Method for representing defect of two-dimensional material and application thereof

A two-dimensional material and defect technology, applied in the field of characterization of two-dimensional material defects, can solve the problems of small characterization area, low efficiency and high electron beam, and achieve the effect of large characterization area, high efficiency and fast imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Detection of WS by fluorescence lifetime imaging 2 defect

[0085] Two-dimensional material WS by mechanical exfoliation 2 Prepared on a release base.

[0086] Prepare samples with defects: use a plasma cleaner to introduce defects into the samples, the power of the plasma cleaner is 20W, the radio frequency is 13.56MH, and the sample is bombarded with argon gas for 10s.

[0087] Use the fluorescence lifetime imaging system (PicoHarp 300, PicoQuant) to perform fluorescence lifetime imaging detection on samples with defects, such as image 3 As shown, the excitation wavelength is 488nm, and the frequency is 40MHz. The objective lens (40X, NA 0.95) is used to focus the laser light to excite the sample. The generated fluorescence signal is collected by the same objective lens. Layer WS 2 The fluorescence lifetime of each spot is filtered, and the filtered optical signal is detected by a photodetector, and then the photodetector and laser are synchronized by a...

Embodiment 2

[0090] Example 2 confirms that defects make fluorescence lifetime longer

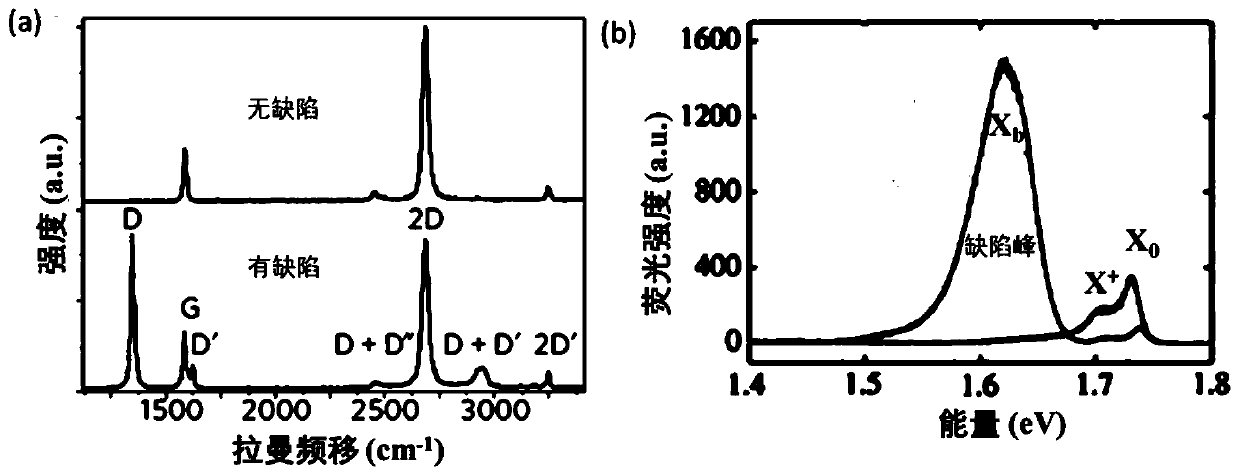

[0091] Raw single layer WS 2 The fluorescence spectrum of Figure 5 As shown, it can be seen that WS before plasma treatment 2 The fluorescence peak is superimposed by the neutral exciton peak and the trion peak, and a new peak appears after plasma treatment, that is, the defect state exciton peak.

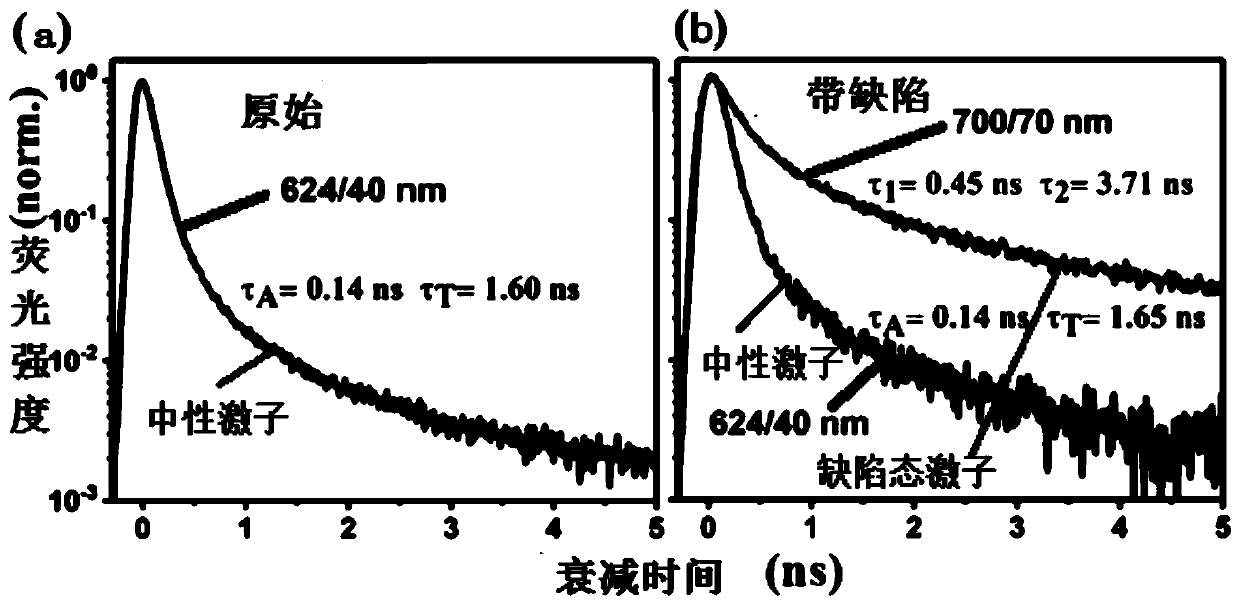

[0092] The time-resolved fluorescence lifetime decay curves for pristine and defect-bearing ones are as Figure 6 shown, from Figure 6 It can be seen that the decay rate of the defect state excitons is significantly reduced, and the fluorescence lifetime is significantly longer, indicating that the defect makes the fluorescence lifetime longer.

[0093] It can be seen that light excitation makes electrons transition from the ground state to the excited state, electrons relax and recombine with holes, and emit photons. When defects exist, defect fluorescence peaks can be generated. The defect fluorescen...

Embodiment 3

[0094] Example 3 Effect of defects on the exciton-exciton annihilation process in monolayer tungsten disulfide

[0095] The presence of defects also causes a decrease in the exciton-exciton annihilation (EEA) rate. Exciton-exciton annihilation is a process in which one exciton transfers energy to another exciton. It is a non-radiative process, so it can shorten the fluorescence lifetime, and the exciton annihilation rate can be obtained through data processing. When the defects exist, the intrinsic excitons in the sample can be bound to form defect state excitons, which will reduce the number of intrinsic excitons, so the number of excitons used to participate in the exciton annihilation process decreases, and the annihilation rate decreases.

[0096] Figure 7 is the effect of different excitons on the exciton-exciton annihilation, Figure 7 In (a) the fluorescence spectrum weights of neutral excitons, trion excitons, and defect state excitons are given as a function of las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Excitation wavelength | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com