Method for preparing full-inorganic perovskite quantum dots with high fluorescence quantum yield

A technology of fluorescence quantum yield and inorganic calcium, which is applied in the field of preparation of perovskite quantum dots, can solve the problems of inability to meet the application of optoelectronic functional materials, and achieve the effects of simple preparation method, good stability and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

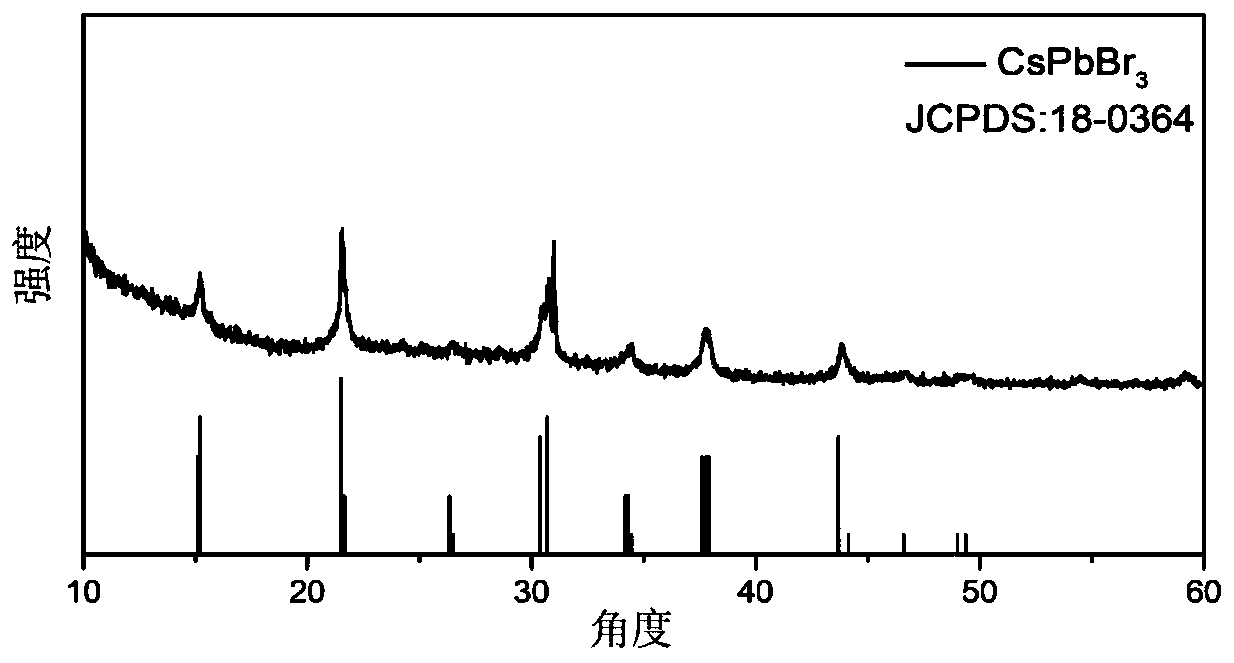

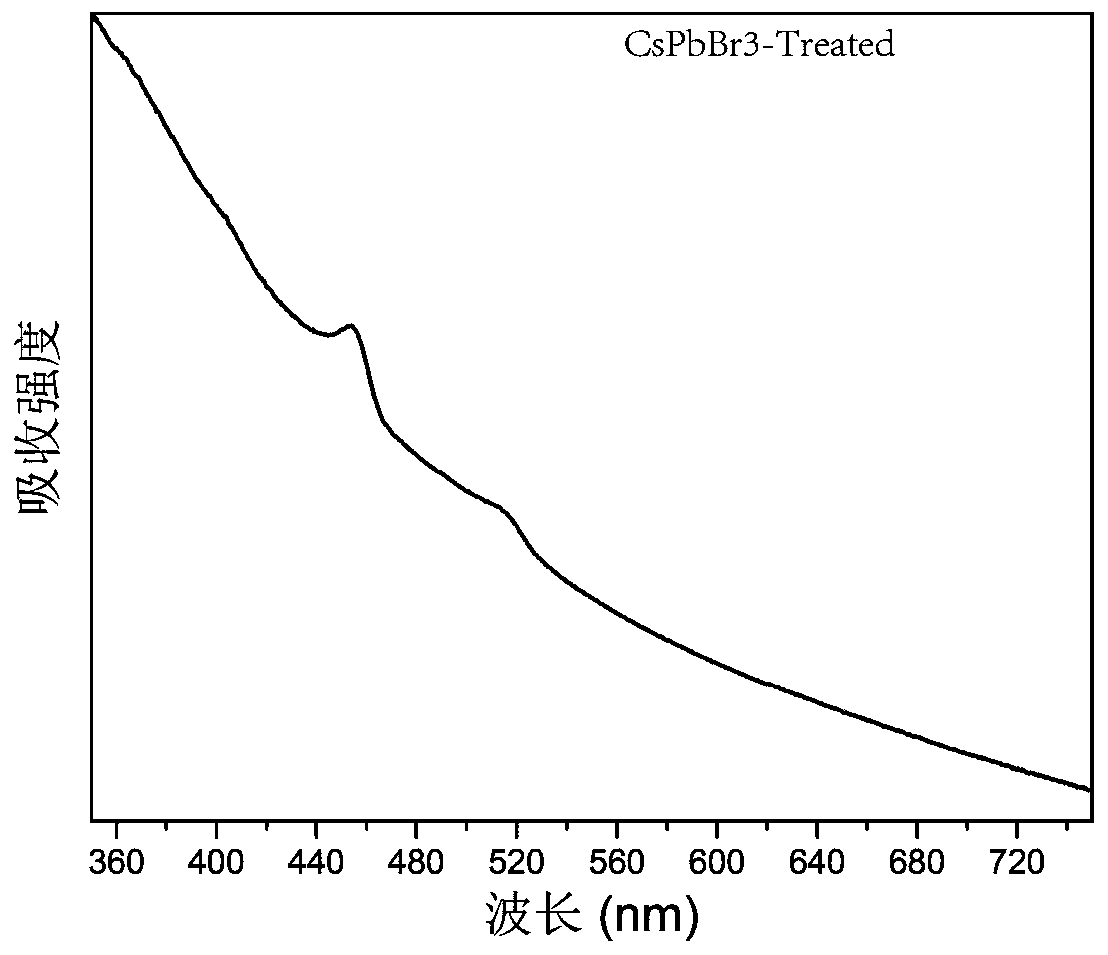

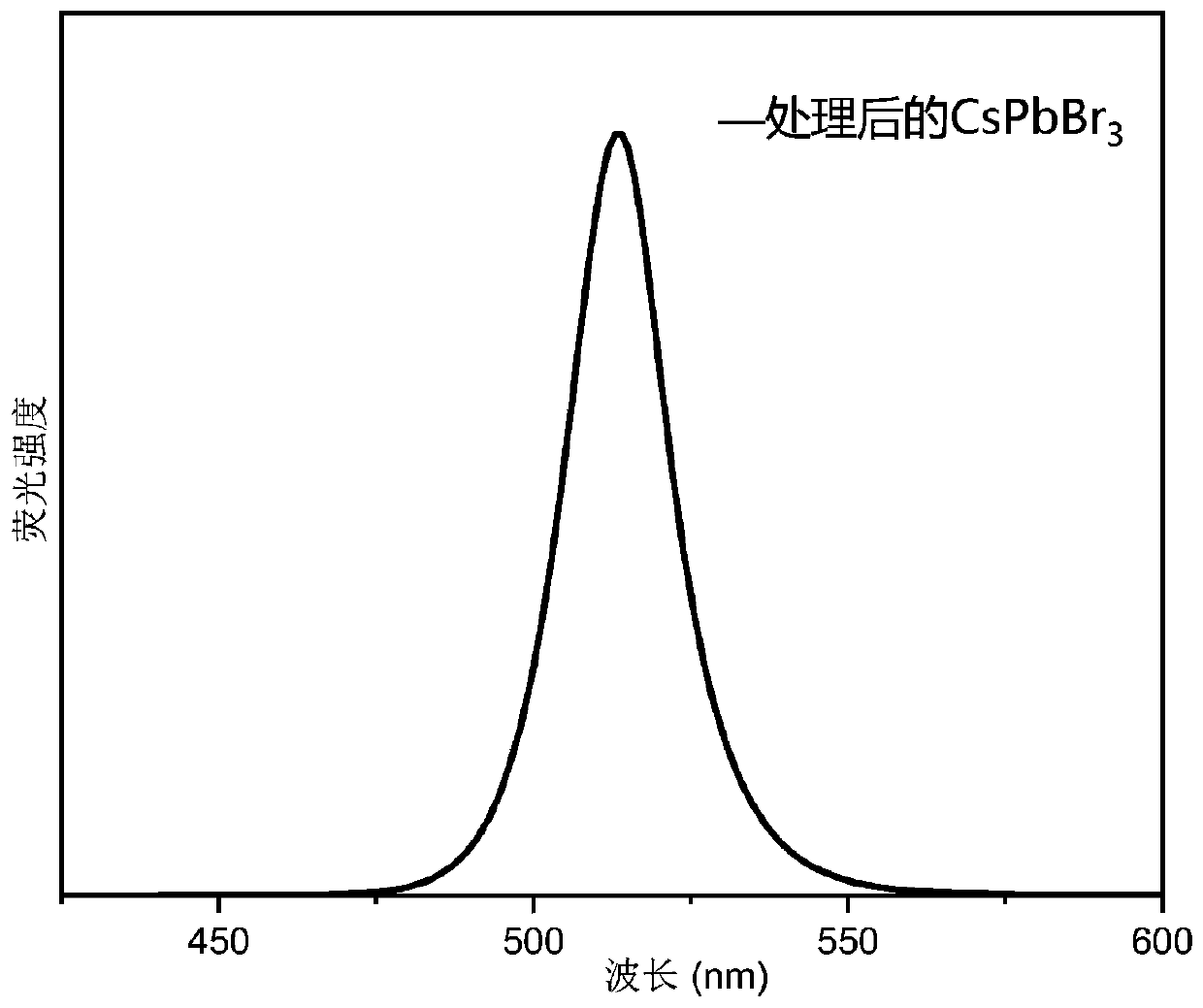

[0017] Embodiment 1: use KBr solution to CsPbBr 3 The preparation method for post-processing is as follows:

[0018] (1) Add 5 mL of octadecene (ODE), 313 μL of oleic acid (OA), 0.101 g of cesium carbonate (CsCO 3 ), heated to 120°C and vacuumed for 30min, N 2 Stir at 150°C under atmosphere until the solution becomes clear;

[0019] (2) In a 25mL three-necked flask, add 20mL of octadecene (ODE), 2mL of oleylamine (OAm), 2mL of oleic acid (OA), 0.276g of lead bromide (PbBr 2 ), heated to 120°C, vacuumed for 30 minutes, and then passed nitrogen for 10 minutes, repeated three times, and the temperature was raised to 160°C when passing nitrogen for the last time;

[0020] (3) Take 1.6 mL of Cs-oil in step (1), quickly inject it into the system of step (2), react for 5 seconds, and immediately put it into an ice-water bath;

[0021] (4) Take 5mL of the solution after the reaction in step (3), centrifuge at 11000r / min for 5min, discard the supernatant, add 5mL of n-hexane, centr...

Embodiment 2

[0024] Example 2: Using CdBr 2 solution to CsPbBr 3 The preparation method for post-processing is as follows:

[0025] (1) Add 5 mL of octadecene (ODE), 313 μL of oleic acid (OA), 0.101 g of cesium carbonate (CsCO 3 ), heated to 120°C and vacuumed for 30 minutes, stirred at 150°C under a helium atmosphere until the solution became clear;

[0026] (2) In a 25mL three-necked flask, add 20mL of octadecene (ODE), 2mL of oleylamine (OAm), 2mL of oleic acid (OA), 0.276g of lead bromide (PbBr 2 ), heated to 120°C, vacuumed for 30 minutes, and then passed nitrogen for 10 minutes, repeated three times, and the temperature was raised to 160°C when passing nitrogen for the last time;

[0027] (3) Take 1.6 mL of Cs-oil in step (1), quickly inject it into the system of step (2), react for 5 seconds, and immediately put it into an ice-water bath;

[0028] (4) Take 5mL of the solution after the reaction in step (3), centrifuge at 11000r / min for 5min, discard the supernatant, add 5mL of n...

Embodiment 3

[0031] Embodiment 3: use the cadmium bromide solution of different concentrations to CsPbBr 3 The preparation method for post-processing is as follows:

[0032] (1) Add 5 mL of octadecene (ODE), 313 μL of oleic acid (OA), 0.101 g of cesium carbonate (CsCO 3 ), heated to 120°C and vacuumed for 30min, N 2 Stir at 150°C under atmosphere until the solution becomes clear;

[0033] (2) In a 25mL three-necked flask, add 20mL of octadecene (ODE), 2mL of oleylamine (OAm), 2mL of oleic acid (OA), 0.276g of lead bromide (PbBr 2 ), heated to 120°C, vacuumed for 30 minutes, and then passed nitrogen for 10 minutes, repeated three times, and the temperature was raised to 160°C when passing nitrogen for the last time;

[0034] (3) Take 1.6 mL of Cs-oil in step (1), quickly inject it into the system of step (2), react for 5 seconds, and immediately put it into an ice-water bath;

[0035] (4) Take 5mL of the solution after the reaction in step (3), centrifuge at 11000r / min for 5min, discard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com