High-strength low-alloy steel HX420 LAD+Z heat-based spangle-free zinc-plated plate

A low-alloy steel, high-strength technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of large performance and dimensional deviation, coating bonding force inspection, etc., to achieve stable performance and dimensional deviation , good surface quality, considerable social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

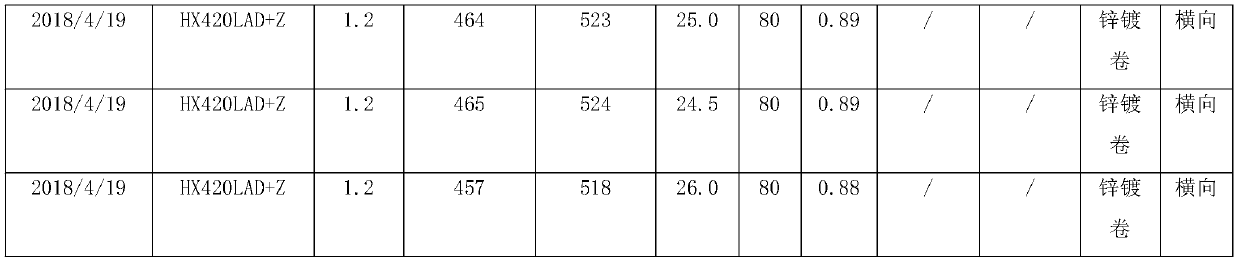

Embodiment 1

[0018] A high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet, including the following raw materials in mass percentages, C: 0.040-0.050%, Si: 0.15-0.20%, Mn: 1.1-1.20%, P: ≤0.012%, S: ≤0.003, Nb: 0.020-0.030, Ti: 0.010-0.015%, O: ≤0.004%, N: ≤0.0045%, the rest are iron and unavoidable impurities;

[0019] The method of high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet, the preparation steps are as follows: the galvanized raw material is pickled, leveled, heated, galvanized, skin-finished, and passivated using the PGL pickling and galvanizing continuous production line , coiled into hot-dip galvanized coils;

[0020] Preferably, the pickling process requirements of the PGL acid plating continuous production line: the HCL content in the acid tank is 60g / L, the total acid plating is 180-215g / L, and the pickling temperature is 82°C;

[0021] Preferably, the rinsing process requirements of the PGL acid plating continuou...

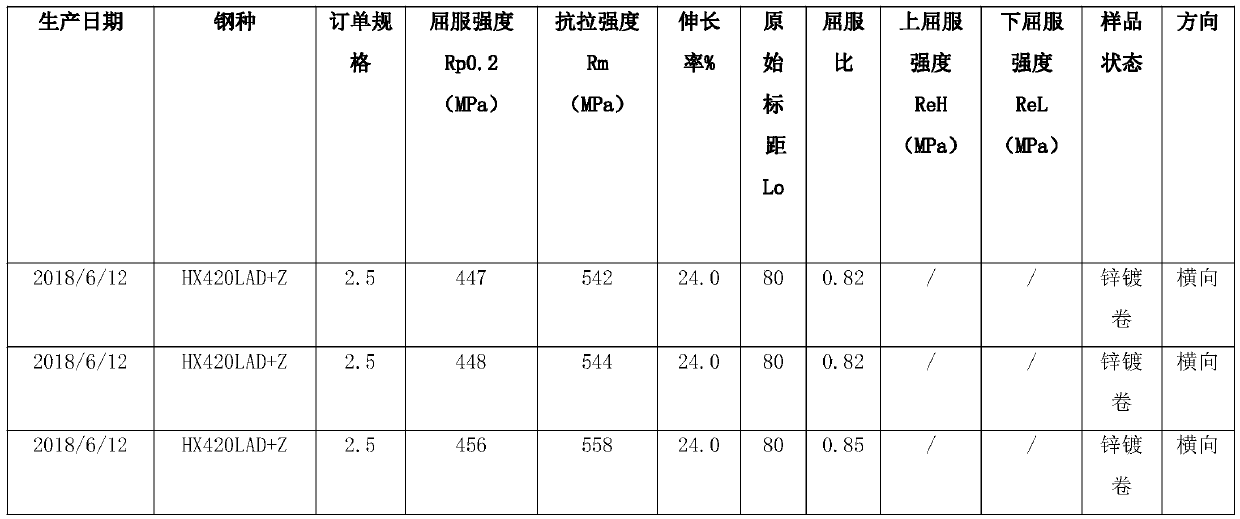

Embodiment 2

[0032] A high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet, including the following raw materials in mass percentages, C: 0.040-0.050%, Si: 0.15-0.20%, Mn: 1.1-1.20%, P: ≤0.012%, S: ≤0.003, Nb: 0.020-0.030, Ti: 0.010-0.015%, O: ≤0.004%, N: ≤0.0045%, the rest are iron and unavoidable impurities;

[0033] A production method of high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet. The preparation steps are as follows: the galvanized raw material is pickled, leveled, heated, galvanized, and skin-finished using a PGL pickling and galvanizing continuous production line. , passivation, and coiled into hot-dip galvanized coils;

[0034] Preferably, the pickling process requirements of the PGL acid plating continuous production line: the HCL content in the acid tank is 65g / L, the total acid plating is 180-215g / L, and the pickling temperature is 85°C;

[0035] Preferably, the rinsing process requirements of the PGL acid plat...

Embodiment 3

[0045] A high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet, including the following raw materials in mass percentages, C: 0.040-0.050%, Si: 0.15-0.20%, Mn: 1.1-1.20%, P: ≤0.012%, S: ≤0.003, Nb: 0.020-0.030, Ti: 0.010-0.015%, O: ≤0.004%, N: ≤0.0045%, the rest are iron and unavoidable impurities;

[0046] A production method of high-strength low-alloy steel HX420LAD+Z heat-based spangle-free galvanized sheet. The preparation steps are as follows: the galvanized raw material is pickled, leveled, heated, galvanized, and skin-finished using a PGL pickling and galvanizing continuous production line. , passivation, and coiled into hot-dip galvanized coils;

[0047] Preferably, the pickling process requirements of the PGL acid plating continuous production line: the HCL content in the acid tank is 70g / L, the total acid plating is 180-215g / L, and the pickling temperature is 85°C;

[0048]Preferably, the rinsing process requirements of the PGL acid plati...

PUM

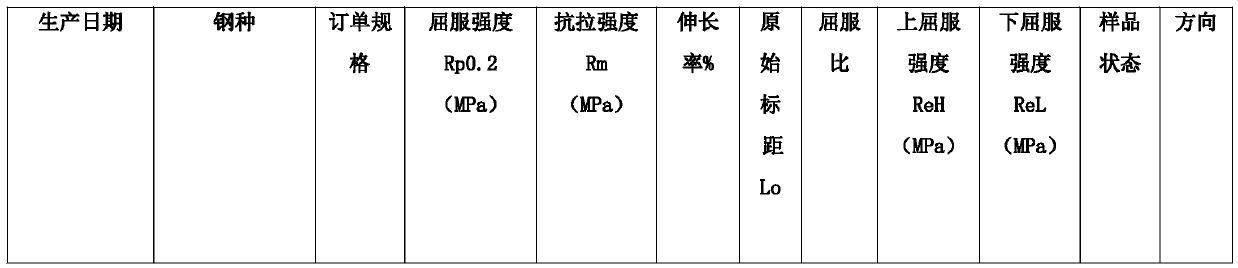

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com