Preparing method of proteolytic peptides extracted from debitterized peach kernels

A proteolysis and peach kernel technology, applied in the field of plant protein extraction and processing, can solve the problems of unacceptable to consumers, reduction of proteolytic peptides, and incomplete elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pressing and deoiling: Peeled peach kernels are peeled and crushed through a 10-mesh sieve, then steamed and fried for 15 minutes at a temperature of 85°C, and then cold-pressed with a double-screw oil press at a temperature of 50°C. Afterwards, the peach kernel cake is obtained;

[0032](2) Protein extraction: crush the peach kernel cake obtained in step (1) through a 100-mesh sieve, then mix it with pure water at a material-to-liquid ratio of 1:18 to form a suspension, adjust its pH to 11, and place it magnetically at 45°C Stir for 95min; then place the suspension at a speed of 12000r / min and centrifuge for 15 minutes to obtain a supernatant; adjust the pH of the supernatant to 5.5 and then centrifuge at a speed of 12000r / min for 15min to obtain a precipitate, which is then freeze-dried. get peach kernel extract protein powder;

[0033] (3) Proteolysis: add the peach kernel protein powder obtained in step (2) to deionized water to prepare a 5% peach kernel protei...

Embodiment 2

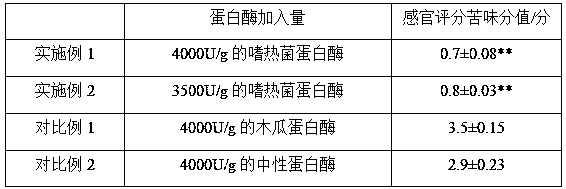

[0043] The only difference between this example and Example 1 is that the amount of thermolysin added in step (3) is 3500 U / g, and the average score of the protein hydrolyzed polypeptide component of the peach kernel extract according to the sensory score described in the above example The results are shown in Table 1.

Embodiment 3

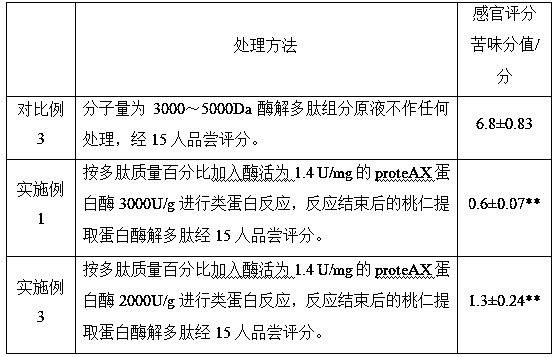

[0045] The difference between this example and Example 1 is that the amount of proteAX protease mentioned in step (5) is 2000U / g. See Table 2 for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com