A kind of biomass catalytic pyrolysis method

A technology of catalytic pyrolysis and biomass, which is applied in the field of biomass energy conversion and utilization, can solve the problems of less research, achieve strong adsorption performance, high yield, and improve the efficiency of conversion and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

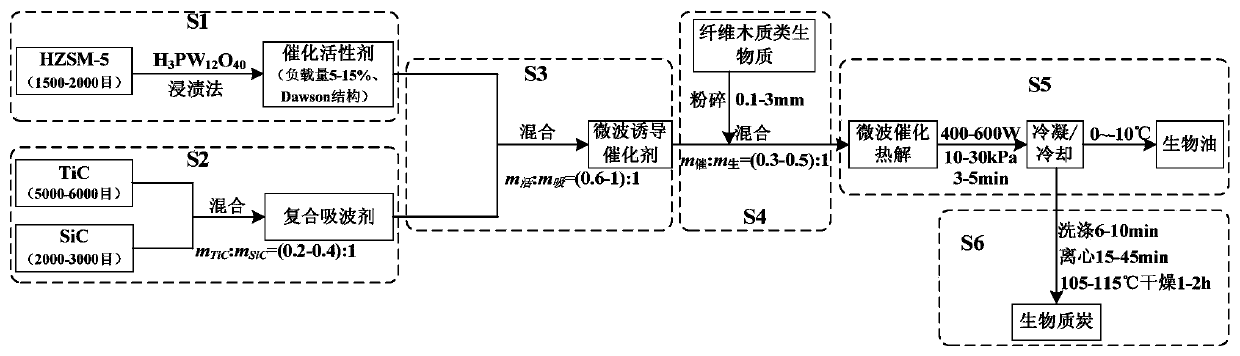

Method used

Image

Examples

Embodiment 1

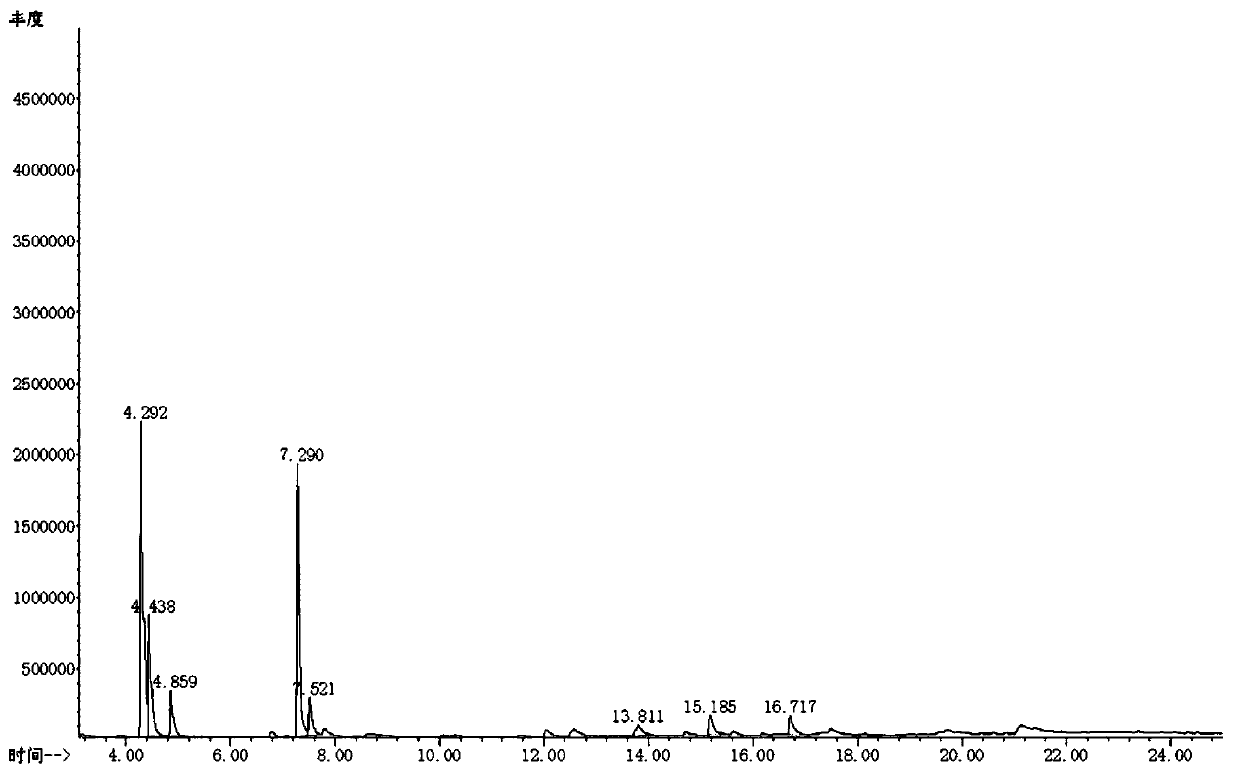

[0033]Prepare the loaded phosphotungstic acid HZSM-5 active agent by impregnation method, the loading of phosphotungstic acid (hereinafter referred to as PW) is 5%, that is, 5% PW / HZSM-5, and the loaded PW is Dawson structure; TiC and SiC The powder is mixed to make a composite wave absorbing agent with a mass ratio of 0.2:1; the active agent and wave absorbing agent are mixed at a ratio of 0.6:1 to make a microwave-induced catalyst; the prepared catalyst and biomass particles (from agricultural and forestry straw) After mixing evenly, put it into the microwave reactor. The average particle size of biomass particles is 0.3mm, the mass ratio of catalyst to biomass is 0.3:1, the microwave power is adjusted to 400W, the vacuum pressure is 10kPa, and the reaction time is 3min. The product bio-oil was obtained after fully condensing and cooling at 0°C under the suction of the pump; the solid residue mixture in the reactor was washed with distilled water for 6 minutes, centrifuged fo...

Embodiment 2

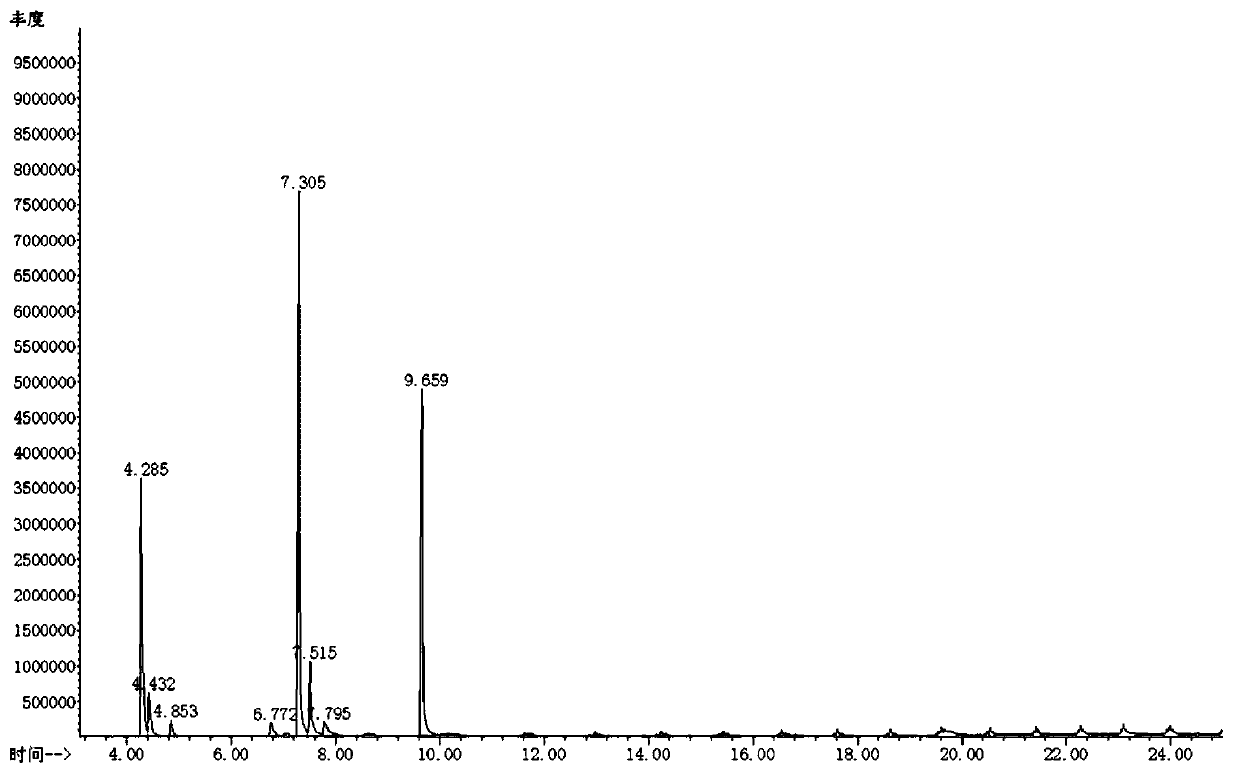

[0039] Prepare the loaded phosphotungstic acid HZSM-5 active agent by impregnation method, the loading of phosphotungstic acid (hereinafter referred to as PW) is 10%, that is, 10% PW / HZSM-5, and the loaded PW is Dawson structure; TiC and SiC The powder is mixed to make a composite wave absorbing agent with a mass ratio of 0.3:1; the active agent and wave absorbing agent are mixed at a ratio of 0.8:1 to make a microwave-induced catalyst; the prepared catalyst and biomass particles (from agricultural and forestry straw) After mixing evenly, put it into the microwave reactor. The average particle size of biomass particles is 1.5mm, the mass ratio of catalyst to biomass is 0.4:1, the microwave power is adjusted to 500W, the vacuum pressure is 20kPa, and the reaction time is 4min. The product bio-oil was obtained after full condensation and cooling temperature of -5°C under the suction of the reactor; the solid residue mixture in the reactor was washed with distilled water for 8 min...

Embodiment 3

[0046] Prepare the loaded phosphotungstic acid HZSM-5 active agent by impregnation method, the loading of phosphotungstic acid (hereinafter referred to as PW) is 15%, that is, 15% PW / HZSM-5, and the loaded PW is Dawson structure; TiC and SiC The powder is mixed to make a composite wave absorbing agent with a mass ratio of 0.4:1; the active agent and wave absorbing agent are mixed at a ratio of 1:1 to make a microwave-induced catalyst; the prepared catalyst and biomass particles (from agricultural and forestry straw) After mixing evenly, put it into the microwave reactor. The average particle size of biomass particles is 3mm, the mass ratio of catalyst to biomass is 0.5:1, the microwave power is adjusted to 600W, the vacuum pressure is 30kPa, and the reaction time is 5min. Under suction, after sufficient condensation, the cooling temperature is -10°C, and the product bio-oil is obtained; the solid residual mixture in the reactor is washed with distilled water for 10 minutes, cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com