Environment-friendly permanent polyolefin flame-retardant cable material and preparation method thereof

A flame retardant cable material, polyolefin technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of moisture absorption, precipitation, unfavorable industrial production, etc., and achieve high flame retardant efficiency and low addition amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

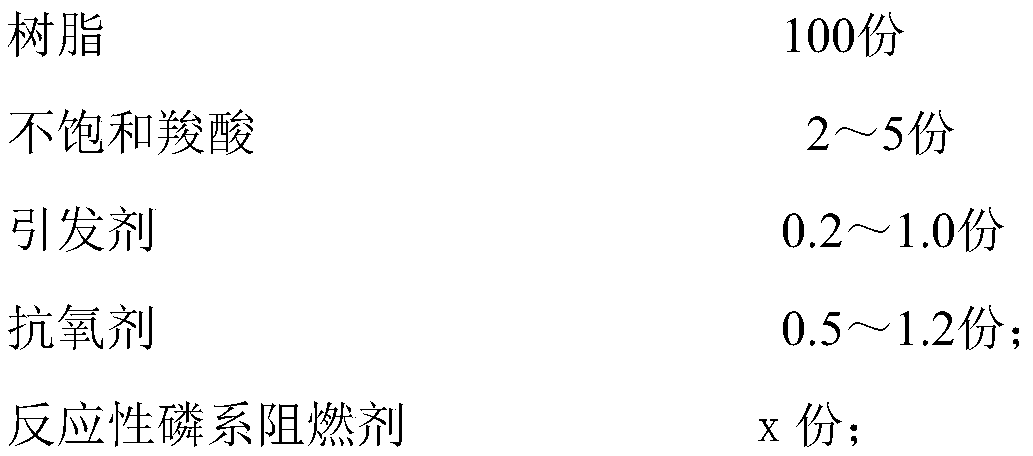

[0026] Recipe: parts by weight:

[0027]

[0028] (1) Mix the raw materials except DOPO, extrude through twin-screw from zone 1 to zone 5 at temperatures of 150°C, 170°C, 190°C, 200°C, 210°C, melt kneading, graft copolymerization, After strand cutting, granulation and drying, the raw material of polyolefin grafted unsaturated carboxylic acid is obtained;

[0029] Described polyethylene resin is linear low density polyethylene (LLDPE), and its melt index is 2.2g / 10min;

[0030] Described unsaturated carboxylic acid is acrylic acid;

[0031] Described initiator is dicumyl peroxide;

[0032] The antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0033] (2) Mix polyolefin grafted unsaturated carboxylic acid raw material with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) phosphorus flame retardant, add DOPO, After mixing, it is added to the twin-screw extruder, and the temperature in the first zone to the fifth zon...

Embodiment 2

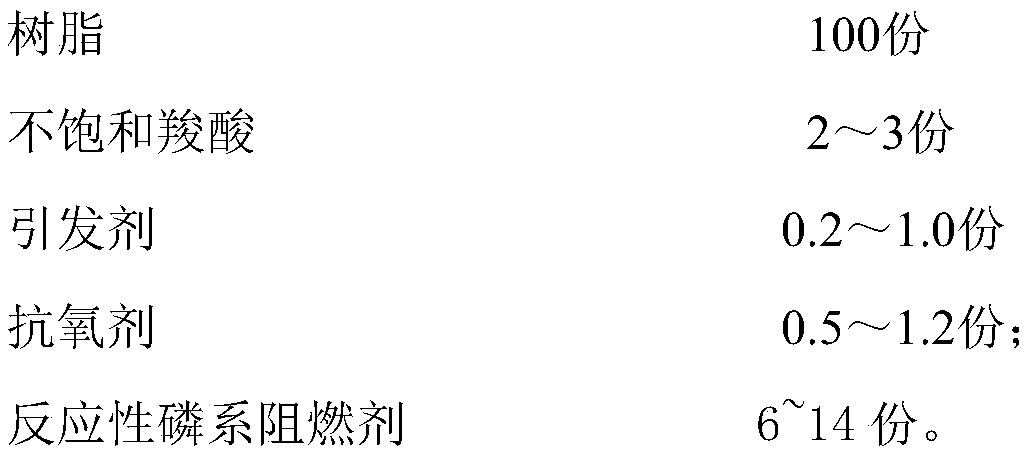

[0035] formula:

[0036]

[0037] The preparation method is the same as in Example 1.

Embodiment 3

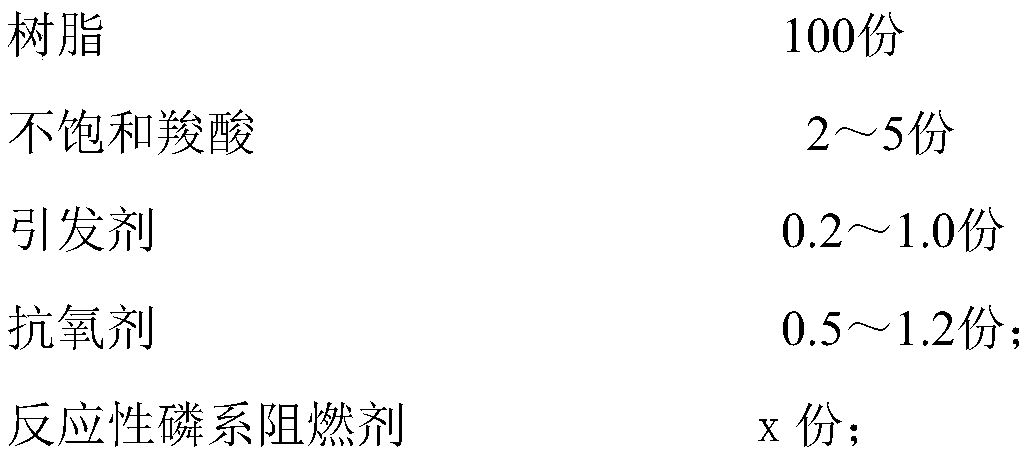

[0039] formula:

[0040]

[0041] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com