Adsorbent for enriching polyunsaturated fatty acids and ester products thereof as well as preparation method and application of adsorbent

A technology of unsaturated fatty acid and adsorbent, applied in the field of adsorbent and its preparation, to achieve the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

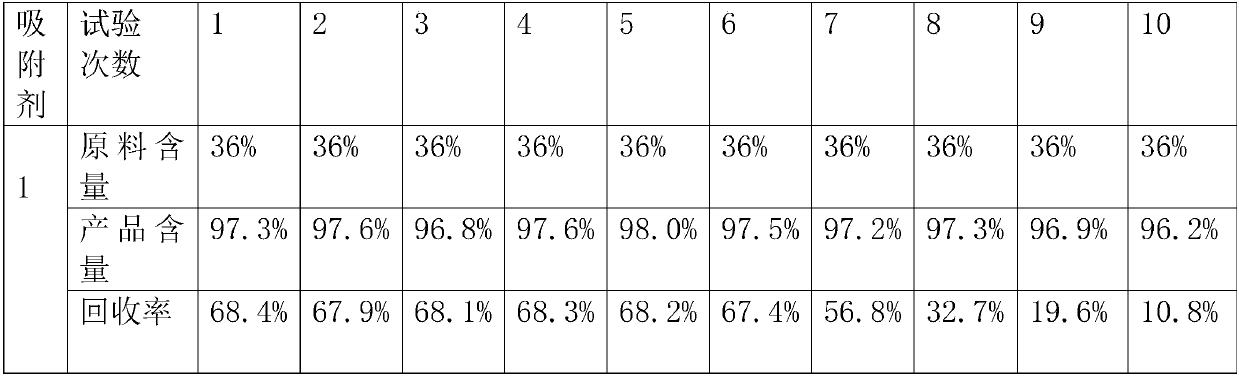

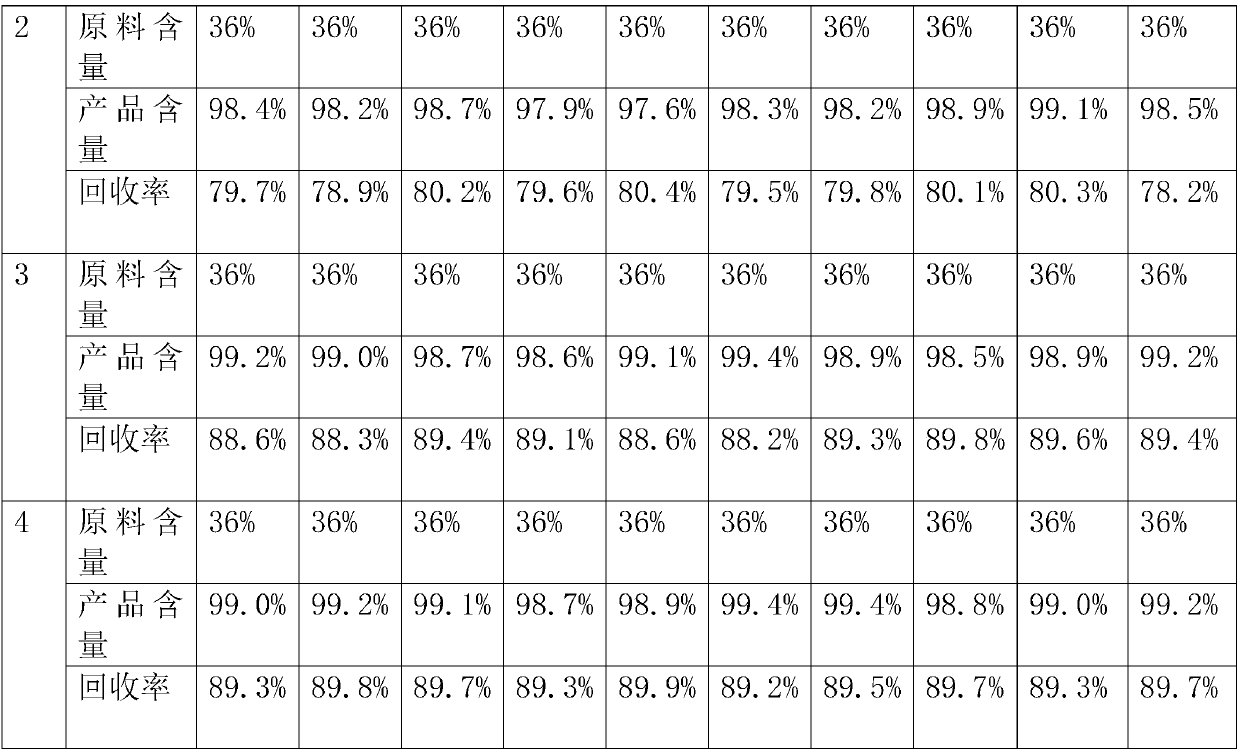

Examples

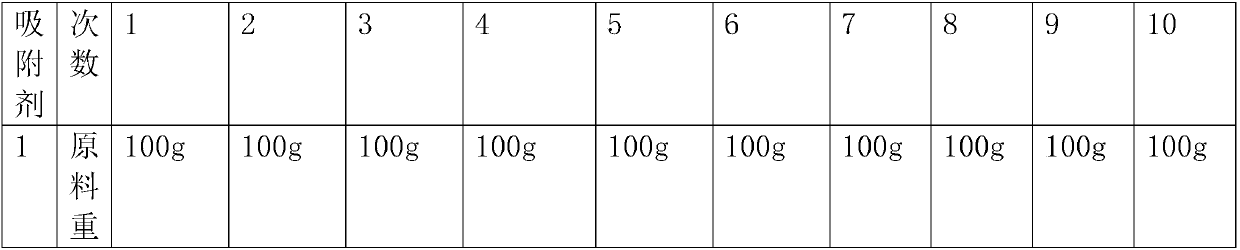

Embodiment 1

[0032] Weigh 100g of LX68M resin, put it in a 500ml beaker, measure 100ml of absolute ethanol, add it to the resin, stir for 10 minutes, and place it for 2 hours.

[0033] The resin was filtered and the ethanol was discarded. Put the resin in a 1000ml beaker, add 100ml of purified water, stir for 10 minutes, let stand for 1 hour, filter, and discard the water. According to the above steps, wash the resin twice with 100ml and 100ml of water respectively, filter, discard the water, and reserve the resin for later use.

[0034] The washed resin was placed in a 500ml beaker, 100ml of 5% hydrochloric acid solution was measured, added to the resin, stirred for 10 minutes, and left for 3 hours. Filter and discard the hydrochloric acid solution. Resin spare.

[0035] Weigh 5 g of barium chloride, 2 g of strontium sulfate, 10 g of ferrous chloride, 2 g of rubidium oxide, and 1 g of zirconium oxide. Place in a 500ml beaker and stir to mix.

[0036] Measure 100ml of 5% hydrochloric ...

Embodiment 2

[0040] Weigh 100g of LX68M resin, put it in a 500ml beaker, measure 200ml of absolute ethanol, add it to the resin, stir for 10 minutes, and place it for 2 hours.

[0041] The resin was filtered and the ethanol was discarded. Put the resin in a 1000ml beaker, add 100ml of purified water, stir for 10 minutes, let stand for 1 hour, filter, and discard the water. According to the above steps, wash the resin twice with 100ml and 100ml of water respectively, filter, discard the water, and reserve the resin for later use.

[0042] The washed resin was placed in a 500ml beaker, 150ml of 5% hydrochloric acid solution was measured, added to the resin, stirred for 10 minutes, and left for 1 hour. Filter and discard the hydrochloric acid solution. Resin spare.

[0043] Weigh 10 g of barium chloride, 4 g of strontium sulfate, 20 g of ferrous chloride, 4 g of rubidium oxide, and 2 g of zirconium oxide. Place in a 500ml beaker and stir to mix.

[0044] Measure 100ml of 5% hydrochloric ...

Embodiment 3

[0048] Weigh 100g of LX68M resin, put it in a 500ml beaker, measure 100ml of absolute ethanol, add it to the resin, stir for 10 minutes, and place it for 2 hours.

[0049] The resin was filtered and the ethanol was discarded. Put the resin in a 1000ml beaker, add 100ml of purified water, stir for 10 minutes, let stand for 1 hour, filter, and discard the water. The resin was washed once with 100 ml of water according to the above steps, filtered, and the water was discarded, and the resin was set aside.

[0050] The washed resin was placed in a 500ml beaker, 150ml of 5% hydrochloric acid solution was measured, added to the resin, stirred for 10 minutes, and left for 2 hours. Filter and discard the hydrochloric acid solution. Resin spare.

[0051] Weigh 20 g of barium chloride, 8 g of strontium sulfate, 40 g of ferrous chloride, 8 g of rubidium oxide, and 4 g of zirconium oxide. Place in a 500ml beaker and stir to mix.

[0052] Measure 100ml of 5% hydrochloric acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com