Environment-friendly coal transportation antifreezing agent and preparation method thereof

An antifreeze and environment-friendly technology, which is applied in the field of environment-friendly antifreeze for coal transportation and its preparation, can solve the problems of excessive chlorine content in commercial coal and affect export earnings, etc., and achieve the effects of preventing trains from freezing coal, convenient transportation, and safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

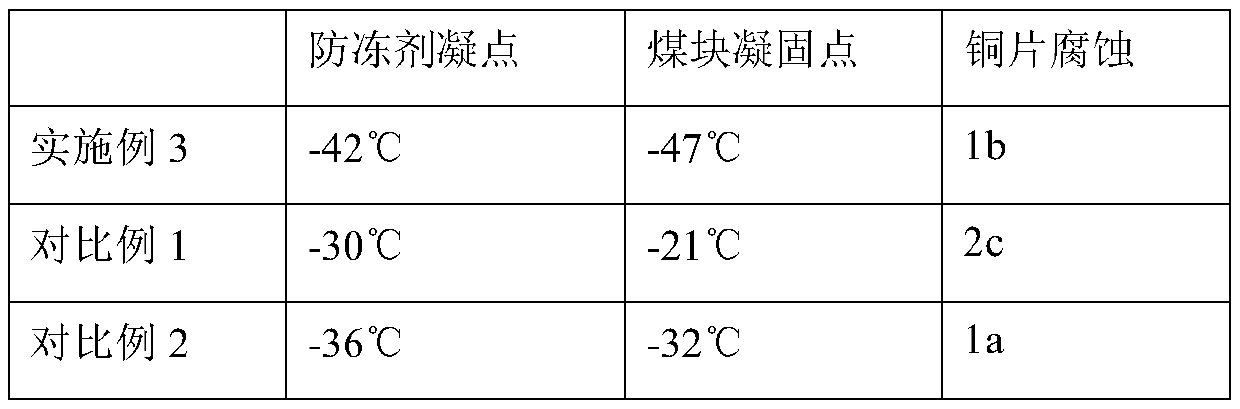

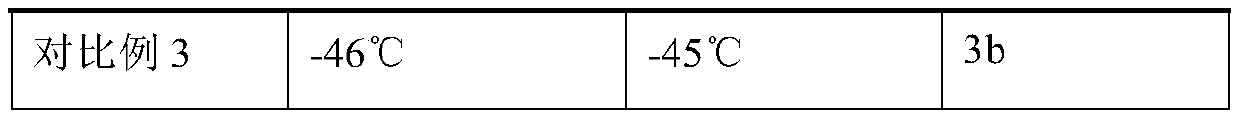

Examples

Embodiment 1

[0023] The environment-friendly antifreeze agent for coal transportation described in this embodiment comprises the following components by weight: 18 parts of potassium acetate, 9 parts of sodium formate, 12 parts of urea, 6 parts of ethylene glycol, 0.5 part of glycerol, 2 parts of sodium benzoate, benzene And triazole 0.06 parts, water 53 parts.

[0024] The environment-friendly antifreeze agent for coal transportation described in this embodiment is prepared according to the following method:

[0025] (1) Take the above-mentioned selected amount of water, potassium acetate, sodium formate, urea, benzotriazole, and sodium benzoate and add them to the reaction kettle for mixing, control the temperature of the reaction system to rise to 60°C and stir for 4 hours until completely dissolved;

[0026] (2) Then add the selected amount of ethylene glycol and glycerol into the reaction kettle in turn, mix and stir until the materials are completely dissolved, then cool down to 10-3...

Embodiment 2

[0028] The environment-friendly antifreeze agent for coal transportation described in this embodiment comprises the following components by weight: 7 parts of potassium acetate, 14 parts of sodium formate, 11 parts of urea, 4 parts of ethylene glycol, 1.0 part of glycerol, 2 parts of sodium benzoate, benzene 0.1 part of triazole and 61 parts of water.

[0029] The environment-friendly antifreeze agent for coal transportation described in this embodiment is prepared according to the following method:

[0030] (1) Take the above-mentioned selected amount of water, potassium acetate, sodium formate, urea, benzotriazole, and sodium benzoate and add them to the reaction kettle for mixing, control the temperature of the reaction system to 80°C and stir for 1 hour until completely dissolved;

[0031] (2) Then add the selected amount of ethylene glycol and glycerol into the reaction kettle in turn, mix and stir until the materials are completely dissolved, then cool down to 10-35°C, a...

Embodiment 3

[0033] The environment-friendly antifreeze agent for coal transportation described in this embodiment comprises the following components by weight: 11 parts of potassium acetate, 12 parts of sodium formate, 10.5 parts of urea, 4 parts of ethylene glycol, 1.0 part of glycerol, 1.5 parts of sodium benzoate, benzene And triazole 0.08 parts, water 60 parts.

[0034] The environment-friendly antifreeze agent for coal transportation described in this embodiment is prepared according to the following method:

[0035] (1) Take the above-mentioned selected amount of water, potassium acetate, sodium formate, urea, benzotriazole, and sodium benzoate and add them to the reaction kettle for mixing, control the temperature of the reaction system to 75°C and stir for 2 hours until completely dissolved;

[0036] (2) Then add the selected amount of ethylene glycol and glycerol into the reaction kettle in turn, mix and stir until the materials are completely dissolved, then cool down to 25°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com