Cold-resistant flame-retardant covering glue, cold-resistant flame-retardant middle glue, cold-resistant flame-retardant core glue and cold-resistant flame-retardant steel wire core conveyor belt

A technology of steel wire rope core and covering rubber, applied in the field of conveyor belts, can solve the problems of reducing the elasticity and troughing of conveyor belts, reducing the bonding force between steel wire ropes and rubber, cracking, etc., achieving good cold resistance and flame retardant properties, ensuring flame retardant properties Good performance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

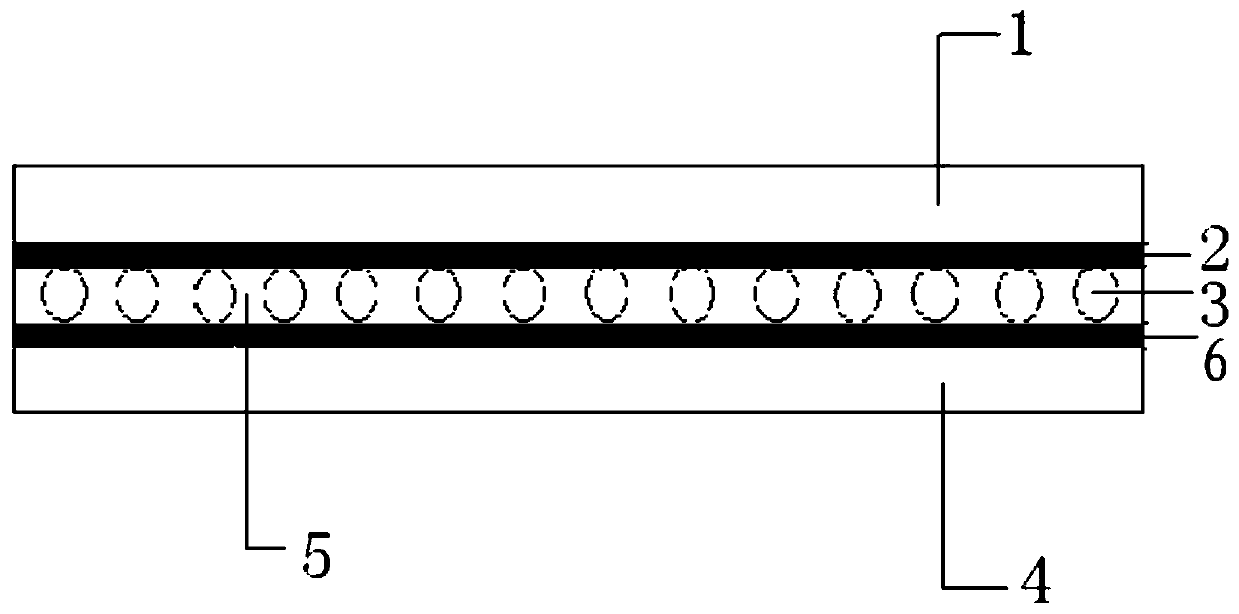

Image

Examples

Embodiment 1

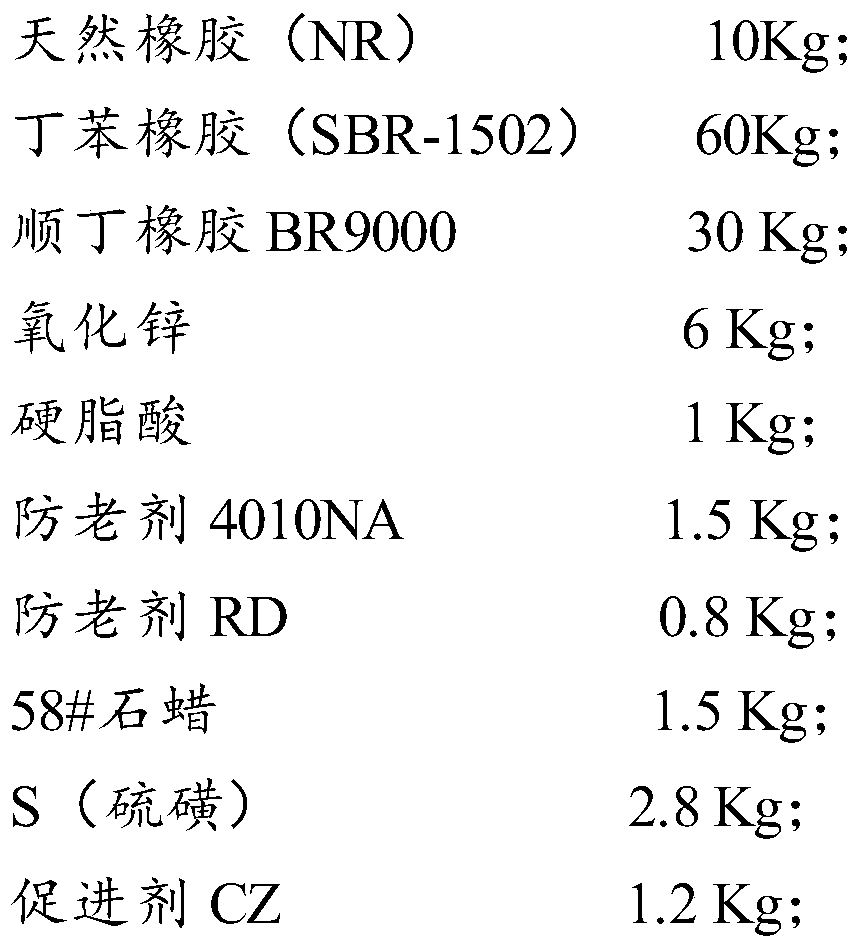

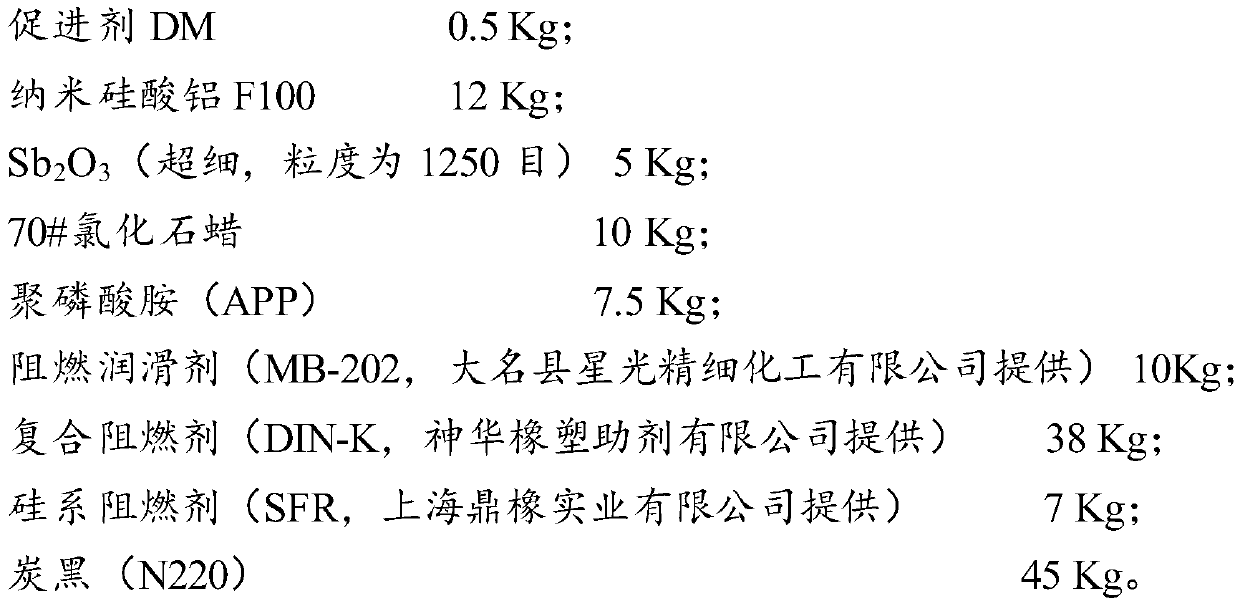

[0133] The composition of the cold-resistant and flame-retardant cover glue is:

[0134]

[0135]

[0136] The composition of the cold-resistant and flame-retardant intermediate rubber is:

[0137]

[0138]

[0139] According to the composition of the cold-resistant and flame-retardant covering rubber, add natural rubber, styrene-butadiene rubber and butadiene rubber first, then add zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, 58# paraffin, accelerator CZ, accelerator DM, and then Add nano aluminum silicate F100, Sb 2 o 3 , 70# chlorinated paraffin, amine polyphosphate (APP), flame retardant lubricant (MB-202, provided by Daming Xingguang Fine Chemical Co., Ltd.), composite flame retardant (DIN-K, provided by Shenhua Rubber and Plastic Additives Co., Ltd. ), silicon-based flame retardant (SFR, provided by Shanghai Ding Rubber Industrial Co., Ltd.) and carbon black (N220), and finally add S (sulfur) for rough refining: the temperature of...

Embodiment 2

[0146] The composition of the cold-resistant and flame-retardant cover glue is:

[0147]

[0148] The composition of the cold-resistant and flame-retardant intermediate rubber is:

[0149]

[0150]

[0151] The composition of the cold-resistant and flame-retardant core rubber is:

[0152]

[0153]

[0154] Add styrene-butadiene rubber and butadiene rubber according to the composition of the cold-resistant and flame-retardant covering rubber, then add zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, 58# paraffin, accelerator CZ, accelerator DM, and then add nano-silicon Aluminum acid F100, Sb 2 o 3 , 70# chlorinated paraffin, amine polyphosphate (APP), flame retardant lubricant (MB-202, provided by Daming Xingguang Fine Chemical Co., Ltd.), composite flame retardant (DIN-K, provided by Shenhua Rubber and Plastic Additives Co., Ltd. ), silicon-based flame retardant (SFR, provided by Shanghai Ding Rubber Industrial Co., Ltd.) and carbon bl...

Embodiment 3

[0161] The composition of the cold-resistant and flame-retardant cover glue is:

[0162]

[0163]

[0164] The composition of the cold-resistant and flame-retardant intermediate rubber is:

[0165]

[0166] The composition of the cold-resistant and flame-retardant core rubber is:

[0167]

[0168]

[0169] According to the composition of the cold-resistant and flame-retardant covering rubber, add natural rubber, styrene-butadiene rubber and butadiene rubber first, then add zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, 58# paraffin, accelerator CZ, accelerator DM, and then Add nano aluminum silicate F100, Sb 2 o 3 , 70# chlorinated paraffin, amine polyphosphate (APP), flame retardant lubricant (MB-202, provided by Daming Xingguang Fine Chemical Co., Ltd.), composite flame retardant (DIN-K, provided by Shenhua Rubber and Plastic Additives Co., Ltd. ), silicon-based flame retardant (SFR, provided by Shanghai Ding Rubber Industrial Co., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com