Continuous on-line preparation method of ultrahigh strength and toughness Mn-B steel structural part

A steel structure, ultra-high-strength technology, applied in the field of steel stamping and forming, can solve the problems of reducing the price of hot-formed parts and popularizing applications, which is not conducive to welding performance, and increasing the cost of raw materials, so as to reduce construction investment costs, fast heating speed, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The continuous on-line preparation method of ultra-high strength and toughness Mn-B steel structure provided by the embodiment of the present invention includes:

[0064] The continuous transmission of the electrode roller is used to carry out cyclic heating-quenching of the Mn-B steel strip, so that the high-temperature austenite and martensite grains after quenching are ultra-fine.

[0065] At the same time, the high-speed heating of the self-resistance heating method is carried out during the continuous transmission of the electrode roller.

[0066] And repeated heating-quenching is carried out to realize the uniform diffusion of elements.

[0067] Ultrafine grained austenite can be transformed into ultrafine grained martensite or ultrafine grained martensite + a small amount of bainite through the high cooling rate in the mold during the hot stamping forming pressure quenching process or the forced cooling method after stamping forming Body tissue, to realize the p...

Embodiment 1

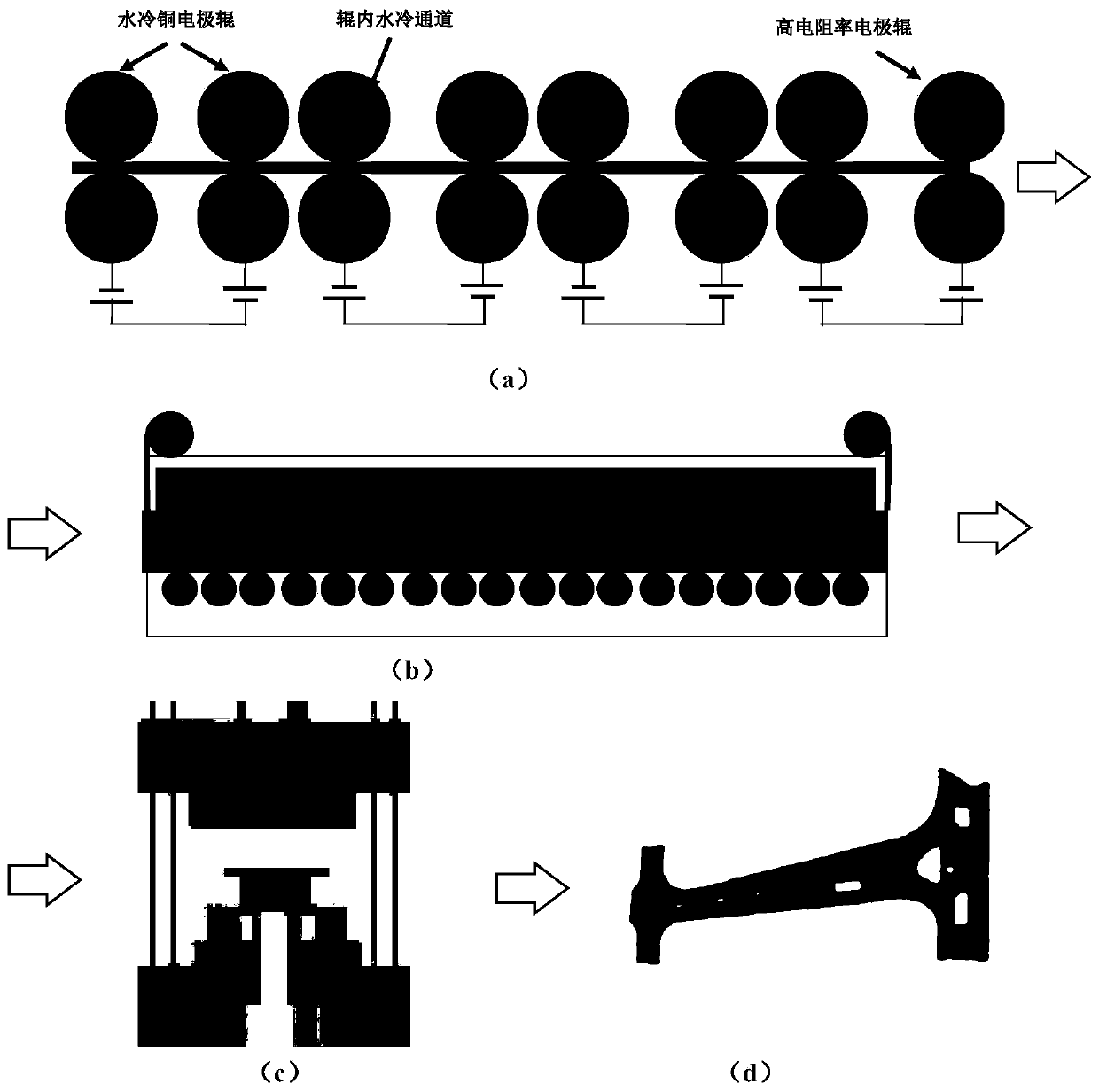

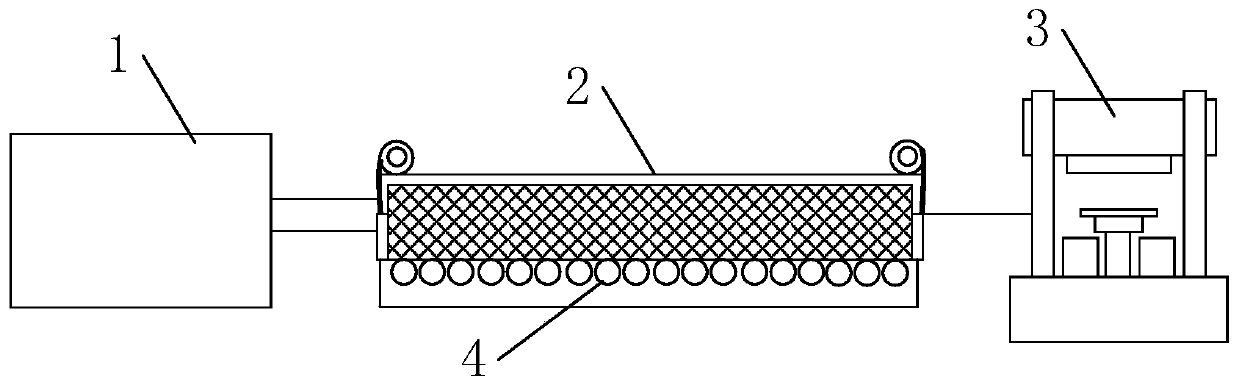

[0090] Such as figure 1 Shown; The continuous on-line preparation method of super high strength and toughness Mn-B steel structure provided by the invention comprises:

[0091] (1) Select a hot-rolled or cold-rolled non-coated plate with the appropriate thickness level required for weight reduction, and select a reasonable initial rectangular blank size according to the number of parts in the forming die under one stroke, but ensure a single blank plate has a maximum length of not less than figure 1 (a) The roller spacing of two pairs of self-resistance heating rollers, otherwise online heating cannot be completed.

[0092] (2) The billet is figure 1 The heating equipment shown in (a) implements continuous on-line cyclic heating and quenching process, in which the rapid heating process is realized by low-voltage and high-current loading between two adjacent pairs of electrode rollers, and then quenching and cooling are implemented when passing through the water-cooled electr...

Embodiment 2

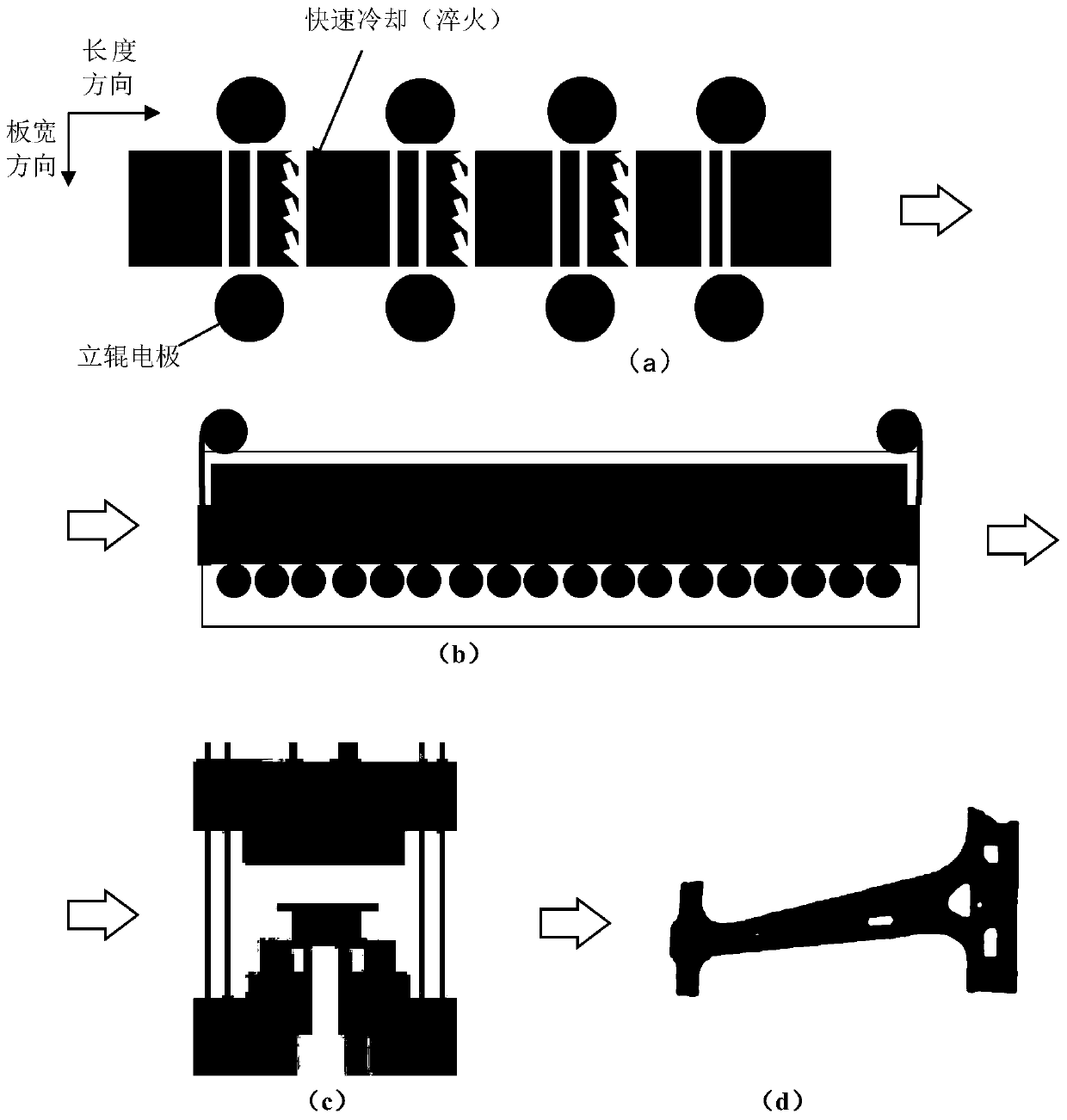

[0097] Such as figure 2 As shown, the continuous on-line preparation method of the ultrahigh-strength toughness Mn-B steel structure provided by the invention comprises:

[0098] (1) Select a hot-rolled or cold-rolled non-coated plate with the appropriate thickness level required for weight reduction, and select a reasonable initial rectangular blank size according to the number of parts in the forming die under one stroke.

[0099] (2) The billet is figure 2 The heating equipment shown in (a) implements continuous on-line cyclic heating and quenching process, in which the rapid heating process relies on the low voltage and high current generated between the electrodes of each pair of vertical rollers to achieve rapid temperature rise along the width direction of the plate, and then implements rapid cooling and quenching. In this way, multiple pairs of electrode rollers are passed continuously to realize multiple cyclic heating-quenching and cooling treatments on the blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com