Automatic azo dye production process

A production process and technology of azo dyes, applied in the direction of azo dyes, monoazo dyes, organic dyes, etc., can solve the problems of high production cost and low product purity, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

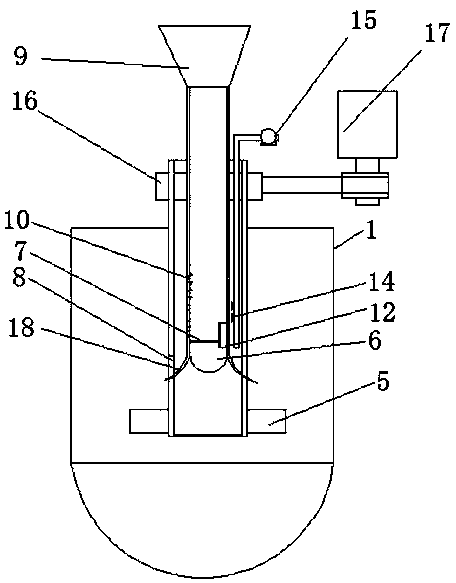

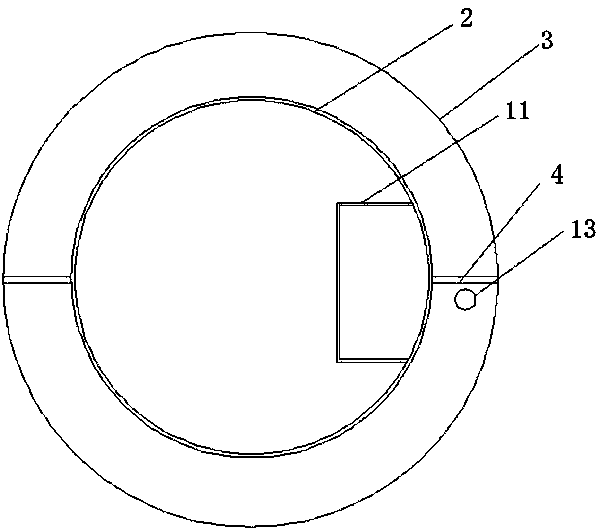

[0027] Such as figure 1 , figure 2 As shown, a kind of azo dye automatic production process provided by the invention comprises:

[0028] 1) Add 43kg of 1500LL ammonia water with a mass percentage of 20% to the diazo kettle, then raise the temperature to 30°C, pour 110kg of 2B acid, stir to make it transparent, then add ice to cool down to below 0°C, add 30% hydrochloric acid 150kg, after stirring for 15 minutes, add ice and water to cool down to below 0°C, adjust the volume to 3000L, add 30% sodium nitrite aqueous solution within 20 minutes; stir and react for 30 minutes, add CaCl 2 220kg aqueous solution, and then stirred for 20min, the storage temperature is below 0°C, and the total volume at this time is 3300L; the CaCl 2 120kg CaCl dissolved in aqueous solution 2 .

[0029] 2) Put 1500-1700L of water in the dissolution kettle, add 190kg of 30% sodium hydroxide aqueous solution; heat up to 60°C, pour 3-hydroxy-2-naphthoic acid, stir to dissolve, add water to adjust th...

Embodiment 2

[0040] An automatic production process for azo dyes provided by the present invention includes: 1) Add 45kg of 1700L ammonia water with a mass percentage of 20% to the diazo kettle, then raise the temperature to 30°C, pour 130kg of 2B acid, and stir to dissolve it to Transparent, then add ice and cool down to below 0°C, add 170kg of 30% hydrochloric acid, stir for 15 minutes, add ice and water to cool down to below 0°C, adjust the volume to 3000L, add 30% sodium nitrite within 20 minutes Aqueous solution; stir and react for 30min, add CaCl 2 240kg of aqueous solution, and then stirred for 20min, the storage temperature is below 0°C, and the total volume at this time is 3500L; the CaCl 2 120kg CaCl dissolved in aqueous solution 2 .

[0041] 2) Put 700L of water in the dissolution kettle, add 210kg of 30% sodium hydroxide aqueous solution; heat up to 60°C, pour 3-hydroxy-2-naphthoic acid, stir to dissolve, add water to adjust the volume to 2500L;

[0042] 3) Add 120L of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com