Hybrid zinc-nickel redox flow battery

A flow battery and hybrid technology, which can be used in regenerative fuel cells and other directions, can solve the problems of low solid-phase electrode surface capacity and difficulty in meeting the capacity requirements of large-scale energy storage batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

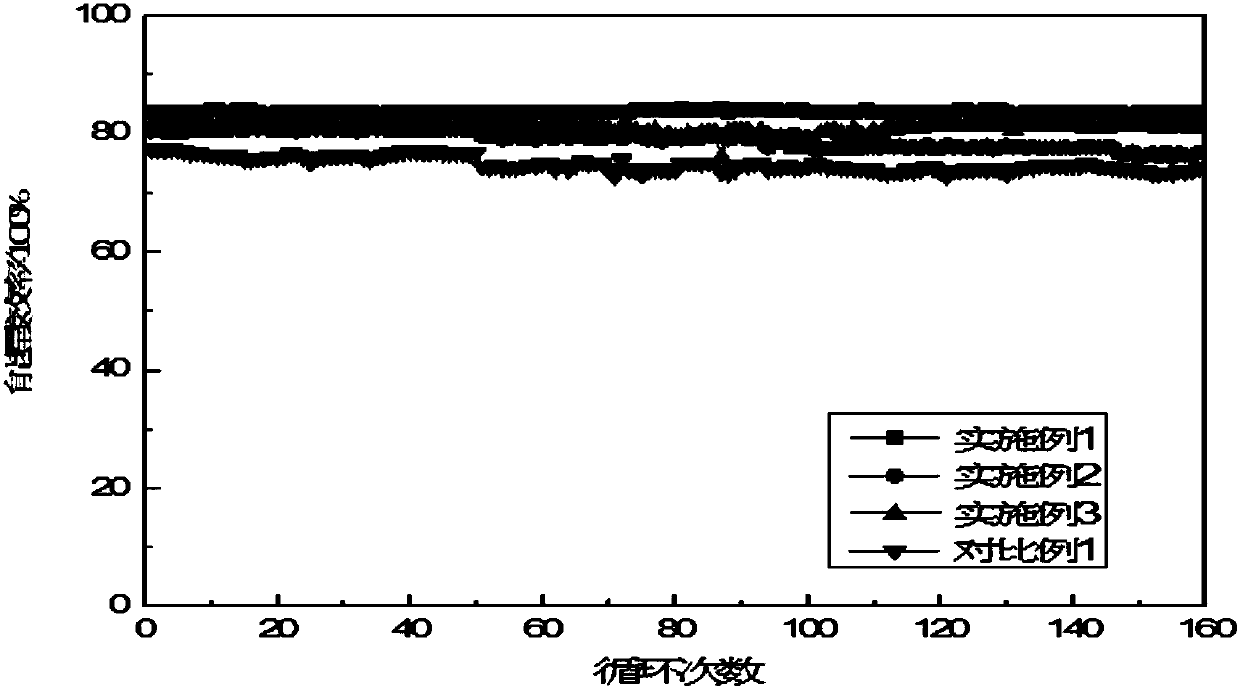

Embodiment 1

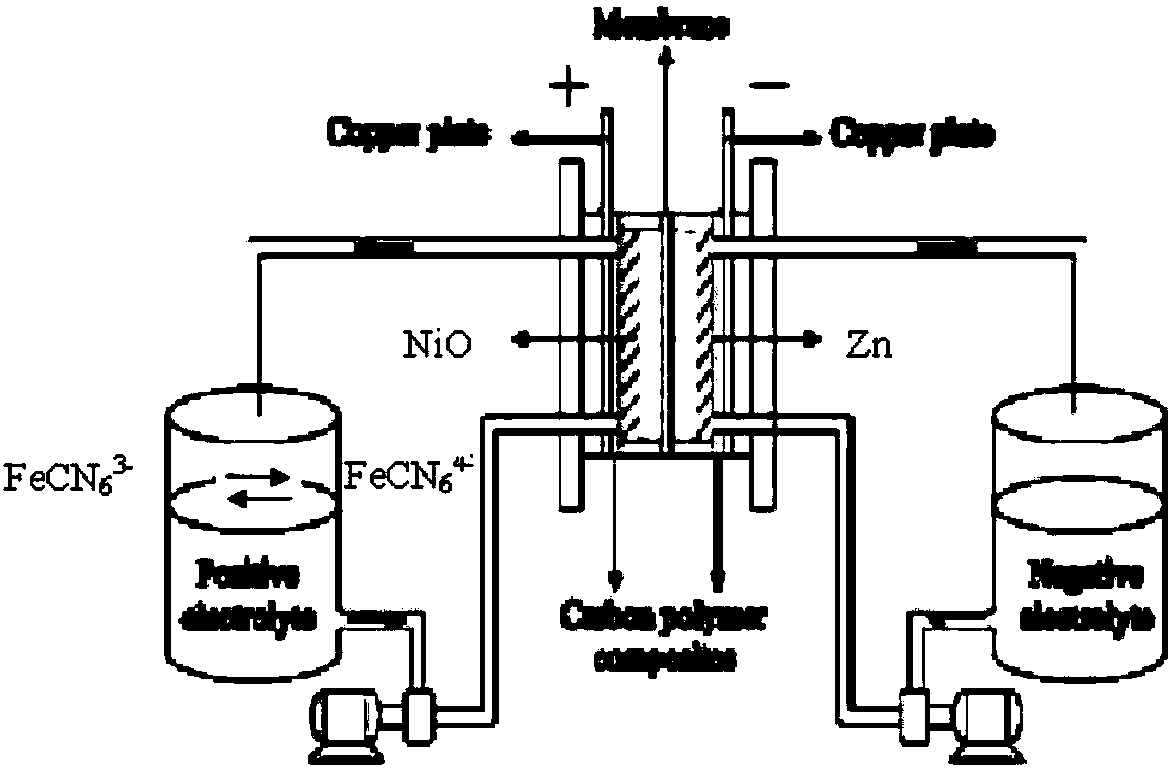

[0021] Hybrid zinc-nickel flow battery:

[0022] 1) The positive electrode uses a 5*5cm NiO electrode;

[0023] 2) The negative electrode uses 5*5cm carbon felt (5mm thickness) and 5*5cm zinc sheet (1mm thickness);

[0024] 3) Use 30 mL of 0.2 mol / L potassium ferrocyanide in 3 mol / L potassium hydroxide solution as the positive electrode electrolyte;

[0025] 4) Negative electrode electrolyte adopts 3mol / L potassium hydroxide solution of 0.5mol / L zinc ion of 30mL;

[0026] 5) The diaphragm adopts cationic membrane Nafion115;

[0027] 6) Battery at 40mA / cm 2 Under charge and discharge, charging time: 1h, discharge cut-off voltage: 1.0V.

Embodiment 2

[0029] Hybrid zinc-nickel flow battery:

[0030] 1) The positive electrode uses a 5*5cm NiO electrode;

[0031] 2) The negative electrode uses 5*5cm carbon felt (5mm thickness) and 5*5cm zinc sheet (1mm thickness);

[0032] 3) The positive electrode electrolyte is 30 mL of 8 mol / L potassium hydroxide solution of 0.5 mol / L potassium ferrocyanide;

[0033] 4) Negative electrode electrolyte adopts 8mol / L potassium hydroxide solution of 0.8mol / L zinc ion of 30mL;

[0034] 5) The diaphragm adopts cationic membrane Nafion115;

[0035] 6) Battery at 40mA / cm 2 Under charge and discharge, charging time: 1h, discharge cut-off voltage: 1.0V.

Embodiment 3

[0037] Hybrid zinc-nickel flow battery:

[0038] 1) The positive electrode uses a 5*5cm NiO electrode;

[0039] 2) The negative electrode uses 5*5cm carbon felt (5mm thickness) and 5*5cm zinc sheet (1mm thickness);

[0040] 3) The positive electrode electrolyte adopts 30mL of 6mol / L potassium hydroxide solution of 1mol / L potassium ferrocyanide;

[0041] 4) Negative electrode electrolyte adopts 6mol / L potassium hydroxide solution of 0.1mol / L zinc ion of 30mL;

[0042] 5) The diaphragm adopts cationic membrane Nafion115;

[0043] 6) Battery at 40mA / cm 2 Under charge and discharge, charging time: 1h, discharge cut-off voltage: 1.0V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com