Electric automobile optimization scheduling method based on alternating direction multiplier method

A technology of alternating direction multipliers and electric vehicles, applied in electric vehicles, electric vehicle charging technology, charging stations, etc., can solve the problem of affecting the voltage level of the distribution network, adverse to the development of the distribution network, affecting the battery cycle life, electrode side reactions, etc. performance and other issues, to avoid voltage drops and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will now be described in further detail in conjunction with the accompanying drawings, and the specific embodiments are as follows.

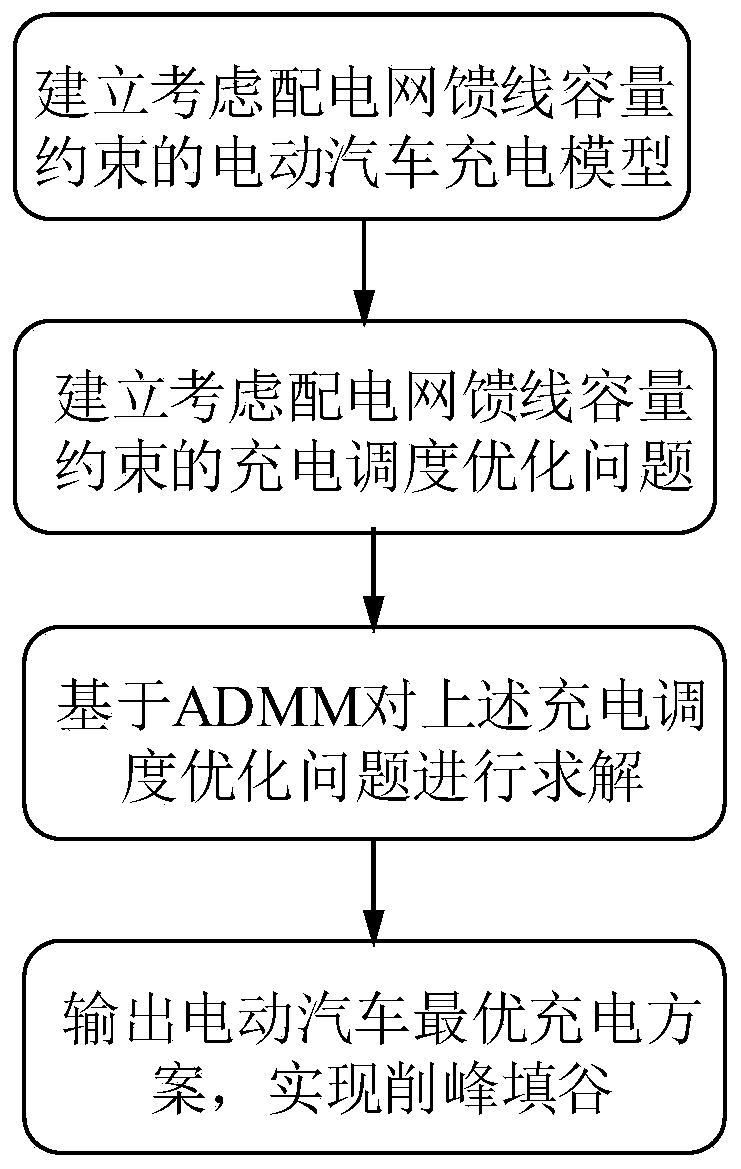

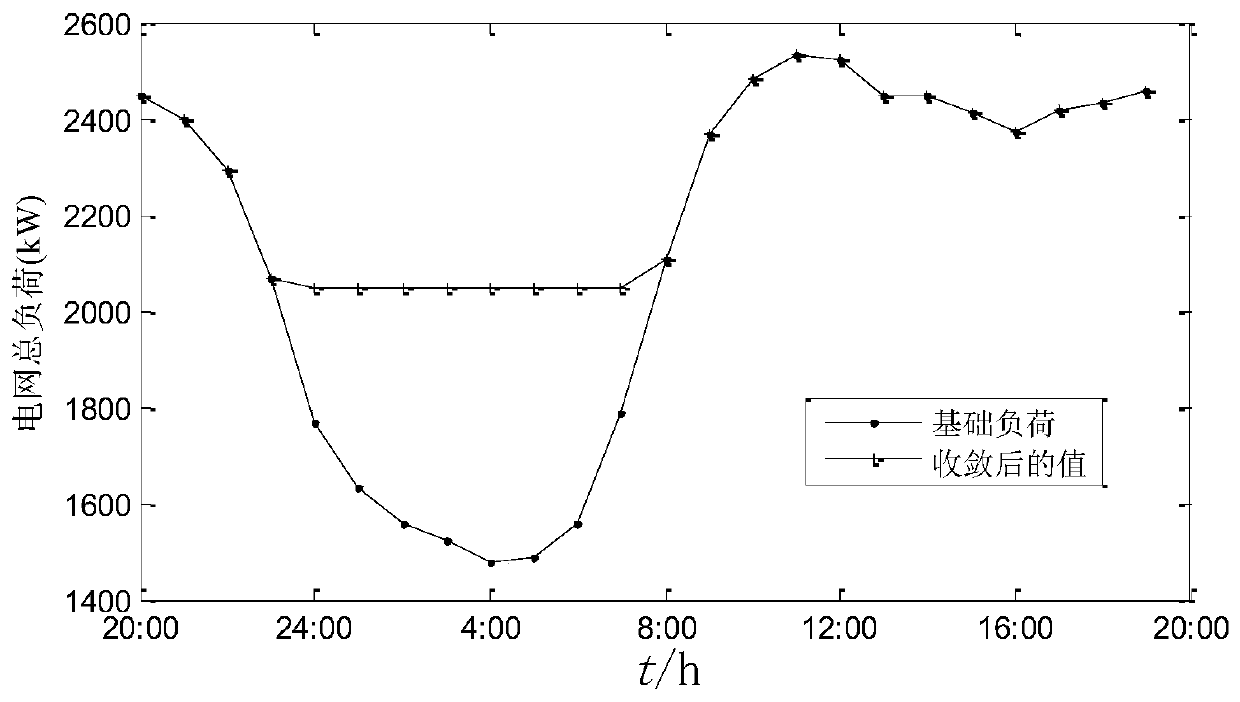

[0067] In order to verify the feasibility of the method, a distribution network system with 4 feeders is selected for illustration. like figure 1 As shown, the electric vehicle optimal scheduling method based on the alternating direction multiplier method disclosed in this embodiment, the specific implementation steps are as follows:

[0068] Step 1: Establish an electric vehicle charging model considering the capacity constraints of distribution network feeders;

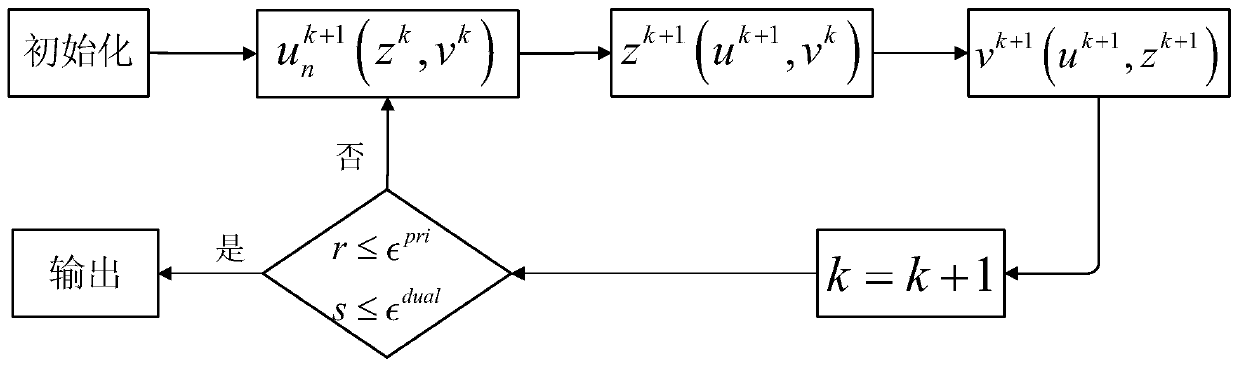

[0069] Define the set of electric vehicles as use and Respectively represent the collection of feeders and nodes in the distribution network, the nodes mentioned are except the root node, use and denote the set of EVs connected to node m and feeder l, respectively. Define a matrix A≡[a lm ] L×M ,in and is the cardinality of the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com