Method for measuring malonaldehyde content of catalpa bungei leaves

A technology of sheet malondialdehyde and determination method, which is applied in the measurement of color/spectral properties, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of malondialdehyde content. detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

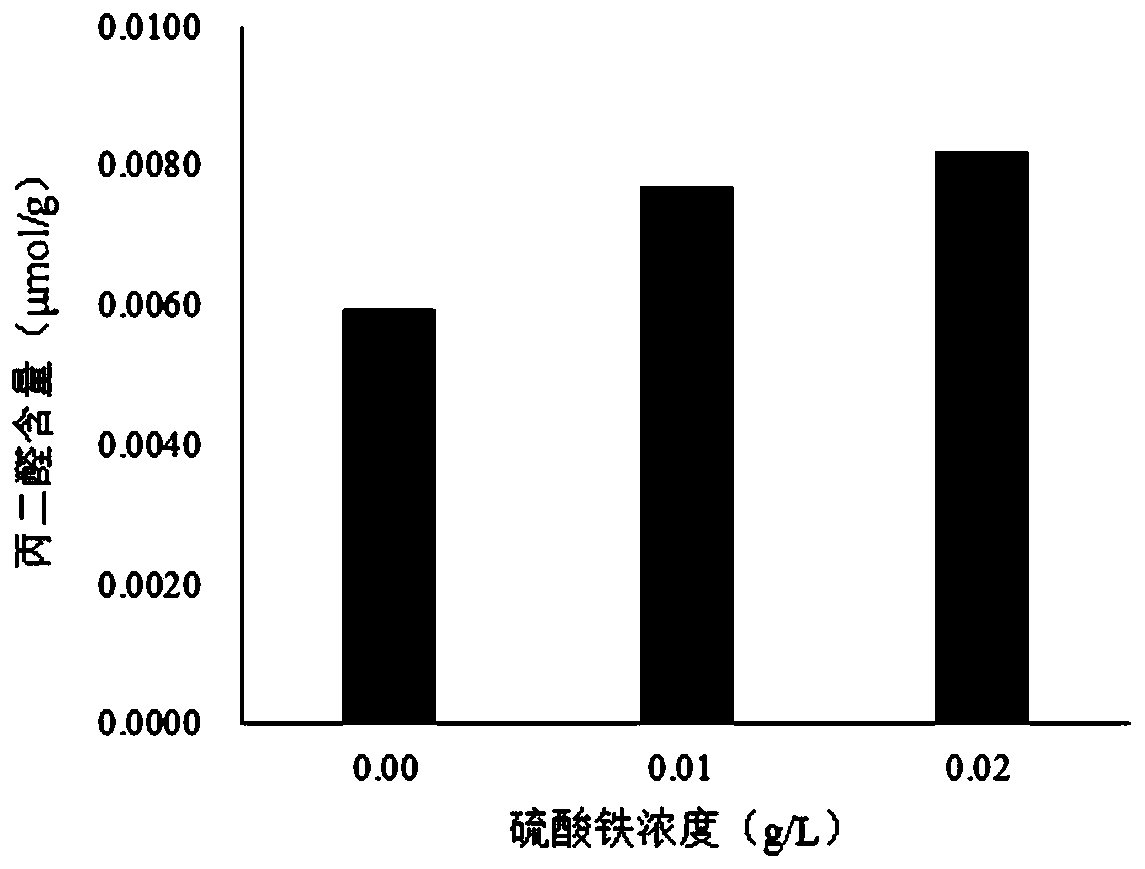

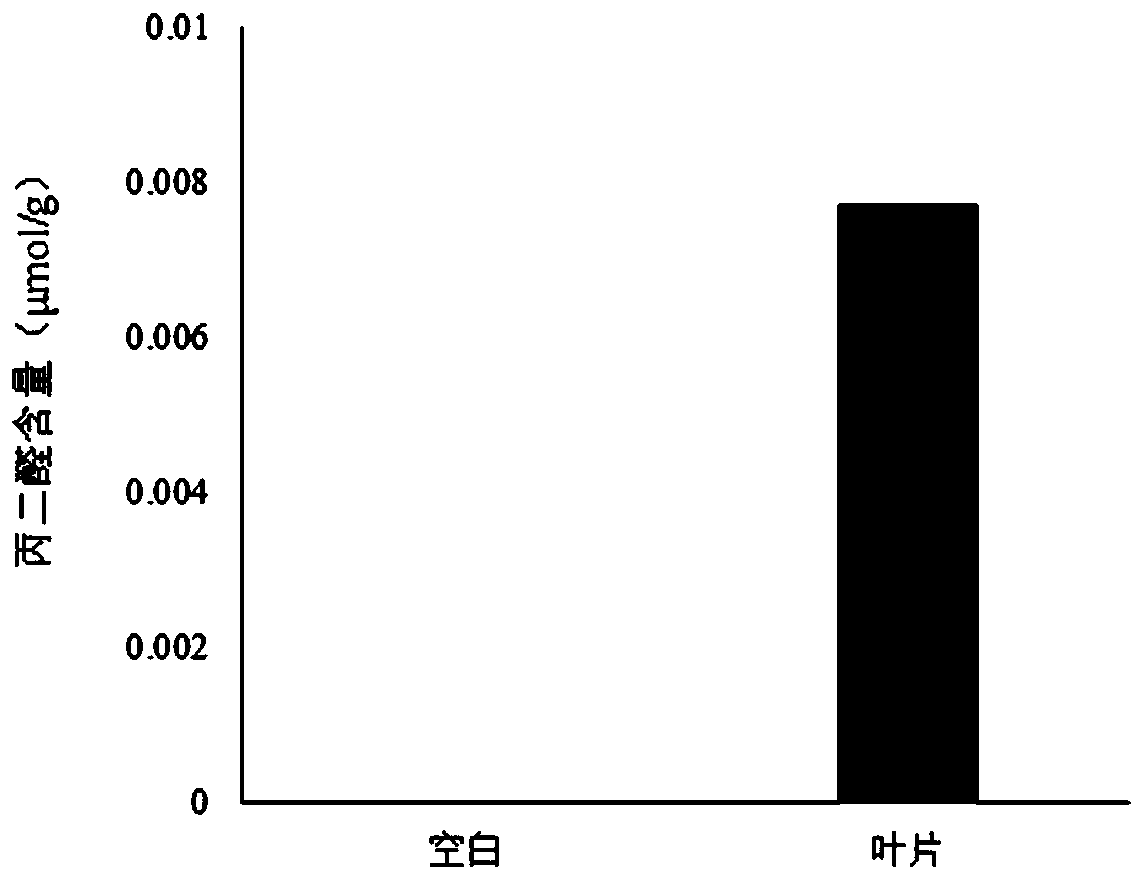

[0035] The detection effect of malondialdehyde content of catalpa leaf under the different concentration of iron sulfate of embodiment 1

[0036] (1) Material

[0037] The young leaves of 1-year-old catalpa seedlings were used as materials.

[0038] (2) Reagent preparation

[0039] Trichloroacetic acid (TCA) solution: configure the concentration of trichloroacetic acid solution to be 0.75%.

[0040] Thiobarbituric acid (TBA) solution: 0.02mol / L.

[0041] Iron Sulfate (Fe 2 (SO 4 ) 3 ) solution: 0.01g / L and 0.02g / L.

[0042] (3) Measurement process

[0043] Grind the leaf sample into powder with liquid nitrogen, weigh 4.50g (accurate to 0.01g) of the sample powder, place it in a stoppered Erlenmeyer flask, add 45mL TCA solution accurately, shake well and stopper, place it on a constant temperature shaker at 50°C 30min, the rotation frequency is 110rpm, take it out, filter with filter paper, and take the filtrate for later use.

[0044] Take 9 extracts respectively and ...

Embodiment 2 3

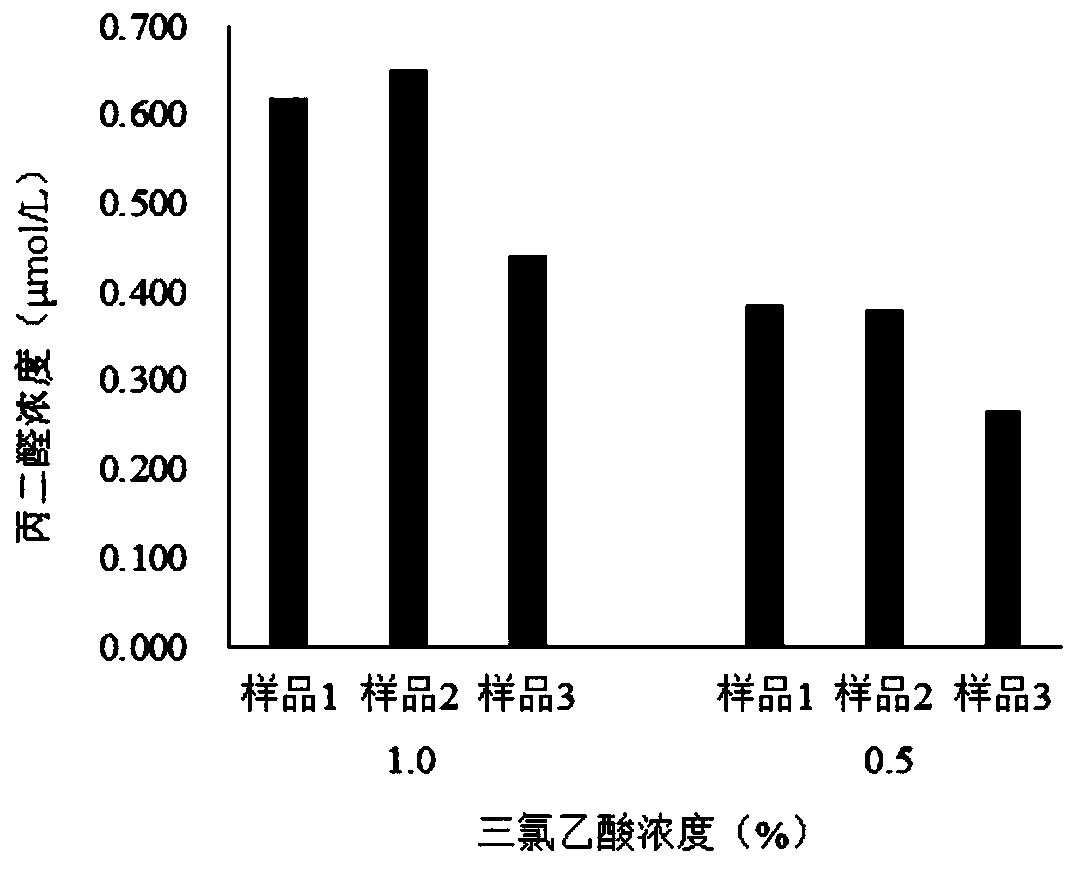

[0047] The detection effect of catalpa leaf malondialdehyde content under the different concentrations of embodiment 2 trichloroacetic acid

[0048] (1) Material

[0049] The young leaves of three 1-year-old catalpa grafted seedlings were used as materials, and they were numbered as sample 1, sample 2 and sample 3 respectively.

[0050] (2) Reagent preparation

[0051]Trichloroacetic acid (TCA) solution: prepare the concentration of trichloroacetic acid solution as 0.5% and 1.0%.

[0052] Thiobarbituric acid (TBA) solution: 0.02mol / L.

[0053] Iron Sulfate (Fe 2 (SO 4 ) 3 ) solution: 0.02g / L.

[0054] (3) Measurement process

[0055] First, according to the design of 3 repetitions of 2 concentrations of TCA solutions, accurately weigh 6 parts of sample 1, sample 2 and sample 3, each 1.00g, put them into a mortar, add 2ml of 0.5% and 1.0 % TCA, grind until homogenized, transfer the homogenate to a 25ml centrifuge tube, and wash it with 8ml of TCA with a concentration of...

Embodiment 3

[0060] The influence of embodiment 3 different temperatures on MDA extraction effect

[0061] (1) Material

[0062] The leaves of 1-year-old catalpa seedlings were used as materials.

[0063] (2) Reagent preparation

[0064] Trichloroacetic acid (TCA) solution: the concentration is 0.75%.

[0065] Thiobarbituric acid (TBA) solution: the concentration is 0.02mol / L.

[0066] Iron Sulfate (Fe 2 (SO 4 ) 3 ) solution: the concentration is 0.02g / L.

[0067] (3) Measurement process

[0068] First, according to the design of 3 repetitions at 3 temperatures, 9 samples were accurately weighed, each 1.00g, put into a mortar, 2ml of TCA with a concentration of 0.75% was added, ground to a homogenate, and the homogenate was transferred to 25ml centrifuge tube, and rinsed with 8ml of TCA with a concentration of 0.75%; then, shake the centrifuge tube in a constant temperature shaker at 50°C, 60°C, and 70°C for 30min at a rotation frequency of 110rpm; finally, take out the shaken cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com