Combustion furnace humidification system utilizing waste heat

A humidification system and waste heat technology, used in air humidification systems, household heating, heating methods, etc., can solve the problems of easy deformation and fracture of furnace bridges, and achieve the effect of not easy to deform and fracture, easy to use, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following specific implementation descriptions of the present invention are given with reference to the drawings;

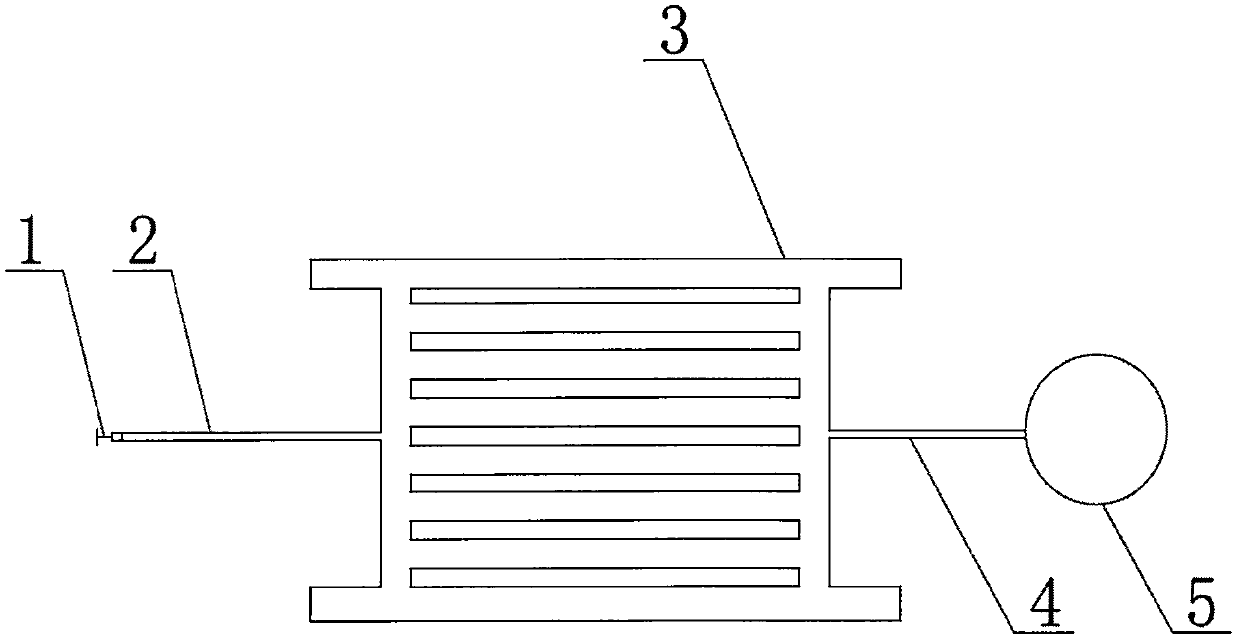

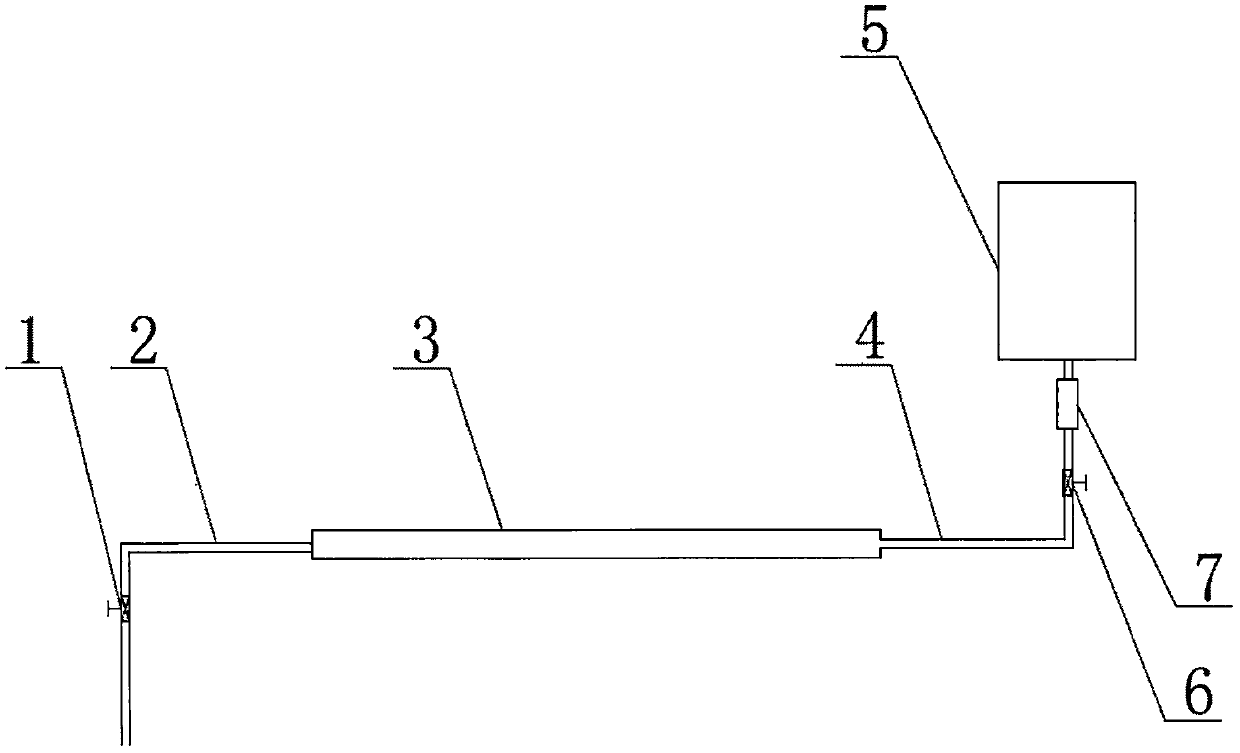

[0022] Such as figure 1 As shown, a furnace waste heat humidification system structure of the present invention includes a valve 1, a sewage pipe 2, a furnace bridge 3, a convection pipe 4, and a water tank 5. The furnace bridge 3 uses a frame made of interconnected hollow pipes, and the furnace bridge 3 is as a whole Sealed, there are inlet and outlet openings at both ends of the furnace bridge 3 frame, one end is connected to the sewage pipe 2, and the other end is connected to the convection pipe 4; the sewage pipe 2 is installed with a valve 1 for the furnace bridge 3 hollow pipe The discharge of air and waste water during water intake; figure 2 As shown, a valve 6 and a silencer 7 are connected to the convection pipe 4, and a water tank 5 is installed above the silencer 7;

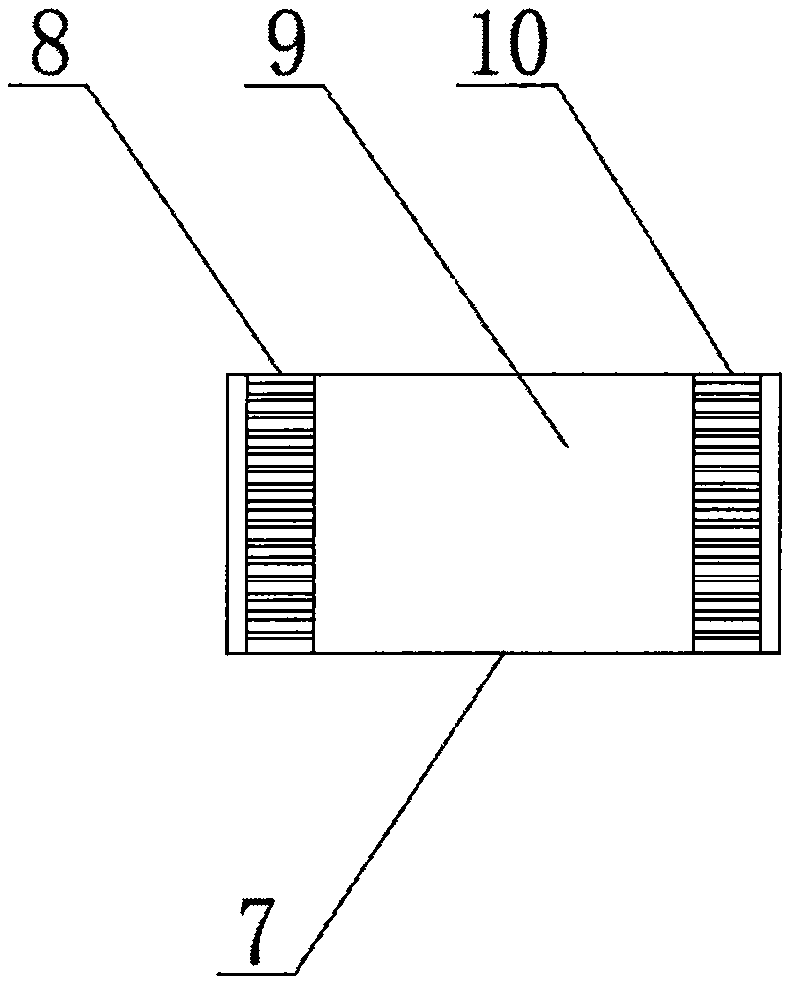

[0023] Such as image 3 As shown, the structure of the muffler 7 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com