Stretchable array structure microelectrode, micro supercapacitor and preparation methods thereof

A micro-electrode and array structure technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as weak stretchability, complicated preparation methods, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

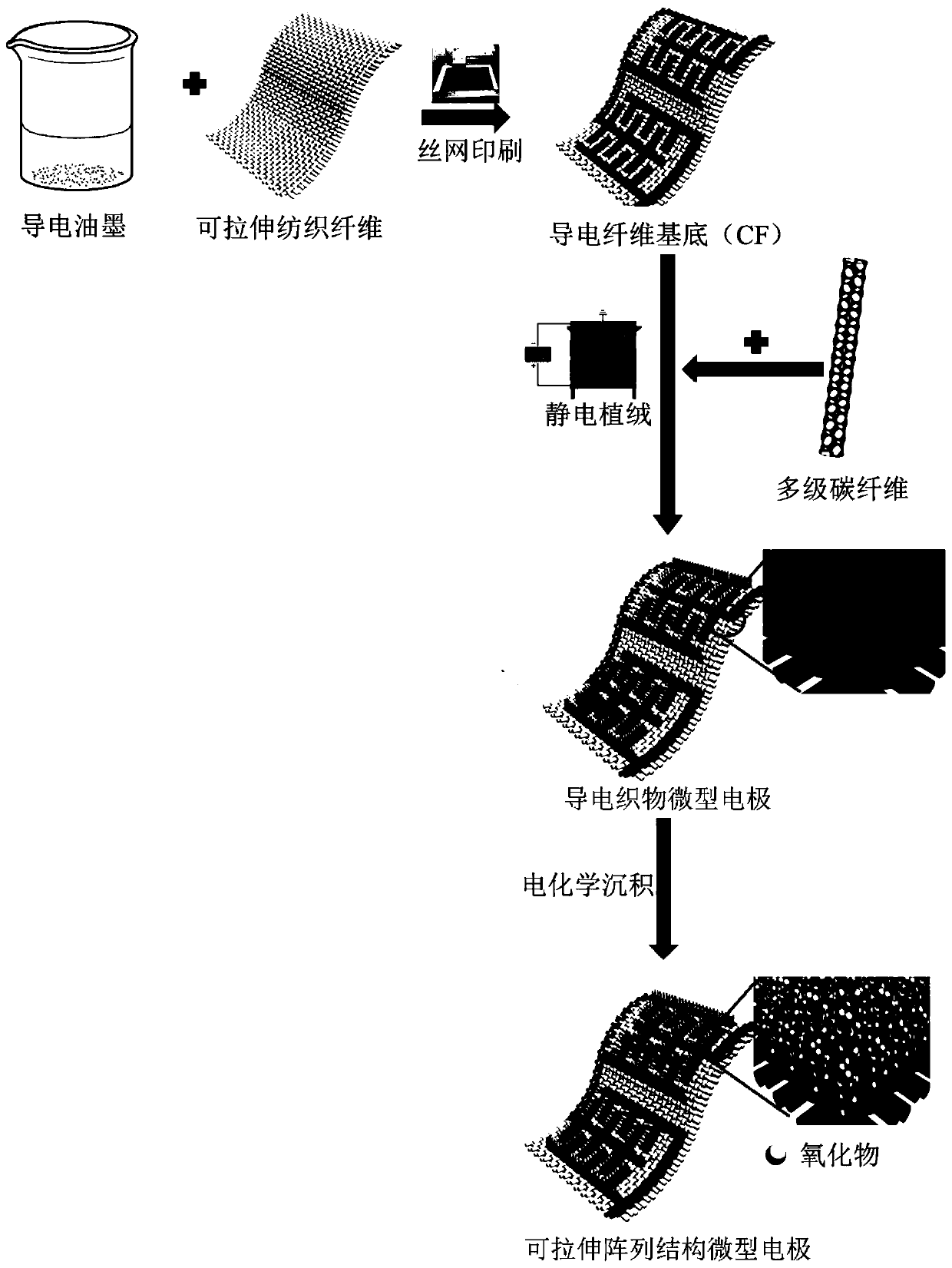

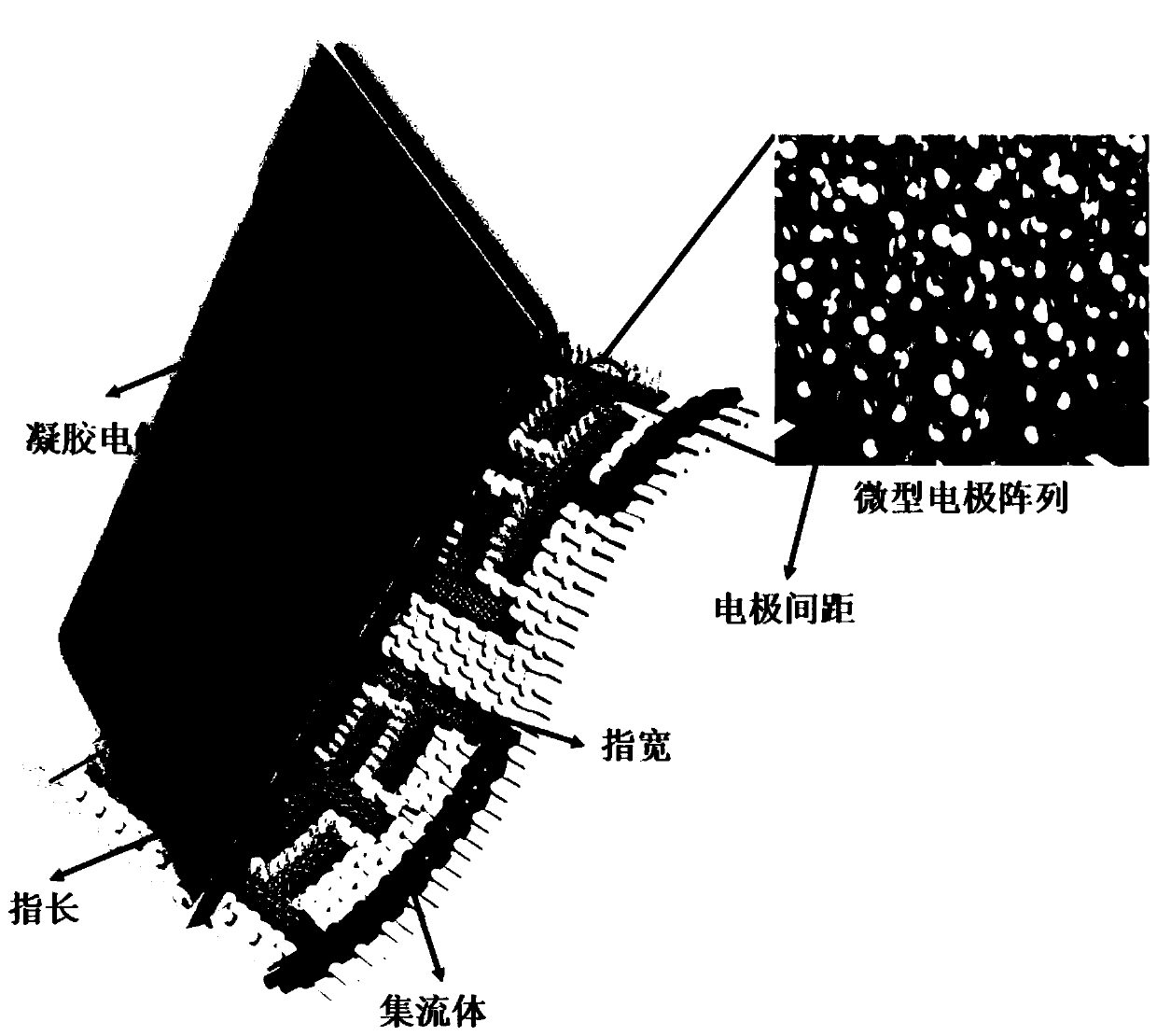

[0029] This embodiment provides a method for preparing a microelectrode with a stretchable array structure, comprising the following steps:

[0030]Step a, adding multi-walled carbon nanotubes to a mixed acid solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, ultrasonically treating at 50°C for 2h, suction filtering, washing with distilled water until neutral, suction filtering, and drying at 80°C °C, dry to constant weight, and grind into uniform fine powder to obtain acidified multi-walled carbon nanotubes; stir the acidified multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate in water evenly, ultrasonically disperse for 1 h, Obtain acidified carbon nanotube stable dispersion liquid; Add ethyl cellulose, hydroxylamine hydrochloride and NMP aqueous solution, stir 15min with precision speed-regulating mixer, obtain conductive ink; Wherein the concentration of each component is: multi-walled carbon nanotube 1.5g / L, sodi...

Embodiment 2

[0036] This embodiment provides a method for preparing a microelectrode with a stretchable array structure, comprising the following steps:

[0037] Step a, adding multi-walled carbon nanotubes to the mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonic treatment at 60°C for 3h, suction filtration, washing with distilled water until neutral, suction filtration, and at 90°C °C, dry to constant weight, and grind into uniform fine powder to obtain acidified multi-walled carbon nanotubes; stir the acidified multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate in water evenly, and ultrasonically disperse for 1.5h , to obtain a stable dispersion of acidified carbon nanotubes; add ethyl cellulose, hydroxylamine hydrochloride and NMP aqueous solution, and stir with a precision speed mixer for 15 minutes to obtain a conductive ink; wherein the concentration of each component is: multi-walled carbon nanotubes 2g...

Embodiment 3

[0043] This embodiment provides a method for preparing a microelectrode with a stretchable array structure, comprising the following steps:

[0044] Step a, adding multi-walled carbon nanotubes to the mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonic treatment at 70°C for 4h, suction filtration, washing with distilled water to neutrality, suction filtration, at 100 ℃, dried to constant weight, and ground into a uniform fine powder to obtain the acidified multi-walled carbon nanotubes; the acidified multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate were stirred evenly in water, ultrasonically dispersed for 2 hours, Obtain a stable dispersion of acidified carbon nanotubes; add ethyl cellulose, hydroxylamine hydrochloride and NMP aqueous solution, stir with a precision speed mixer for 15 minutes, and obtain a conductive ink; wherein the concentration of each component is: multi-walled carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com