Improved process for the production of fucosylated oligosaccharides

A technology of fucosyl and oligosaccharides, applied in biochemical equipment and methods, glycosyltransferases, oxidoreductases, etc., can solve problems such as inability to achieve HMO titer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

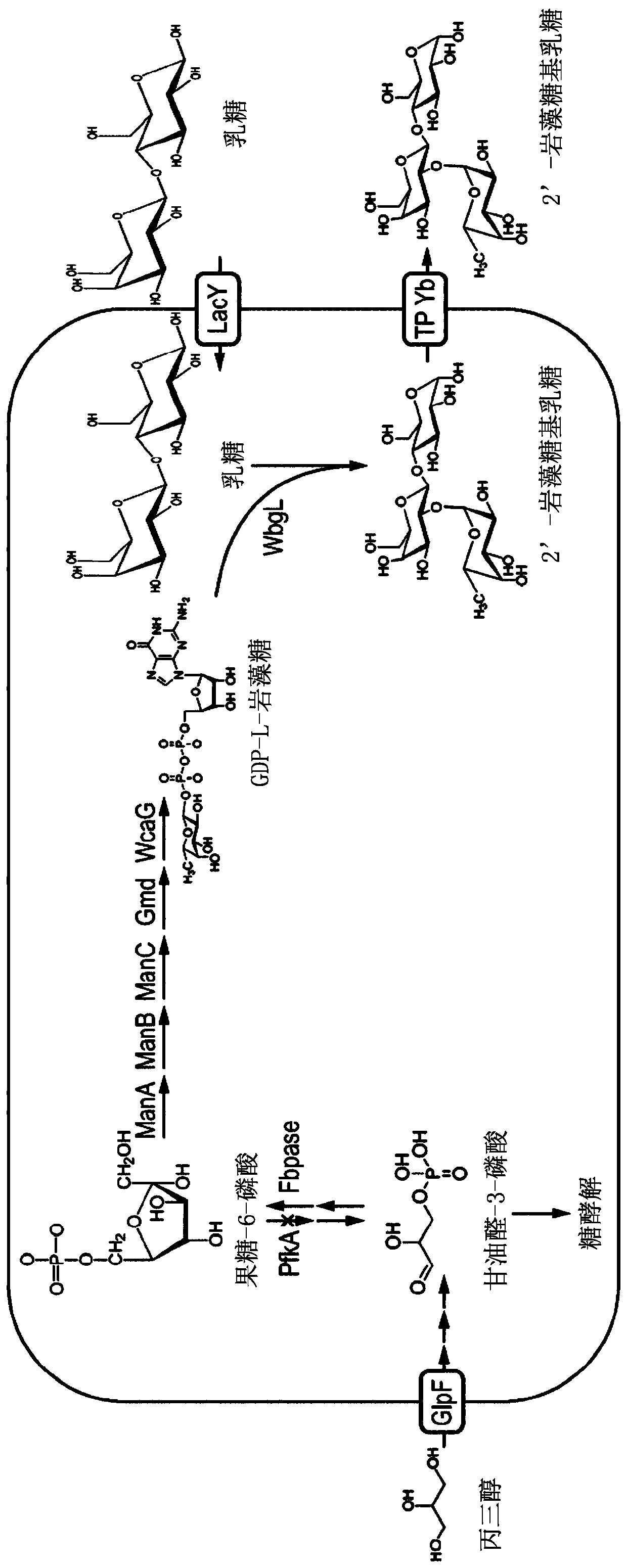

[0112] Transformation of Escherichia coli BL21(DE3) strain for producing 2'-fucosyllactose

[0113] Using Escherichia coli BL21(DE3) as a parental host, a strain for producing 2'-fucosyllactose in a whole-cell biosynthesis method was constructed. Genome engineering of the strains includes gene disruption and deletion events as well as integration of heterologous genes.

[0114] Since 2'-fucosyllactose is synthesized from lactose (suitable for bacterial cultures), and from GDP-L-fucose produced in living cells, the encoding Inactivation of the wild-type copy of the lacZ gene of the endogenous β-galactosidase (see Ellis et al., "High efficiency mutagenesis, repair, and engineering of chromosome DNA using single-stranded oligonucleotides", Proc. Natl. Acad. Sci. USA 98:6742-6746 (2001)). Using the same method, the arabinose isomerase gene araA was disrupted.

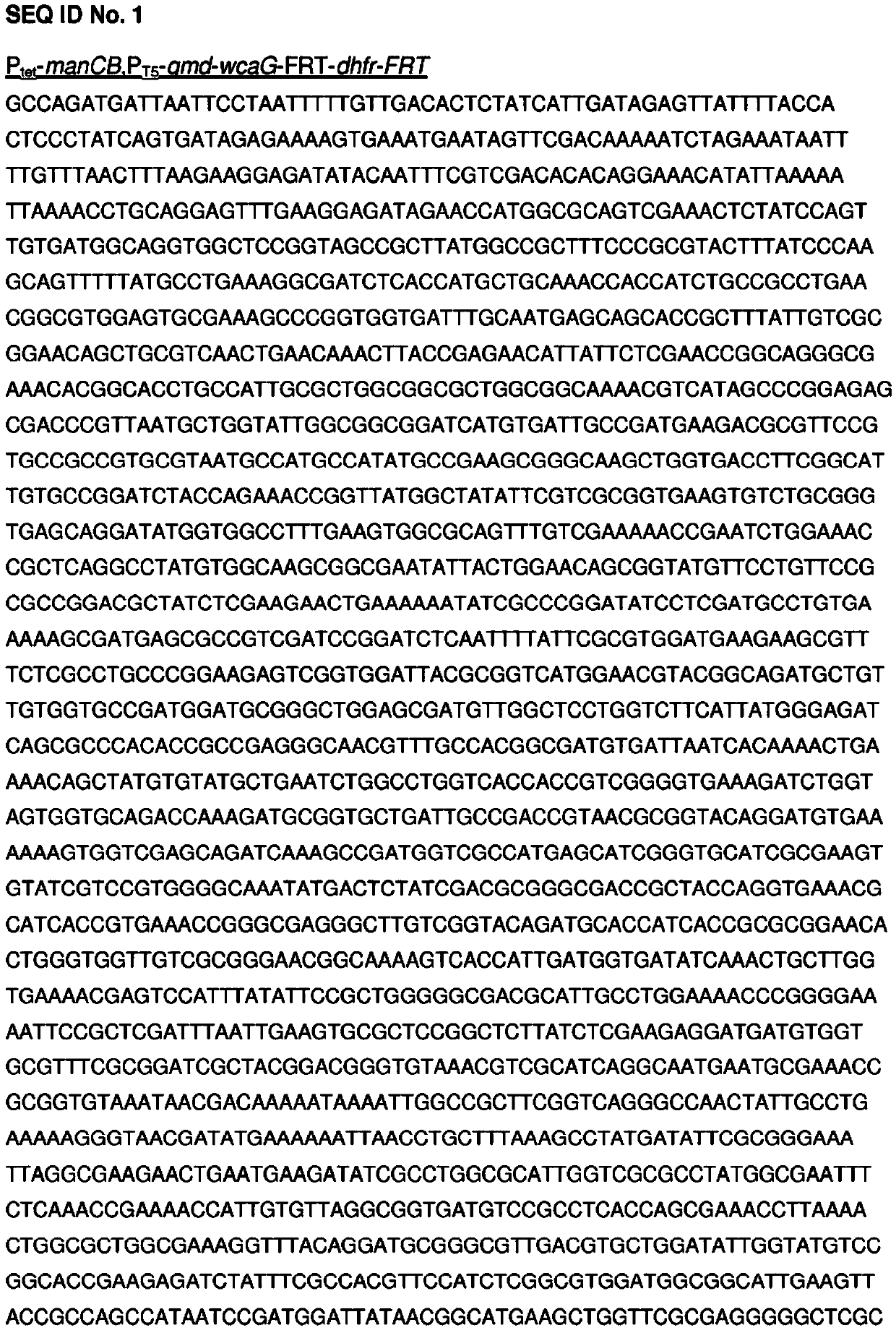

[0115] The lacZΩ gene fragment was introduced under the control of the temperature-sensitive transcriptional repress...

Embodiment 2

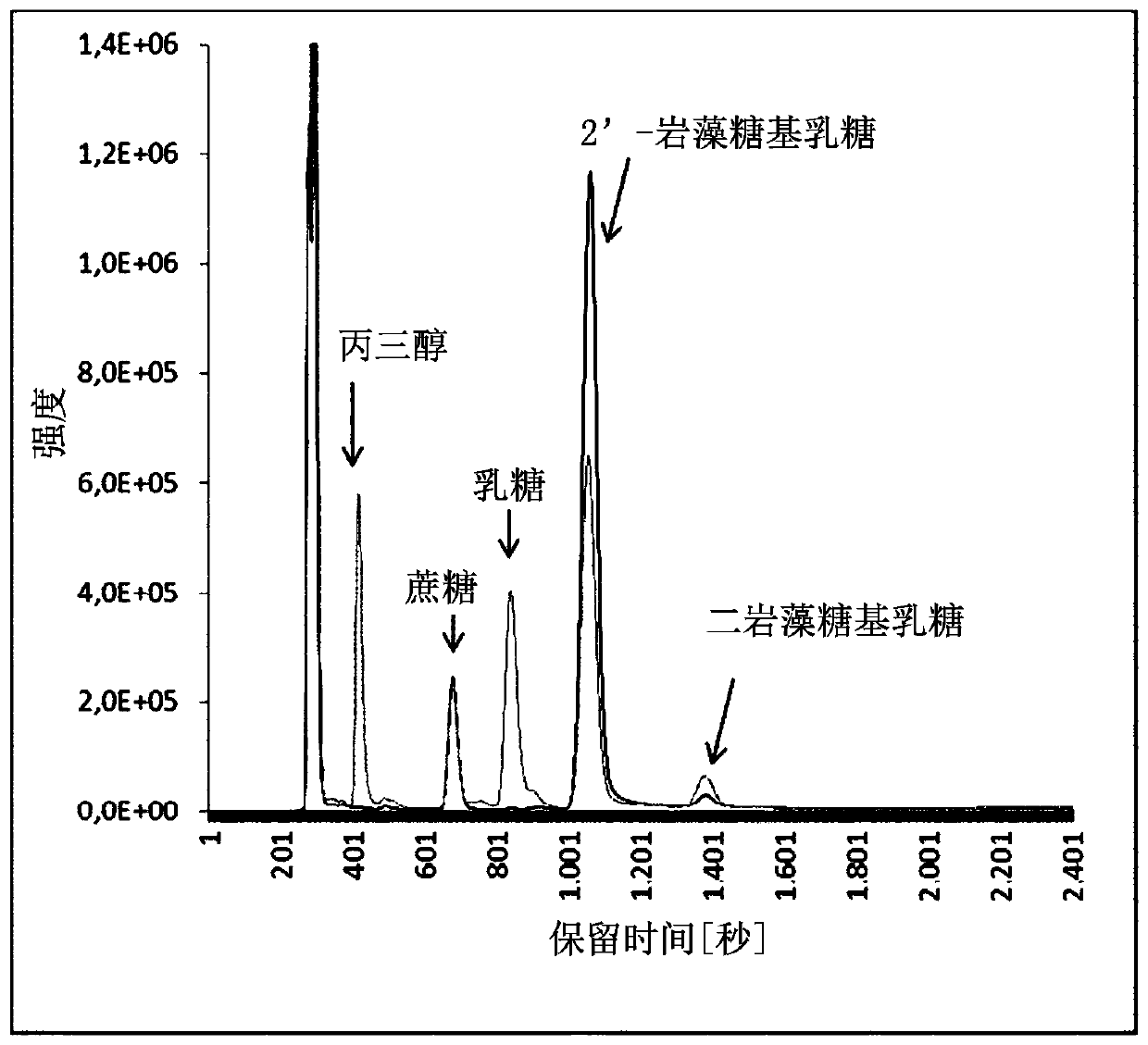

[0121] Confirmation of increased 2'-fucosyllactose export by the Yersinia burgdorferi ATCC 43970 sugar efflux transporter

[0122] Knockout of yberc0001_9420

[0123] To demonstrate the functionality of the heterologous sugar transporter from Yersinia burgdorferi ATCC 43970, the gentamicin resistance cassette aacC1 from plasmid pBBR-MCS5 was used (Kovach, Elzer et al. 1995, "Four new derivatives of the broad-host-range cloning vector pBBRI MCS, carrying different antibiotic-resistance cassettes", Gene 166, 175-176) - which was inserted into the gene yberc0001_9420 from strain E. coli BL21(DE3) lacZ - 、araA - 、fucl - 、fucK - , wcaJ - (which contained manB, manC, gmd, wcaG, lacY, wbgL, and yberc0001_9420 chromosomal integration by homologous recombination of Datsenko and Wanner (2000; see above)) the gene yberc0001_9420 was deleted, resulting in strain Δyberc0001_9420.

[0124] Culture conditions for 2’-fucosyllactose production

[0125] The Escherichia coli BL21(DE3...

Embodiment 3

[0132] Production of 2’-fucosyllactose during fermentation

[0133] Fermentations were carried out in 3 L fermenters at 30°C and pH 7.0; the pH was adjusted by titration with 25% ammonia. The strain described in Example 2 was cultivated in the mineral salt medium described in Example 2 using glycerol as a carbon source and energy source. A fermenter with an initial volume of 1 L was inoculated with a preculture grown in the same medium. Glycerol was added continuously (60% v / v) after the 2% glycerol contained in the batch was consumed. When OD 600nm When 6 was reached, lactose was added at a concentration of 0.66 M in three portions (10 ml each) (1 hour apart). Thereafter, lactose was administered in a continuous flow to maintain a lactose concentration in the fermentor of at least 10 mM. After culturing for 86 h, the final titer of 91.3 mM (44.6 g / L) 2'-fucosyllactose was reached. By changing the temperature to 42°C and expressing the β-galactosidase gene, lactose and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com