Sintered compact for forming rare earth sintered magnet, and method for manufacturing same

A technology of sintered magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, manufacturing motor generators, etc., can solve the problems of uneven and uneven magnet structure, and achieve the effect of suppressing shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

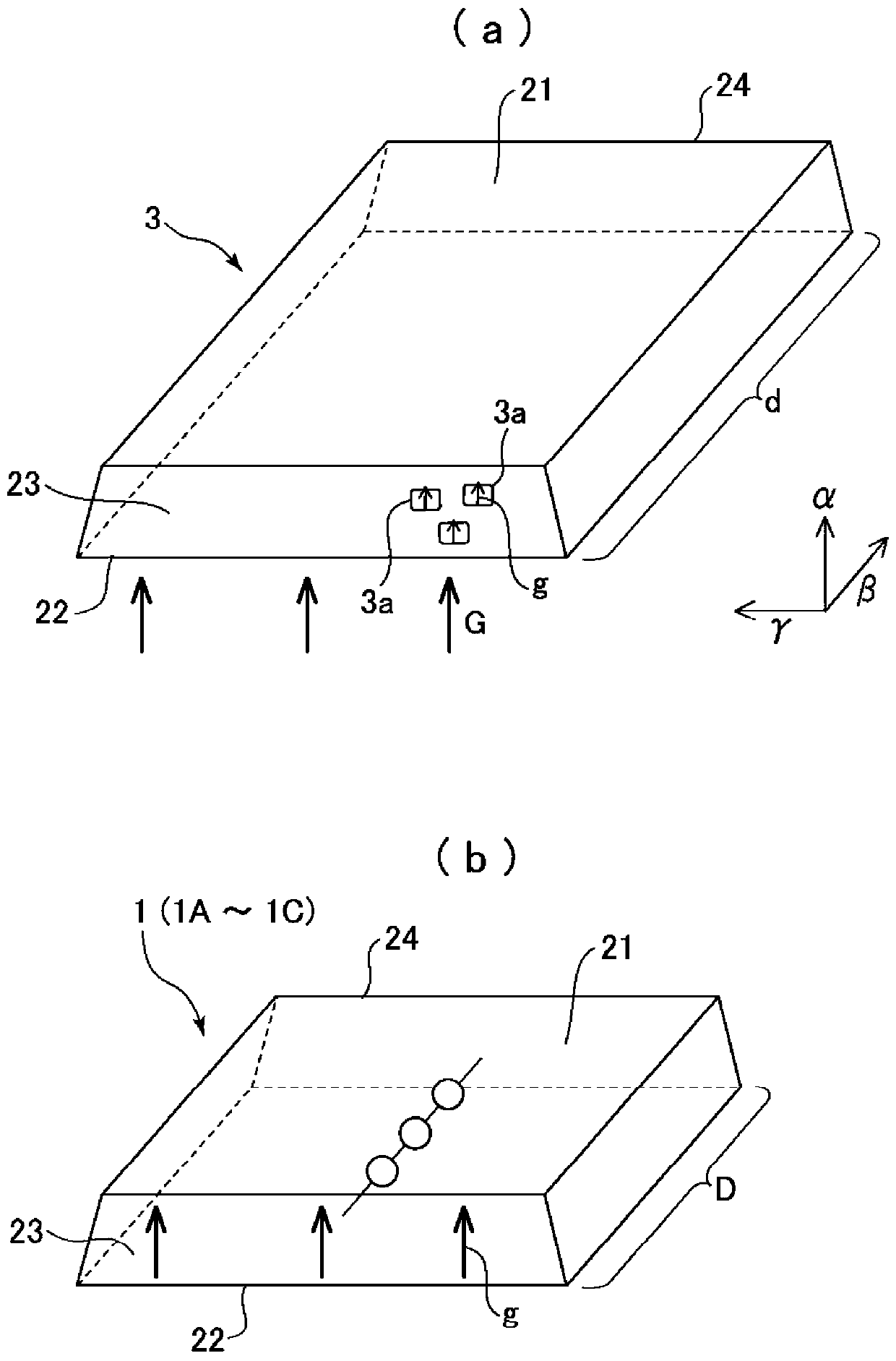

[0171] use Figure 9 A sintered body was produced in the following procedure for the trapezoidal processing sheet shown. No deoiling treatment was performed.

[0172]

[0173] The alloy obtained by the strip casting method was allowed to occlude hydrogen at room temperature and kept at 0.85 MPa for 1 day. Then, hydrogen fragmentation was carried out by maintaining at 0.2 MPa for 1 day while cooling with liquid Ar. The composition of the alloy is "comprising Nd: 25.25wt%, Pr: 6.75wt%, B: 1.01wt%, Ga: 0.13wt%, Nb: 0.2wt%, Co: 2.0wt%, Cu: 0.13wt%, the rest Fe, Al: 0.10wt%, and other unavoidable impurities".

[0174]

[0175] Fine pulverization was carried out by jet mill pulverization as follows. 1 part by weight of methyl hexanoate was mixed with 100 parts by weight of the coarse alloy powder subjected to hydrogen pulverization, and then pulverized by a helium jet mill pulverizer (device name: PJM-80HE, manufactured by NPK). The collection of pulverized alloy particles ...

Embodiment 2~9、 comparative example 1~5

[0193] Except having changed to the conditions described in Table 1, the same operation as Example 1 was performed, and each sintered body was obtained.

[0194] From Examples 2 to 9, it is clear that the high-temperature heat treatment "B" at 970°C for 2 to 11 hours after pressure sintering exhibits a coercive force Hcj of 16.4 [kOe] or more, and the squareness Hk / Hcj It is also shown as 90% or more.

[0195] On the other hand, as shown in Comparative Examples 1 and 4, when the high-temperature heat treatment "B" is not performed, although the squareness Hk / Hcj exceeds 90%, the coercive force Hcj can only be obtained at about 12 [kOe] very low value.

[0196] In addition, as shown in Comparative Examples 2 and 3, when the temperature of the high-temperature heat treatment "B" was as low as 700°C or 900°C, the temperature was lower than that in the case of not performing the high-temperature heat treatment "B" shown in Comparative Examples 1 and 4. Compared with that, almost...

Embodiment 10~17、 comparative example 6、7

[0199] The same evaluation and analysis as in Table 1 were performed for the sintered body produced under the conditions in Table 1 or the rare earth sintered magnet obtained by magnetizing the same. The results are shown in Table 2. In addition, the conditions other than the conditions especially described in Table 2 were made into the same conditions as Example 1.

[0200]

[0201] In Table 2, the alloy composition "A" refers to the alloy composition used in Example 1, on the other hand, the alloy composition "B" refers to "containing Nd: 22.25wt%, Dy: 3.00wt%, Pr: 6.75wt% %, B: 1.01wt%, Ga: 0.13wt%, Nb: 0.2wt%, Co: 2.0wt%, Cu: 0.13wt%, the remainder is Fe, Al: 0.10wt%, and other unavoidable impurities" .

[0202] In Table 2, by setting the feed rate of the raw material during pulverization to 4.3 kg / h, the pulverized particle size of the fine pulverization which is the basis of the rare earth magnet forming material is set to about 3 μm.

[0203] In addition, in the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com