On-line monitoring device for fault gas in transformer oil based on fiber enhancement

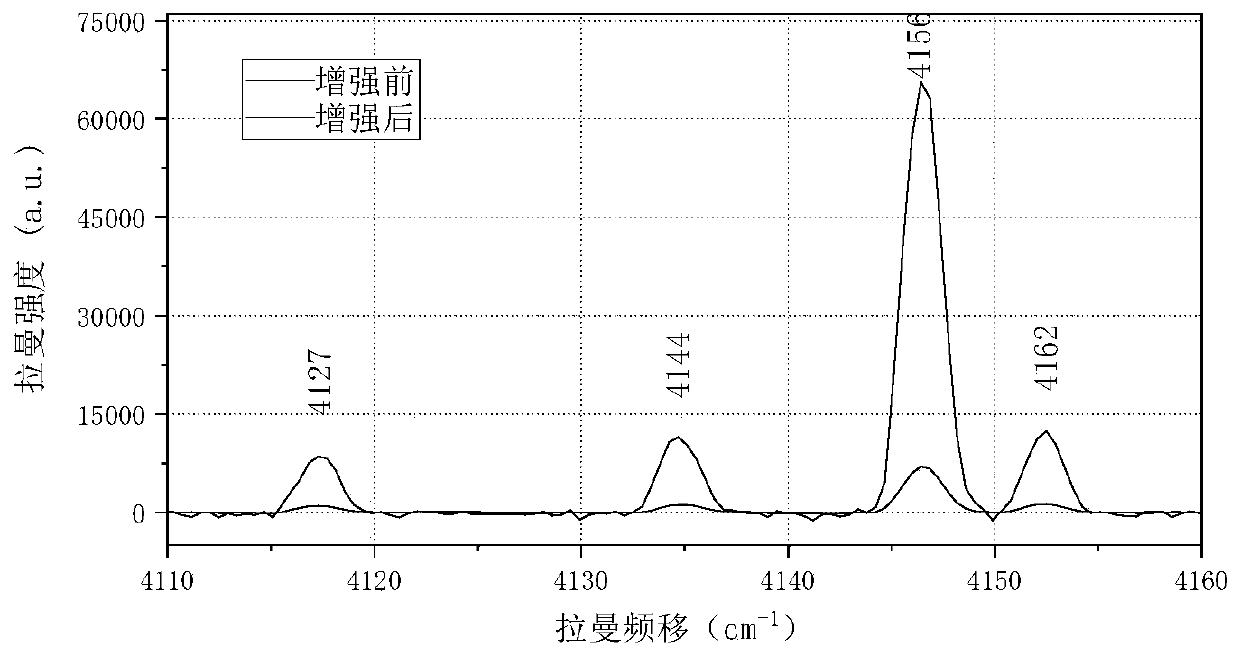

A technology for transformer oil and fault gas is applied in the field of on-line monitoring devices for fault gas in transformer oil, which can solve the problems of low dissolved gas content and low absolute scattering cross section of Raman effect, and achieve the effects of high accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further introduced in detail below in conjunction with the accompanying drawings and specific embodiments.

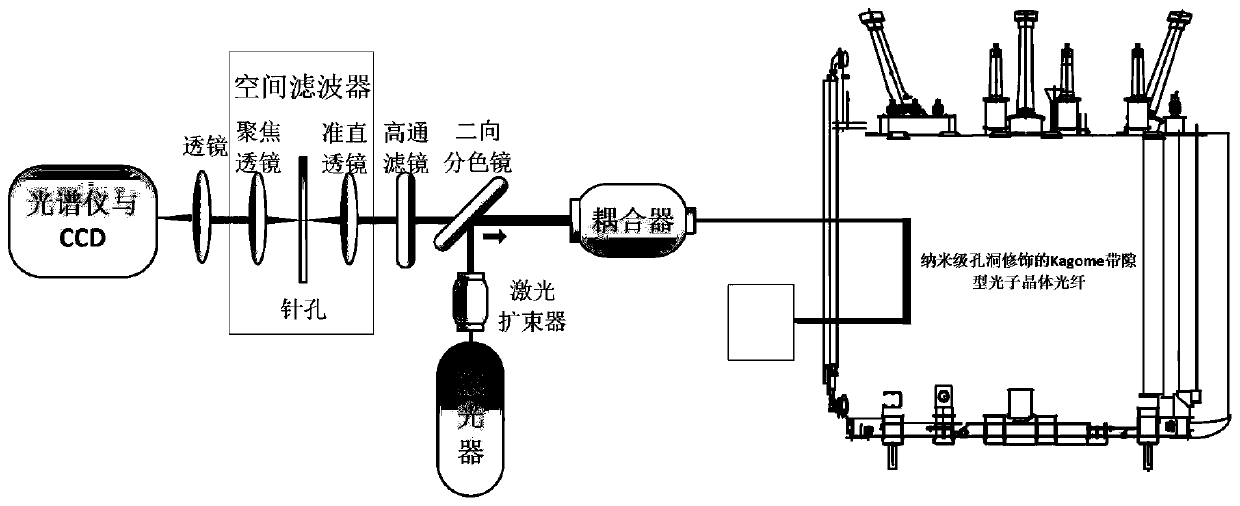

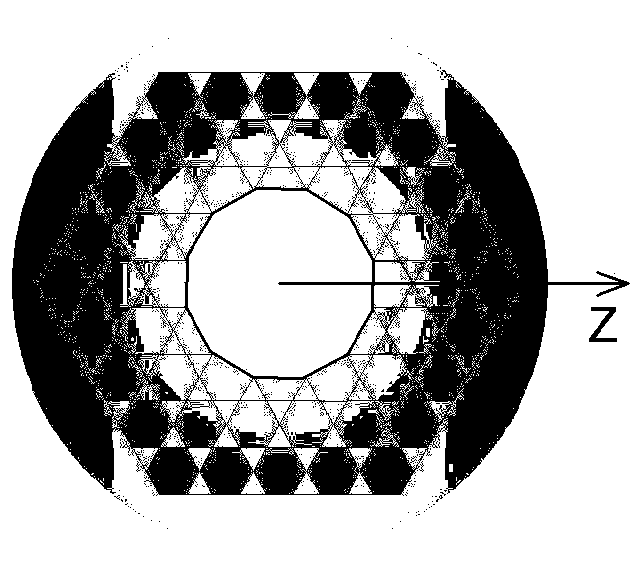

[0029] like figure 1 As shown, a kind of on-line monitoring device for faulty gas in transformer oil based on optical fiber enhancement of the present invention includes a laser, a laser beam expander, a dichroic mirror, a spatial filter, a coupler, a displacement device, and a kagome bandgap photonic crystal Fiber optics, spectrometers. The laser light emitted by the laser passes through the laser beam expander, and the coupler couples the laser light into the kagome bandgap photonic crystal fiber, and the two ends of the spatial filter are respectively connected to lens A and a high-pass filter, and the The spatial filter is composed of a collimating lens, a pinhole and a focusing lens. The CCD of the spectrometer is connected to the lens A, and the lens A plays a focusing role, which is convenient for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com