Preparation method of solid catalyst for catalyzing glucose dehydration

A solid catalyst, glucose technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., to reduce production costs, reduce environmental pollution, and facilitate reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, chitosan and SBA-15 were added to water at a ratio of 1:1, and the water was slowly evaporated while stirring at 80°C to obtain solid particles; Calcined (heating rate 5°C / min, heat preservation 1h), a black solid powder was obtained. The black solid powder was soaked in 5% HF solution to remove SBA-15, then filtered, washed with deionized water for several times until hydrofluoric acid was washed, and finally dried in an oven at 80°C for 10 hours to obtain a mesoporous carbon nitrogen material. Soak the prepared carbon-nitrogen material in 5mol / L hydrochloric acid for 24 hours, filter it, wash it with deionized water several times until the excess acid is washed away, and finally dry it in an oven at 90°C for 12 hours to obtain a solid that is used to catalyze the dehydration of glucose catalyst.

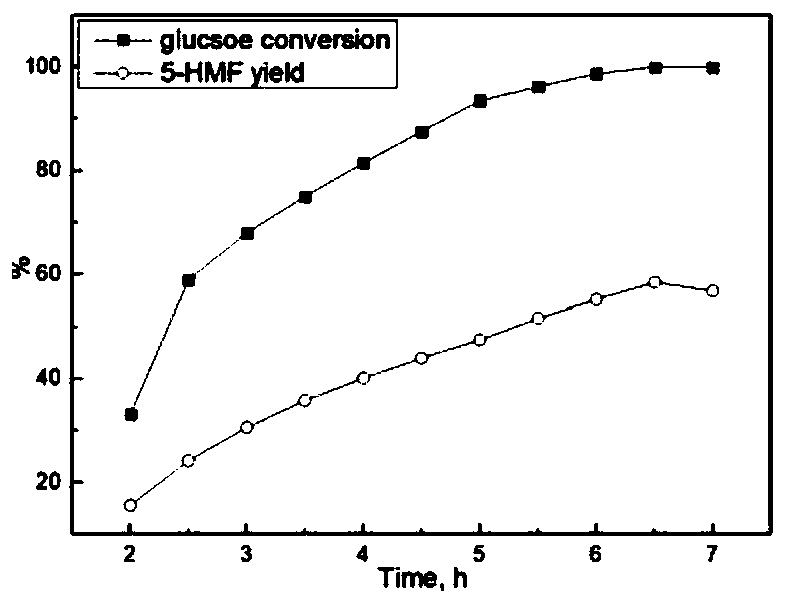

[0039] Catalytic performance analysis test:

[0040] Dissolve 0.1g of glucose in 4ml of water and 8ml of methyl isobutyl ketone, then add 0.2g of solid catalyst for...

Embodiment 2

[0047] First, chitosan and SBA-15 were added to water at a ratio of 1:3, and the water was slowly evaporated while stirring at 82°C to obtain solid particles; Calcination (heating rate 2°C / min, heat preservation 1h) to obtain a black solid powder. The black solid powder was soaked in 8% HF solution to remove SBA-15, then filtered, washed with deionized water for several times until hydrofluoric acid was washed, and finally dried in an oven at 86°C for 15 hours to obtain a mesoporous carbon nitrogen material. Soak the prepared carbon-nitrogen material in 5mol / L hydrochloric acid for 26 hours, filter it, wash it with deionized water several times until the excess acid is washed away, and finally dry it in an oven at 80°C for 10 hours to obtain a solid for catalyzing the dehydration of glucose catalyst.

[0048] Catalytic performance analysis test:

[0049] Dissolve 0.1g of glucose in 4ml of water and 8ml of methyl isobutyl ketone, then add 0.2g of solid catalyst for catalyzing...

Embodiment 3

[0052] First, chitosan and SBA-15 were added to water at a ratio of 1:2, and the water was slowly evaporated while stirring at 85°C to obtain solid particles; Calcination (heating rate 6°C / min, heat preservation 1h) to obtain a black solid powder. Soak the black solid powder in 6% HF solution to remove the SBA-15 template, then filter it, wash it with deionized water several times until it is washed with hydrofluoric acid, and finally dry it in an oven at 90°C for 18 hours to obtain a mesoporous carbon nitrogen material . Soak the prepared carbon-nitrogen material in 5mol / L hydrochloric acid for 24 hours, filter it, wash it with deionized water several times until the excess acid is washed away, and finally dry it in an oven at 100°C for 12 hours to obtain a solid for catalyzing the dehydration of glucose catalyst.

[0053] Catalytic performance analysis test:

[0054] Dissolve 0.1g of glucose in 4ml of water and 8ml of methyl isobutyl ketone, then add 0.2g of solid catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com