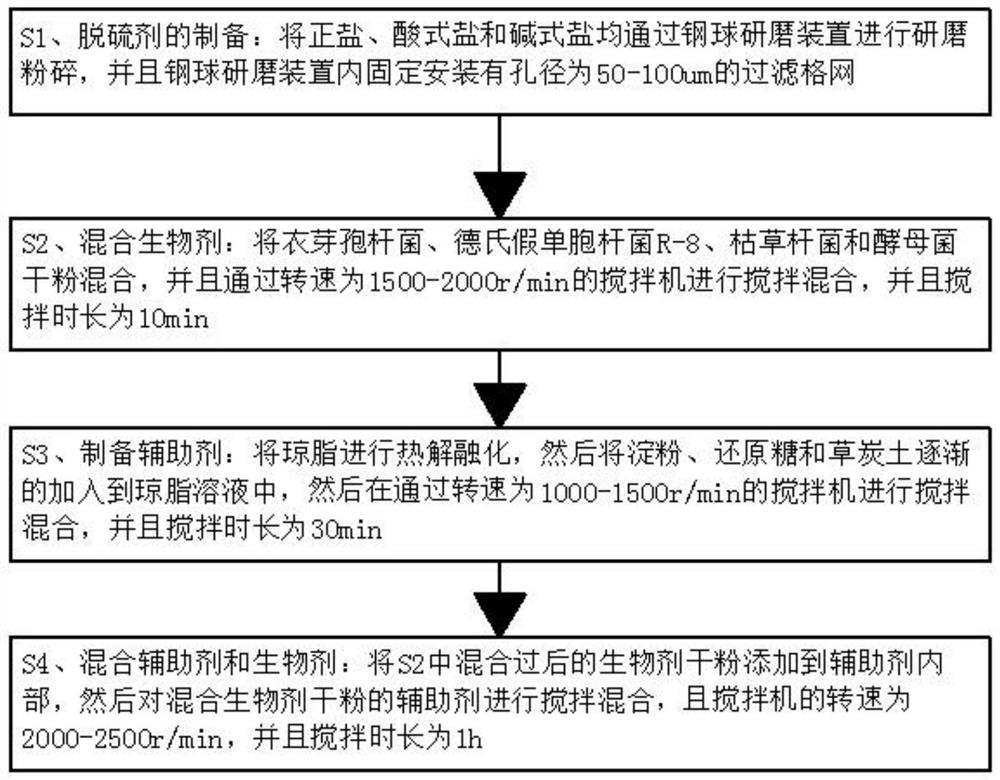

Method used

Image

Examples

Embodiment 1

[0027] A biogas in-situ desulfurization biological preparation, including desulfurization agent, biological agent and auxiliary agent, the desulfurization agent uses iron salt, and the iron salt includes normal salt, acid salt and basic salt. one or more;

[0028] The biological agent adopts various microbial mixed strains, and the biological agent includes a mixture of Bacillus tunica, Pseudomonas delbrueckii R-8, Bacillus subtilis and yeast to form a biological agent;

[0029] The auxiliary agent includes a mixture of agar, starch, reducing sugar and peat soil, etc., and the auxiliary agent is mixed with the biological agent to form a diameter of 50um.

[0030] In order to enable the desulfurizer to automatically adjust according to the internal environment of different biogas digesters and adapt to different acidity and alkalinity, in this embodiment, preferably, the normal salt includes ferric chloride, ferric sulfate, ferric nitrate, citric acid One or more of iron, the ...

Embodiment 2

[0044] A biogas in-situ desulfurization biological preparation, including desulfurization agent, biological agent and auxiliary agent, the desulfurization agent uses iron salt, and the iron salt includes normal salt, acid salt and basic salt. one or more;

[0045] The biological agent adopts various microbial mixed strains, and the biological agent includes a mixture of Bacillus tunica, Pseudomonas delbrueckii R-8, Bacillus subtilis and yeast to form a biological agent;

[0046] The auxiliary agent includes a mixture of agar, starch, reducing sugar and peat soil, etc., and the auxiliary agent is mixed with the biological agent to form a diameter of 100um.

[0047] In order to enable the desulfurizer to automatically adjust according to the internal environment of different biogas digesters and adapt to different acidity and alkalinity, in this embodiment, preferably, the normal salt includes ferric chloride, ferric sulfate, ferric nitrate, citric acid One or more of iron, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com