Method for realizing large-size slender thin-wall I-shaped beam structure composite part through open air bag

A composite material and open-type technology, applied in the field of high-performance carbon fiber composite structural parts manufacturing, can solve the problems of irreparable, high manufacturing and maintenance costs of metal mandrels, affecting the profile, etc., to reduce the manufacturing cycle and raw material costs, The post-maintenance is simple and the effect of improving the qualification rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

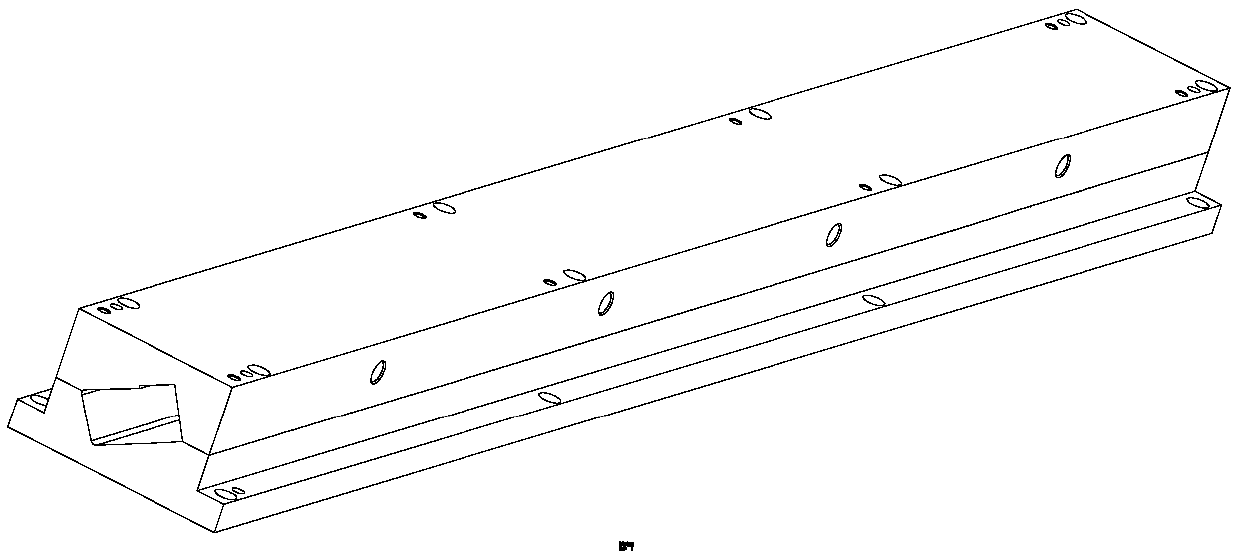

[0029] figure 1 It is a combined groove-type open airbag forming mold with the same size as the left and right inner cavity of the I-beam structure composite material forming mold. Firstly, two combined groove-type open airbag forming molds are processed by mechanical manufacturing. Coordinate positioning between them through corresponding positioning pins.

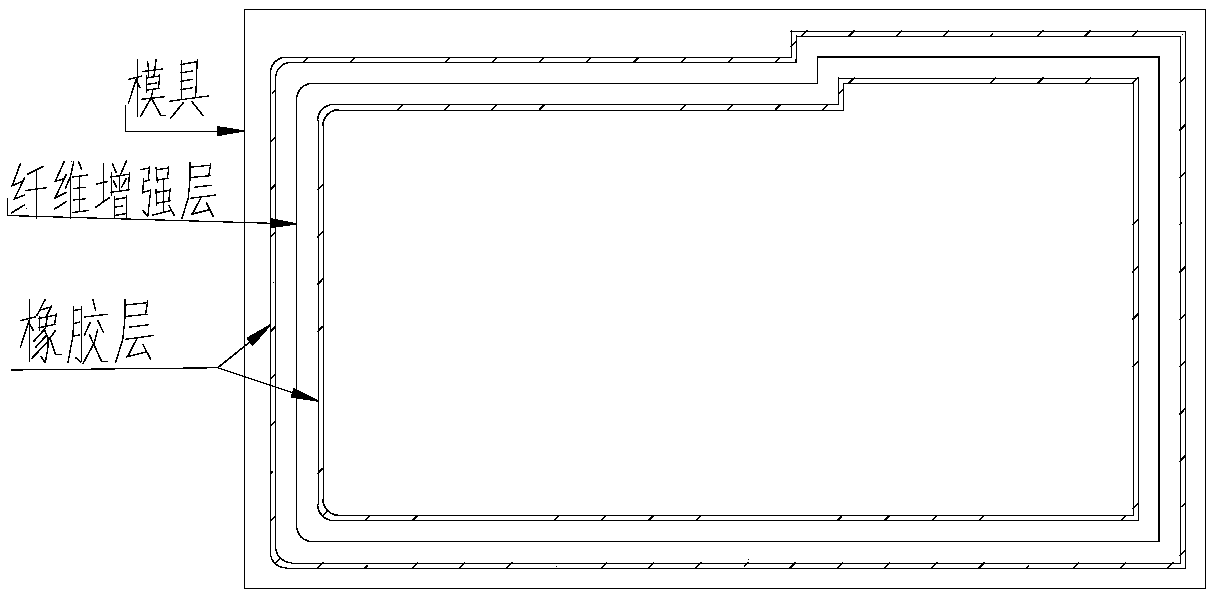

[0030] figure 2 It is a schematic diagram of paving a grooved open airbag in a combined grooved open airbag forming mold, using the cavity formed after the combination of two grooved molds to lay the airbag. The airbag uses rubber as the main material, and the rubber is laid layer by layer in the cavity, and carbon fiber prepreg is laid in the middle of the rubber layer as a reinforcement layer to improve the overall rigidity of the airbag. The number of layers of rubber and prepreg is main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com