Ceramic PVC material and preparation method

A PVC material, ceramic technology, applied in the field of plastic processing, can solve the problems of accelerated combustion, lack of mechanical strength of materials, short circuit of wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

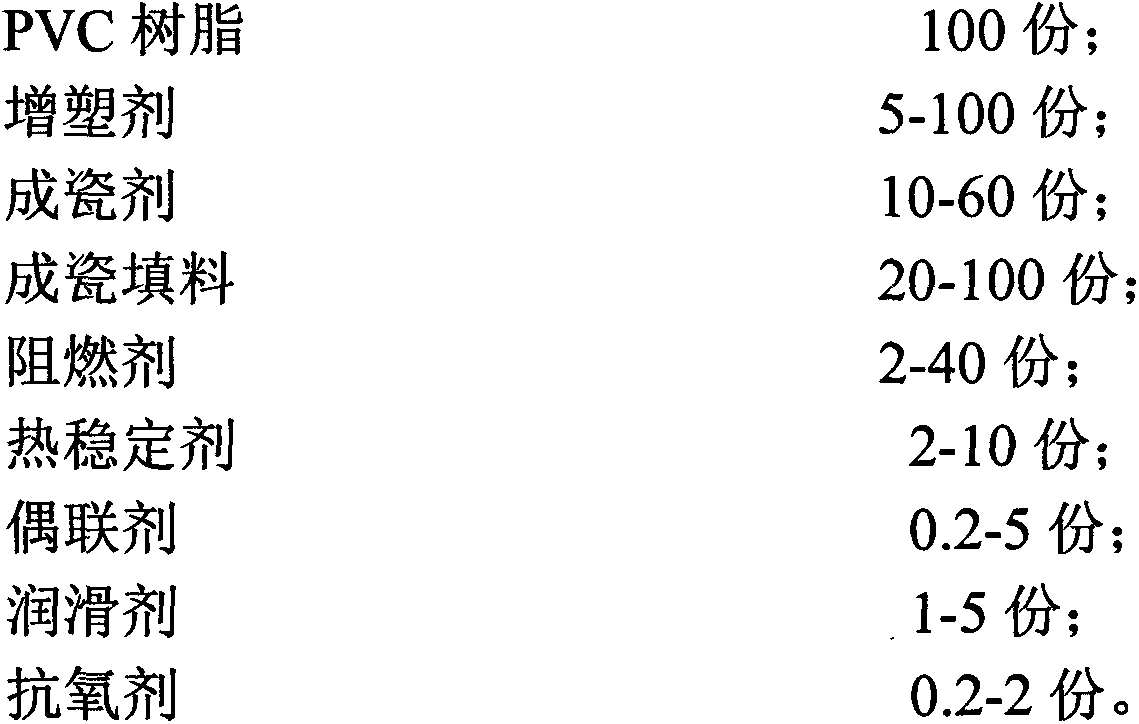

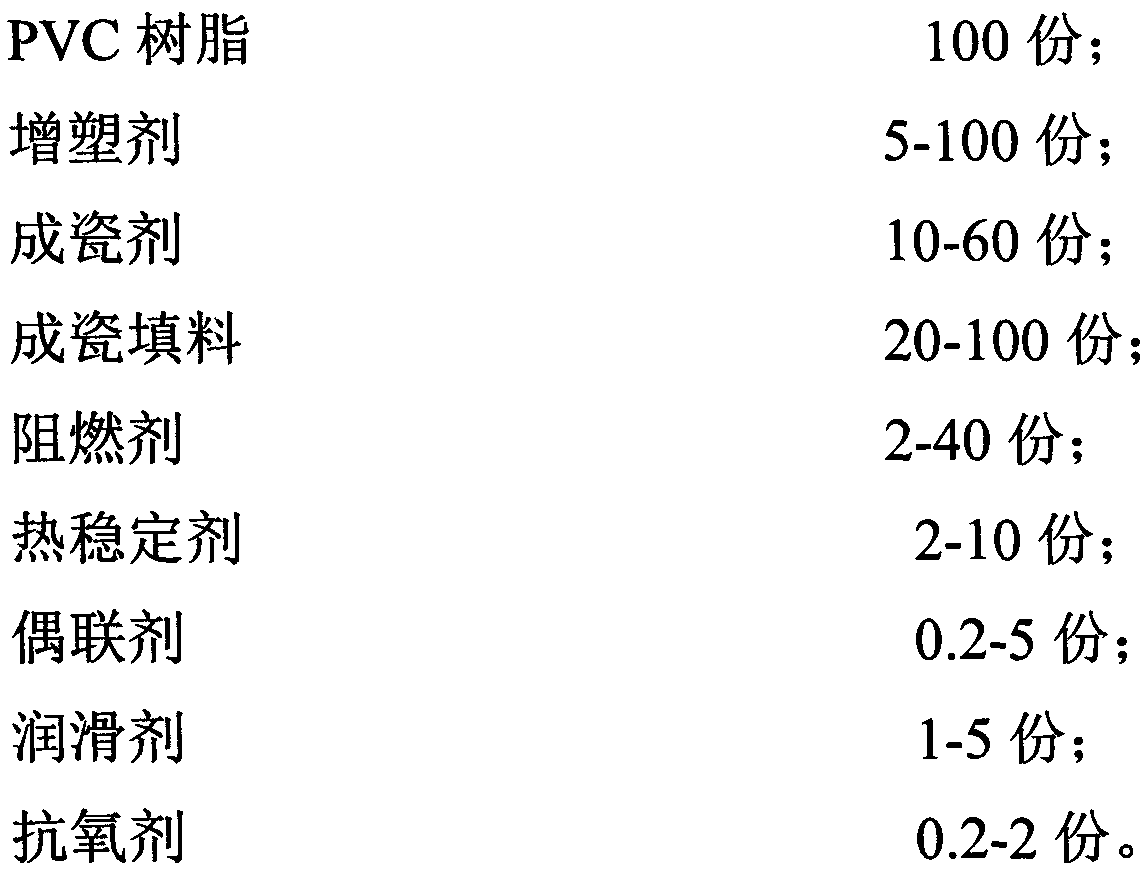

Method used

Image

Examples

Embodiment 1

[0019] The preparation of ceramic flame-retardant PVC material includes the following steps:

[0020] (1) Surface coupling modification treatment: Combine 10 parts of porcelain-forming agent calcium borate, 12 parts of zinc borate, 14 parts of porcelain-forming filler calcined clay and 12 parts of mica powder at a temperature of 65-70℃ and a rotation speed of 700-800r / min Mix for 1-5 minutes in a high-speed mixer, add dropwise about 3 parts of silane coupling agent KH550, continue to mix for 3-8 minutes, then take it out for use; (2) Combine 100 parts of PVC resin, 5 parts of antimony trioxide, flame retardant, 10 parts of triphenyl phosphate (TPP), 3 parts of heat stabilizer tribasic lead sulfate, 4 parts of di-salt lead phosphite, 1 part of lubricant stearic acid, 1.5 parts of zinc stearate, 1010 of antioxidant, about 0.3 1 part of antioxidant 264 and about 51 parts of the porcelain-forming agent and porcelain-forming filler that have been coupled and modified in the previous s...

Embodiment 2

[0022] The preparation of ceramic flame-retardant PVC material includes the following steps:

[0023] (1) Surface coupling modification treatment; combine 12 parts of low melting point glass powder, 12 parts of borax, 21 parts of wollastonite powder and 3 parts of barium sulfate at a temperature of 65-75℃ and a rotation speed of 500-600r Mix in a high-speed mixer for 3-5 minutes, add dropwise about 2.5 parts of silane coupling agent KH570, continue to mix for 6-8 minutes, then take it out for use; (2) Combine 100 parts of PVC resin, flame retardant ammonium polyphosphate (APP ) 6 parts, melamine cyanurate (MCA) 9 parts, heat stabilizer calcium zinc composite stabilizer 7 parts, lubricant calcium stearate 1.5 parts, barium stearate 1 part, antioxidant 1076 about 0.3 parts, About 1 part of antioxidant CA and about 50.5 parts of the porcelain-forming agent and porcelain-forming filler that have been coupled and modified in the previous step are put into the kneader, kneaded at 65-80...

Embodiment 3

[0025] The preparation of ceramic flame-retardant PVC material includes the following steps:

[0026] (1) Surface coupling modification treatment: Combine 12 parts of porcelain-forming agent low melting point glass powder, 12 parts of calcium borate, 22 parts of porcelain-forming filler kaolin powder, and 4 parts of mica powder at a temperature of 75-80℃ and a rotation speed of 500-600r / min high-speed mixer for 5 minutes, add dropwise about 2.5 parts of silane coupling agent A151, continue to mix for 8 minutes and then take out for use; (2) 100 parts of PVC resin, 5 parts of flame retardant triphenyl phosphate (TPP) , 10 parts of ammonium polyphosphate (APP), 3 parts of heat stabilizer di-salt lead phosphite, 4 parts of calcium-zinc composite stabilizer, 1 part of lubricant oleic acid amide, 1.5 parts of erucamide, and about 0.3 parts of antioxidant 1010 、About 1 part of antioxidant CA and about 52.5 parts of porcelain-forming agent and porcelain-forming filler that have been co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com