Aroma-flavored sustained-release gel particles for cigarette filter stick, preparation and application thereof

A slow-release gel, cigarette filter rod technology, applied in the application, e-liquid filter, tobacco and other directions, can solve the problems of inconsistent rubber thickness, harsh material selection, easy volatilization of aroma, and reduce volatilization and effectively release aroma. , The selection of materials is not harsh, and the appearance quality is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Flavoring slow-release gel particles for cigarette filter rods, the preparation method is as follows:

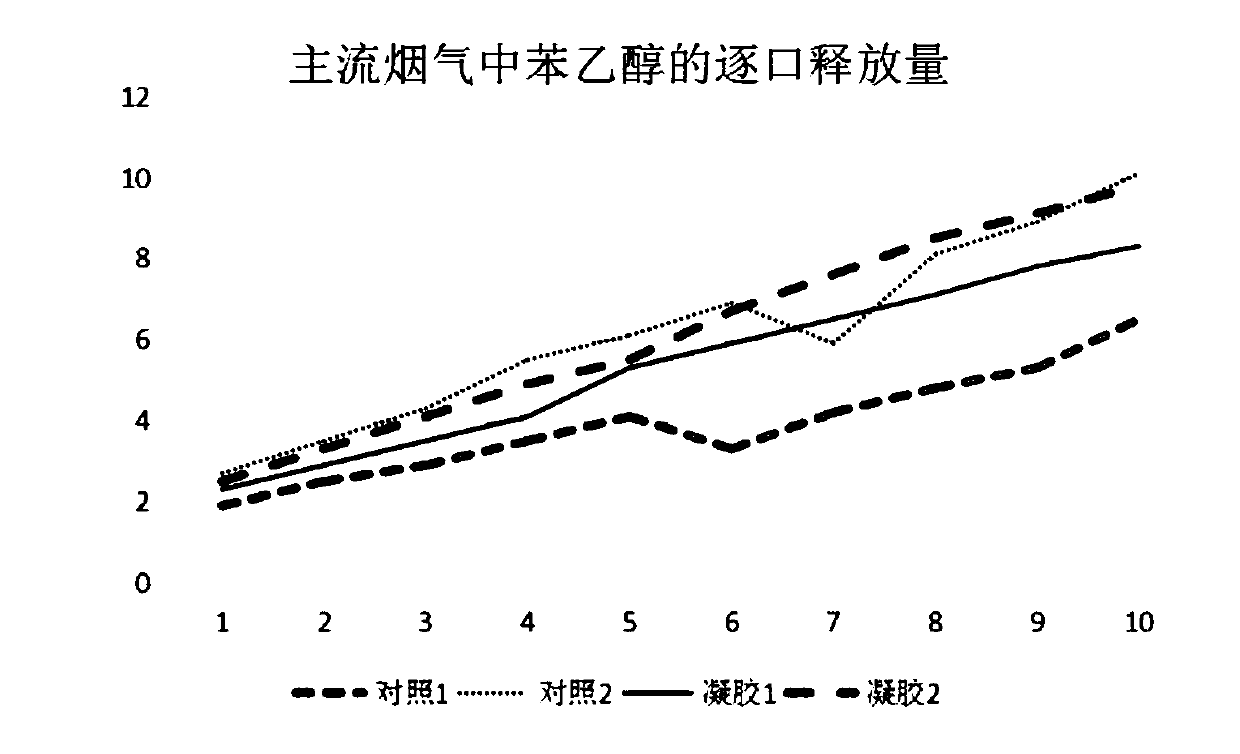

[0028] Configure the raw material solution: melt and mix 20% of myristic acid, 60% of palmitic acid and 20% of polycaprolactone at a temperature of 45-70°C to obtain a gel solution; then add 10% of the gel solution % phenylethyl alcohol to obtain a flavored slow-release gel solution with a viscosity of 480-500mpa.s. The used myristic acid, palmitic acid and polycaprolactone are all commercially available products, such as the product named myristic acid / myristic acid sold by Guangzhou Suixin Co., Ltd., and the product sold by Shanghai Zhanyun Chemical Co., Ltd. It is a product of palmitic acid / palmitic acid, and the product sold by Dongguan Xialiang Plastic Co., Ltd. is called polycaprolactone PCL. The selected raw materials are food grade and pharmaceutical grade. The product is safe and pollution-free.

[0029] (2) Spray drying and granulation: pump the flavored ...

Embodiment 2

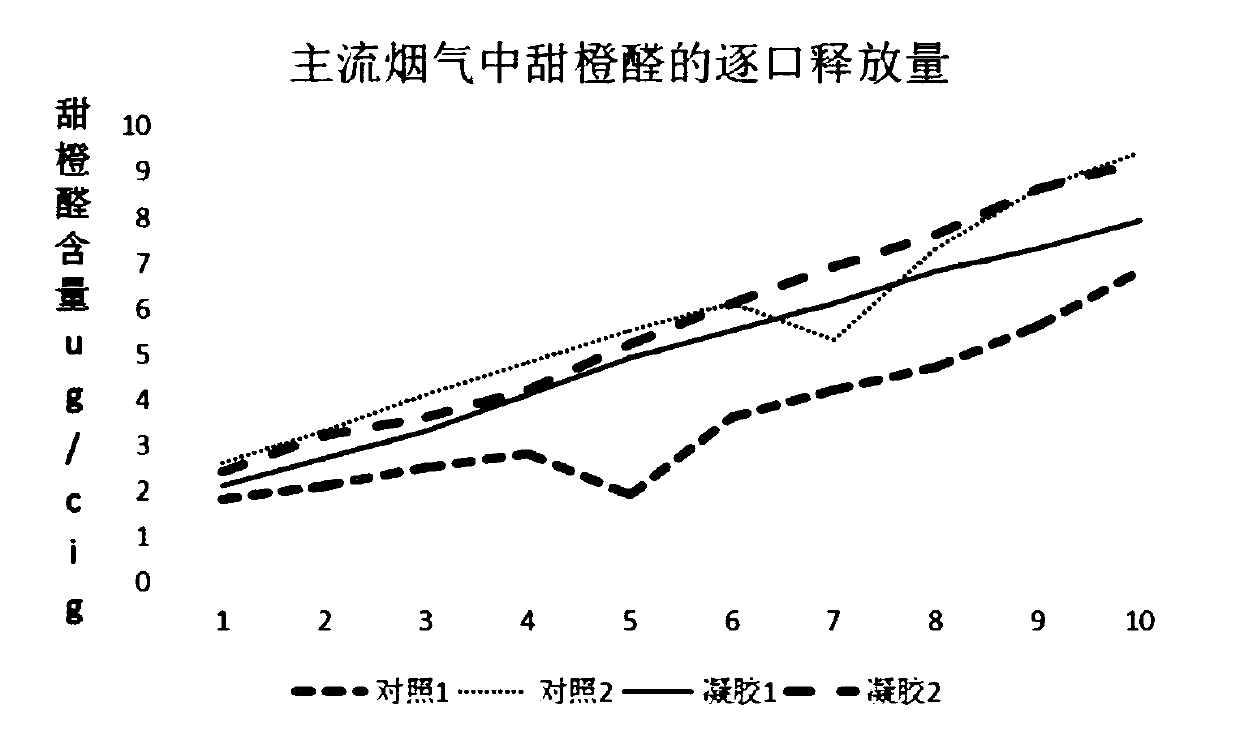

[0039] Flavoring and slow-release gel particles for cigarette filter sticks, the preparation method is as follows: 20% by mass of myristic acid, 50% of palmitic acid and 30% of polycaprolactone are melted and mixed at a temperature of 45-70°C uniform to obtain a gel solution; then add neral with a mass of 8% of the gel solution to obtain a flavored slow-release gel solution with a viscosity of about 420mpa.s. The prepared flavoring sustained-release gel solution is sent to a spray drying device to prepare 40-60 mesh particles.

[0040] The resulting flavored slow-release gel particles were tested and evaluated for the retention and release efficacy of neral, and the results were: the content of neral in the gel particle sample was reduced by about 14.13%, and the aroma could be released evenly, and the release effect was good, while The content of neral in the control sample was reduced by about 27.65%, and the aroma release was uneven and fluctuated. It shows that the gel pa...

Embodiment 3

[0042] Flavoring slow-release gel particles for cigarette filter sticks, the preparation method is as follows: 19% of myristic acid, 70% of palmitic acid and 11% of polycaprolactone are melted and mixed at a temperature of 45-70°C uniform to obtain a gel solution; then add 1% citral in the mass of the gel solution to obtain a flavored slow-release gel solution with a viscosity of about 50 mpa.s. The prepared flavoring sustained-release gel solution is sent to a spray drying device to prepare granules with a mesh size of 10-20.

[0043] The resulting flavored slow-release gel particles were tested and evaluated for the retention and release efficacy of citral, and the results were: the content of citral in the gel particle samples was reduced by about 13.21%, and the aroma could be released evenly, with a good release effect, while the control sample The content of citral decreased by about 30.27%, and the aroma release was uneven and fluctuated. It shows that the gel particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com