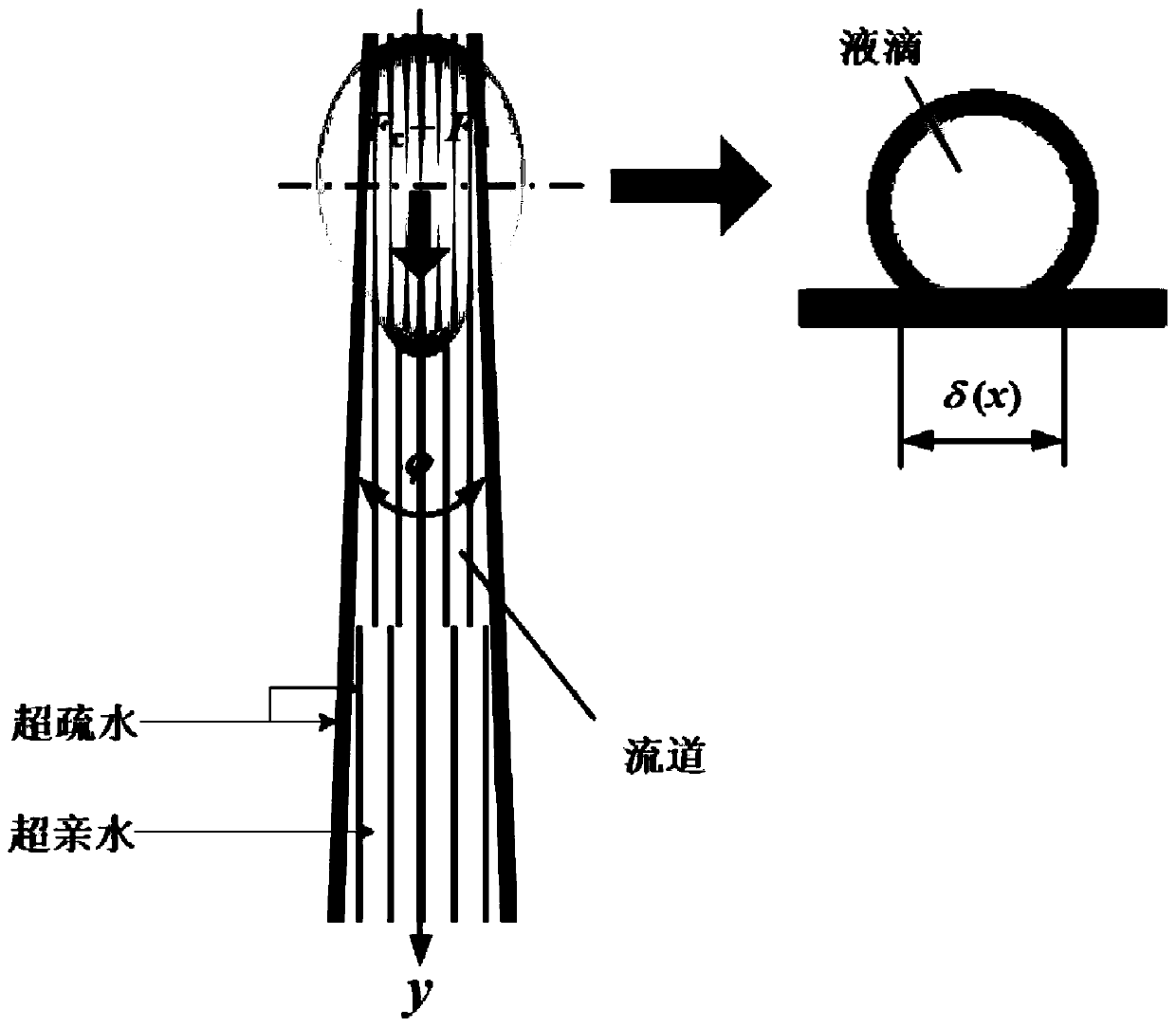

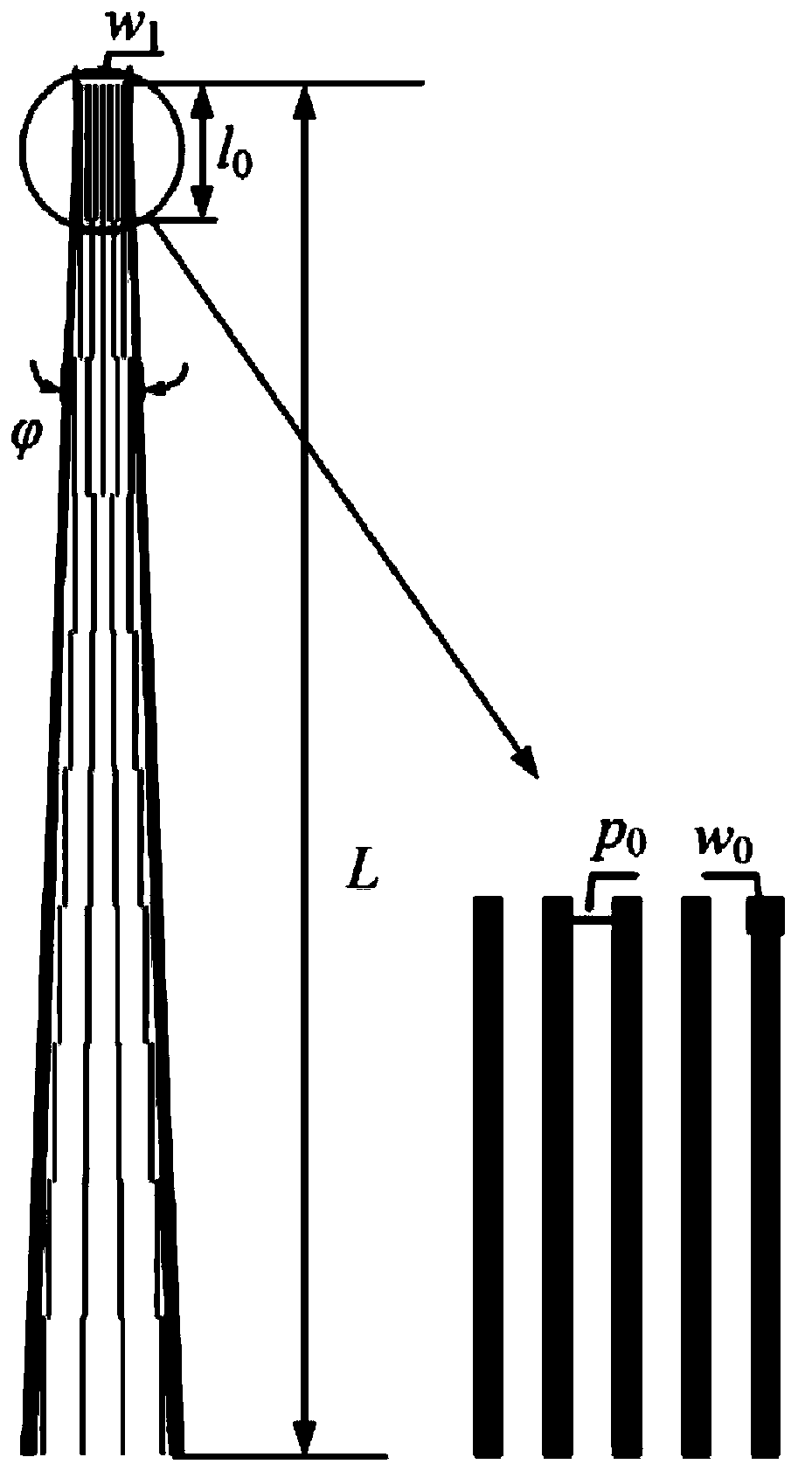

Self-driven paper-based micro-fluidic chip composed based on strip-shaped gradient array and wedge-shaped flow channel

A microfluidic chip and wedge flow technology, applied to laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of insufficient precision, increasing gap between hydrophilicity and hydrophobicity, etc., and achieve simple operation and simple equipment , low-cost production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

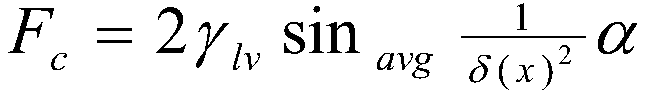

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a self-driven paper-based microfluidic chip based on a strip-shaped gradient array and a wedge-shaped flow channel, comprising the following steps:

[0032] 1) Preparation of superhydrophobic titanium dioxide nanoparticle suspension: disperse 0.1 g of titanium dioxide powder with a particle size of about 25 nm in 10 mL of ethanol, and ultrasonically disperse it for 1 h to make it uniform; Oxysilane) was added to the dispersion, ultrasonicated for 10 minutes, and reacted at room temperature for 12 hours to obtain a silanized titanium dioxide nanoparticle suspension.

[0033] 2) Prepare the paper substrate of the superhydrophobic microfluidic chip with micro-nano composite structure: cut the filter paper into small pieces of 1.5cm3cm, then soak the filter paper in the silane-treated dispersion, take it out after 5min, and dry it naturally at room temperature; repeat Such operations are performed three times to obtain a superhydrophobic filter paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com