Environmentally friendly soluble ink and preparing process thereof

A soluble and environmentally friendly technology, used in inks, household appliances, applications, etc., can solve the problems of inhibiting the development and application of soluble inks, poor weather resistance, slow drying speed, etc., to improve hydrophilicity and stability, and enhance solubility. , the effect of polarity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

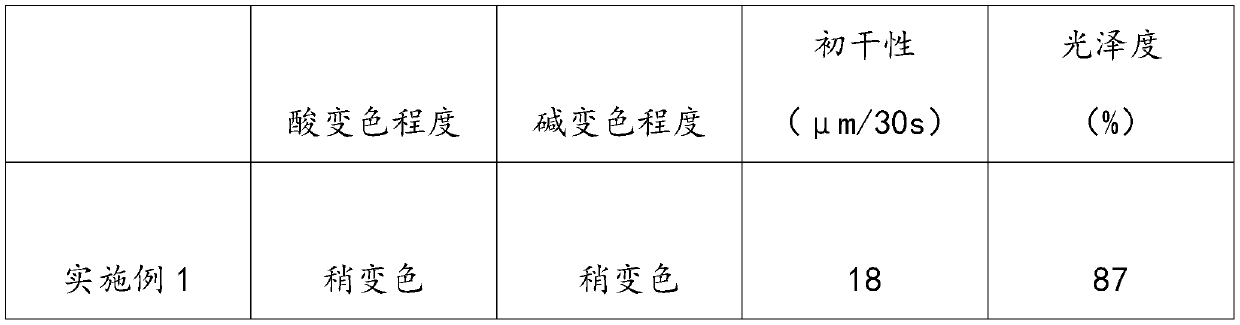

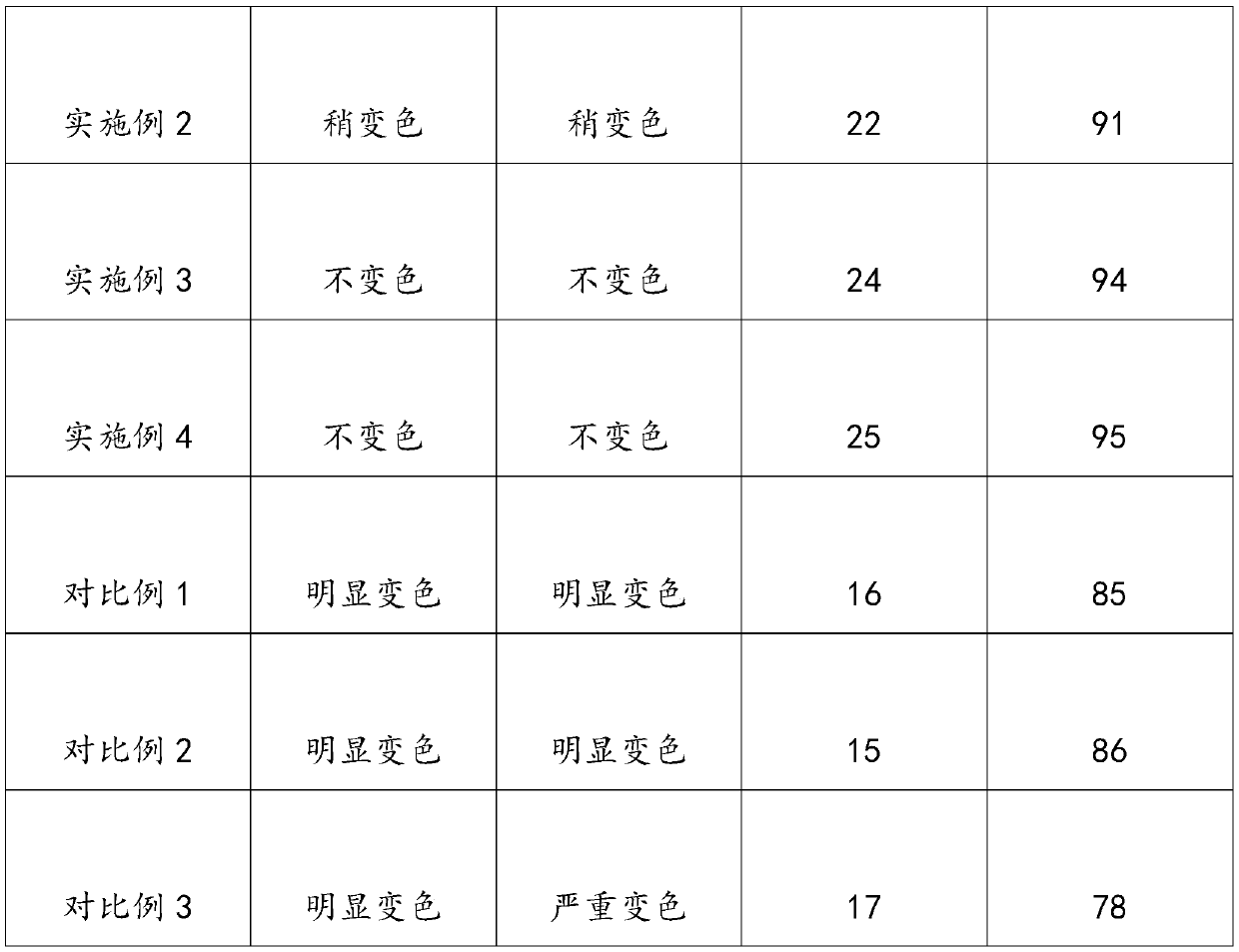

Examples

Embodiment 1

[0039] Environmentally friendly soluble ink, made of the following raw materials by weight: 55 parts of modified acrylic resin, 40 parts of environmentally friendly pigments and fillers, 70 parts of n-butanol, 55 parts of absolute ethanol, 15 parts of HPMA, 15 parts of polyvinylpyrrolidone, 35 parts of overspend Polyglycerol, 5 parts of polyoxypropylene glyceryl ether;

[0040] Described environment-friendly soluble ink is made by following steps:

[0041] Step S1, add the modified acrylic resin into a beaker filled with n-butanol, heat in a water bath at 45°C, stir at a constant speed for 15 minutes, then add hyperbranched polyglycerol, raise the temperature to 60°C, stir for 5 minutes, and prepare as liquid A for later use;

[0042] Step S2. Add absolute ethanol and HPMA into a three-necked flask, heat in a water bath at 60°C, stir magnetically for 30 minutes, add polyoxypropylene glyceryl ether, heat up to 75°C after polyoxypropylene glyceryl ether dissolves, add polyvinylp...

Embodiment 2

[0056] Environmentally friendly soluble ink, made of the following raw materials in parts by weight: 60 parts of modified acrylic resin, 42 parts of environmentally friendly pigments and fillers, 80 parts of n-butanol, 60 parts of absolute ethanol, 18 parts of HPMA, 16 parts of polyvinylpyrrolidone, 40 parts of overrun Polyglycerol, 8 parts of polyoxypropylene glyceryl ether;

[0057] Described environment-friendly soluble ink is made by following steps:

[0058] Step S1, add the modified acrylic resin into a beaker filled with n-butanol, heat in a water bath at 45°C, stir at a constant speed for 15 minutes, then add hyperbranched polyglycerol, raise the temperature to 60°C, stir for 5 minutes, and prepare as liquid A for later use;

[0059] Step S2. Add absolute ethanol and HPMA into a three-necked flask, heat in a water bath at 60°C, stir magnetically for 30 minutes, add polyoxypropylene glyceryl ether, heat up to 75°C after polyoxypropylene glyceryl ether dissolves, add pol...

Embodiment 3

[0064] Environmentally friendly soluble ink, made of the following raw materials by weight: 70 parts of modified acrylic resin, 50 parts of environmentally friendly pigments and fillers, 90 parts of n-butanol, 70 parts of absolute ethanol, 22 parts of HPMA, 18 parts of polyvinylpyrrolidone, 46 parts of overrun Polyglycerol, 12 parts of polyoxypropylene glyceryl ether;

[0065] Described environment-friendly soluble ink is made by following steps:

[0066] Step S1, add the modified acrylic resin into a beaker filled with n-butanol, heat in a water bath at 45°C, stir at a constant speed for 15 minutes, then add hyperbranched polyglycerol, raise the temperature to 60°C, stir for 5 minutes, and prepare as liquid A for later use;

[0067] Step S2. Add absolute ethanol and HPMA into a three-necked flask, heat in a water bath at 60°C, stir magnetically for 30 minutes, add polyoxypropylene glyceryl ether, heat up to 75°C after polyoxypropylene glyceryl ether dissolves, add polyvinylpy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com