Organic silicone elastomer synthesized by means of ultraviolet light catalysis hydrosilylation and preparation method thereof

A technology for catalyzing the addition of silicon and hydrogen by ultraviolet light, which is applied in the field of silicone elastomers, can solve the problems of large amount of catalyst used, harsh preparation conditions, yellowing of products, etc., and achieves simple preparation method, reduced production cost, and reduced yellowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

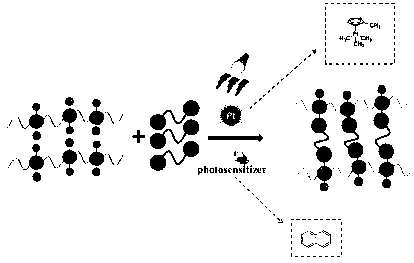

Method used

Image

Examples

Embodiment 1

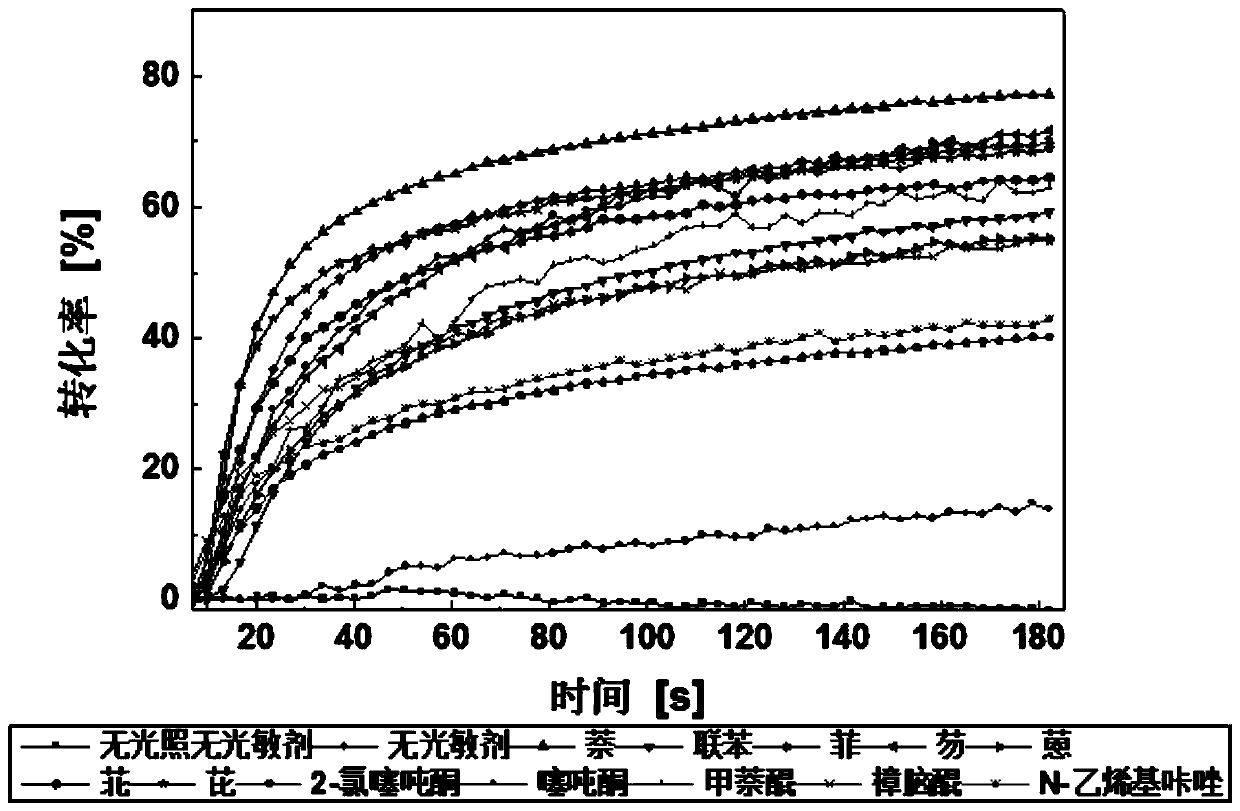

[0029] The preparation of a silicone elastomer prepared by ultraviolet photocatalytic hydrogen silylation addition uses the following raw materials: 100g 5000cst (normal temperature) vinyl-terminated silicone oil, 10g 20cst hydrogen-containing silicone oil, stir and mix evenly, and then add 0.01g trimethyl (formazol Cyclopentadienyl) platinum (IV), 0.04g photosensitizer naphthalene, and 0.01g diethyl fumarate were stirred and mixed evenly, and then the above mixture was shaken out of bubbles by ultrasonic vibration, and then passed through a light intensity of 50mW / cm 2 UV radiation for 3 minutes to obtain the silicone elastomer.

Embodiment 2

[0031]The preparation of a silicone elastomer prepared by UV-catalyzed hydrosilicon addition adopts the following raw materials: 100g of 5000cst vinyl-terminated silicone oil, 10g of 20cst hydrogen-containing silicone oil, stir and mix evenly, and then add 0.01g of trimethyl (methyl Cyclopentadienyl) platinum (IV), 0.04g photosensitizer phenanthrene, and 0.01g diethyl fumarate were stirred and mixed evenly, and then the above-mentioned mixture was shaken out of bubbles by ultrasonic vibration, and then passed through a light intensity of 50mW / cm 2 UV radiation for 3 minutes to obtain the silicone elastomer.

Embodiment 3

[0033] The preparation of a silicone elastomer prepared by ultraviolet photocatalytic hydrosilicon addition adopts the following raw materials: 100g 5000cst vinyl-terminated silicone oil, 10g 20cst hydrogen-containing silicone oil, stir and mix evenly, and then add 0.01g trimethyl (methylcyclopentyl) Dienyl) platinum (IV), 0.04g photosensitizer perylene, and 0.01g diethyl fumarate were stirred and mixed evenly, and then the above-mentioned mixture was shaken out of bubbles by ultrasonic vibration, and then passed through a light intensity of 50mW / cm 2 UV radiation for 3 minutes to obtain the silicone elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com