System for removing SO3 in exhaust gas by utilizing modified coal-fired fly ash and work method

A working method and modified technology, applied in separation methods, chemical instruments and methods, climate change adaptation, etc., to achieve the effects of good environmental protection, wide economic benefits, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0019] Example.

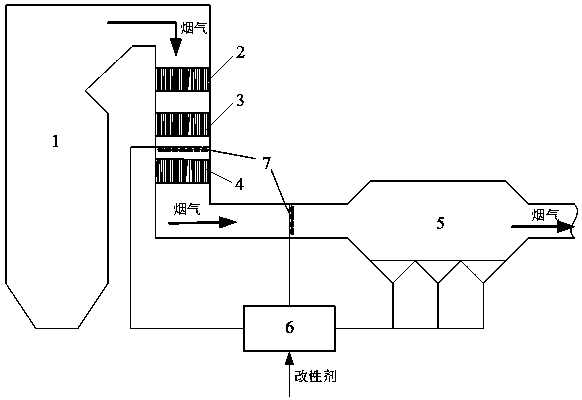

[0020] see figure 1 , the modified coal-fired fly ash in this example removes SO from flue gas 3 system, including boiler 1, economizer 2, SCR denitrification reactor 3, air preheater 4, dust collector 5, ultrasonic atomization device 6 and modified fly ash injection device 7;

[0021] The boiler 1, the economizer 2, the SCR denitrification reactor 3, the air preheater 4 and the dust collector 5 are connected in sequence, and the modified fly ash injection device 7 is arranged between the SCR denitrification reactor 3 and the air preheater 4, and / or The modified fly ash injection device 7 is arranged between the air preheater 4 and the dust collector 5; the ultrasonic atomization device 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com