A preparation device for colored rubber and plastic thermal insulation materials

A technology for heat insulation materials and preparation devices, which is applied in the field of preparation devices for colored rubber and plastic heat insulation materials, and can solve the problems of inability to stabilize the internal structure of colored rubber and plastic heat insulation materials, uniform foaming of colored rubber and plastic heat preservation materials, and failure to meet the requirements for closed cell ratio, etc. problems, to achieve the effect of high tear strength, strong water vapor permeability, not easy to shrink and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

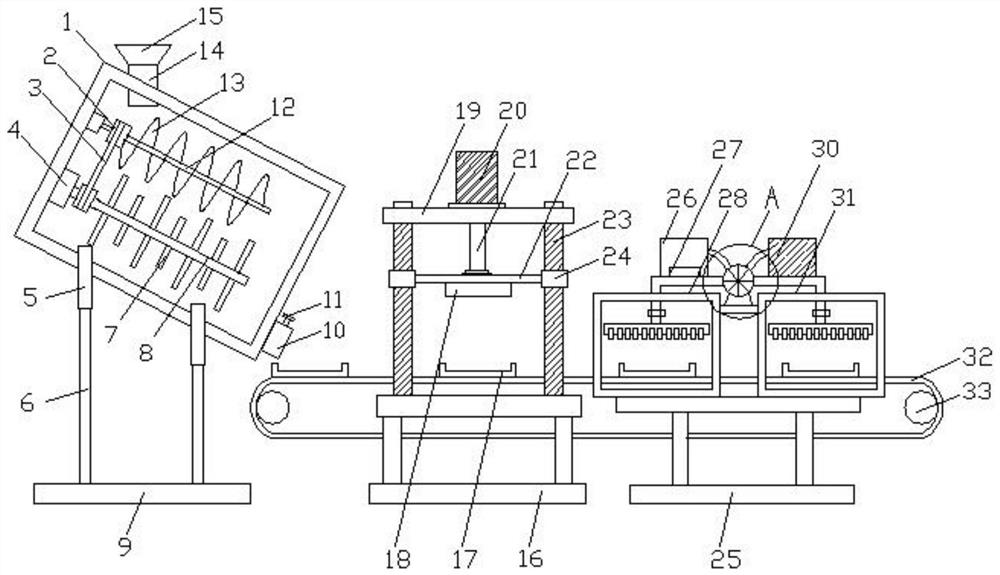

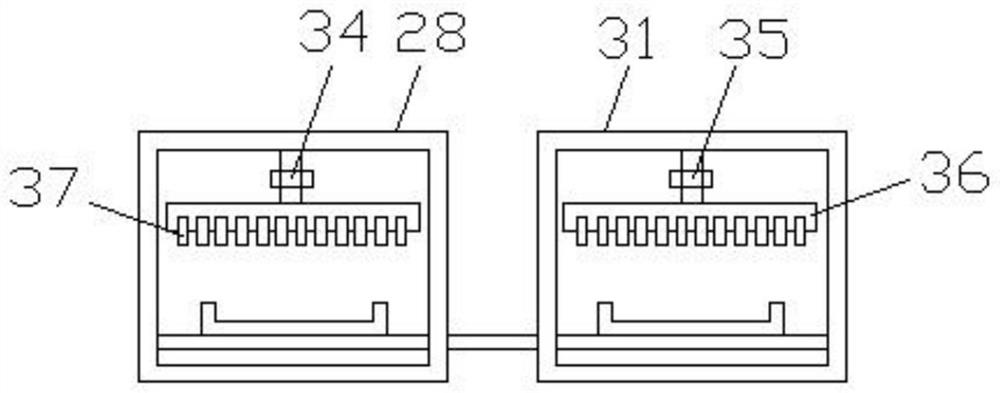

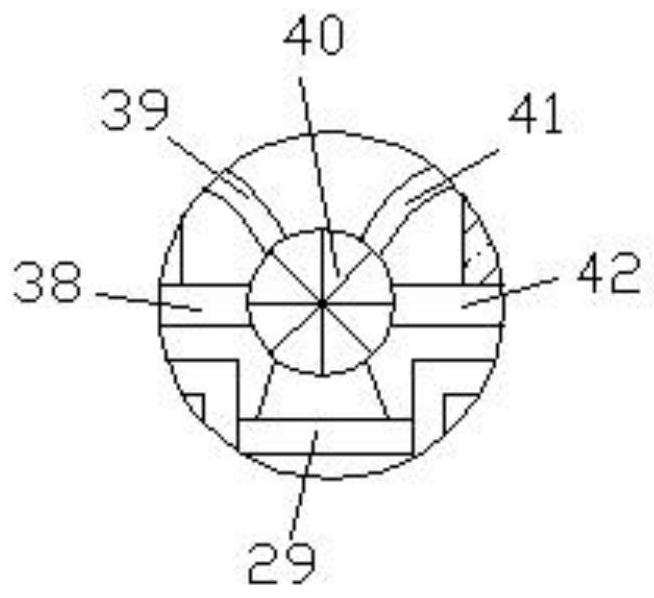

[0024] see Figure 1-3 According to an embodiment of the present invention, a colored rubber and plastic thermal insulation material preparation device includes a stirring device 1, a first workbench 16 and a second workbench 25, a stirring motor 4 is installed on one side of the stirring device 1, and the The stirring motor 4 is provided with a first stirring shaft 8, the first stirring shaft 8 is provided with a stirring rod 7, the stirring rod 7 is a plurality, and a second stirring shaft 8 is installed on one side of the first stirring shaft 8. Shaft 12, the first stirring shaft 8 and the second stirring shaft 12 are equipped with a pulley 2, the pulley 2 is provided with a flat belt 3, and the second stirring shaft 12 is equipped with a spiral stirring paddle 13, so A discharge port 10 is left on one side of the bottom of the stirring device 1, a valve 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com