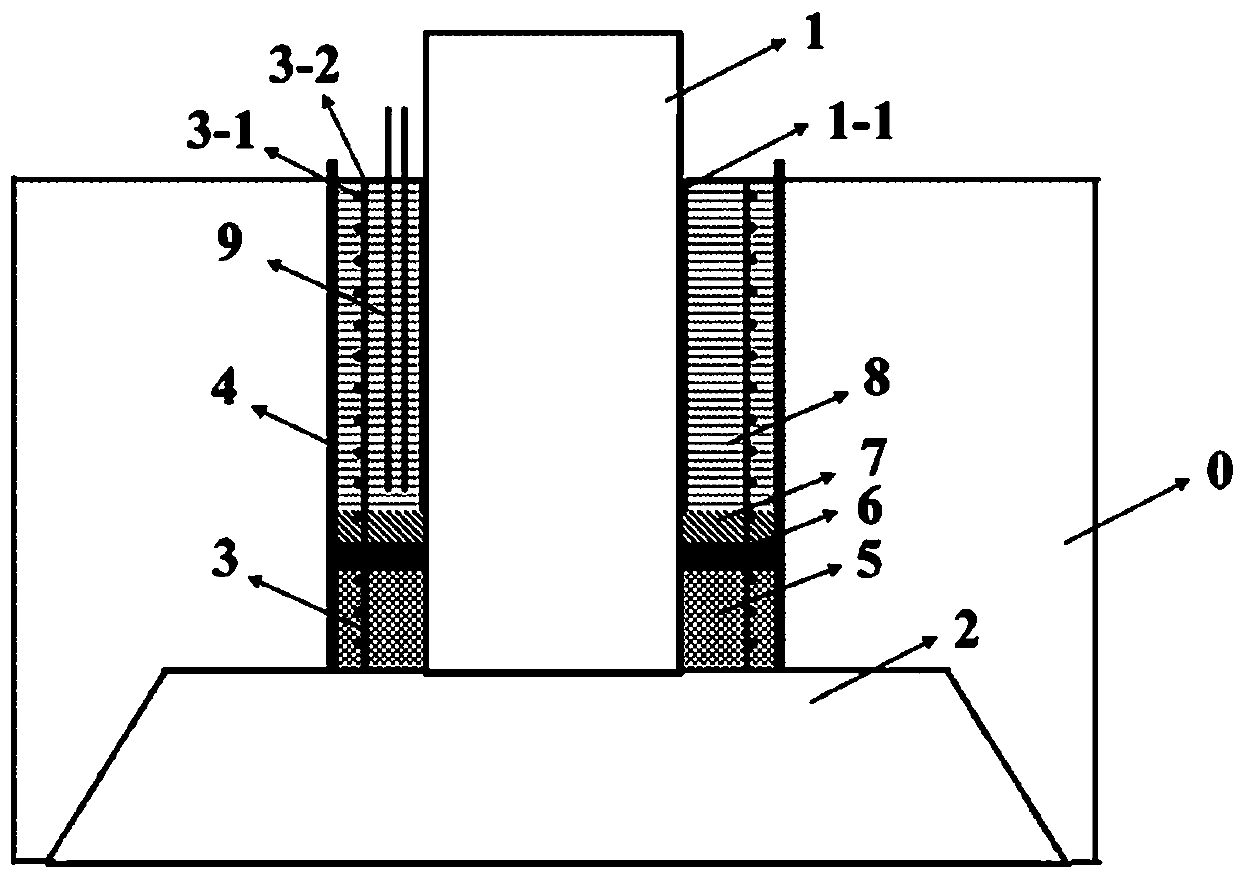

Method for reinforcing underwater concrete structure by ultrahigh-performance concrete

An underwater concrete and concrete reinforcement technology, which is applied in the repair of infrastructure, infrastructure engineering, construction, etc., can solve the problems of unsatisfactory reinforcement effect, high construction cost, and long construction period, so as to improve the underwater anti-dispersion ability , eliminating the need for planting bars, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, a kind of ultra-high-performance concrete that strengthens underwater concrete structure, by cement (42.5 grade Portland cement) 100, slag powder (S105 grade) 25, fly ash 15, silica fume 15, quartz sand 55, Quartz powder 36, limestone powder 25, steel fiber (length 18mm, diameter 0.25mm hook-end steel fiber) 17.8, viscosity regulator (hydroxypropyl methyl cellulose ether with a viscosity value of 8000MPa s) 0.06, water reducing The weight ratio of agent (powder) 1.5, defoamer (powder) 0.2 and water 27 weighs the raw materials respectively, and then cement, mineral powder, fly ash, silica fume, quartz sand, quartz powder, limestone powder, viscosity The conditioner, water reducer, and defoamer are added to the forced mixer for pre-mixing, and then water is added to the mixing pot at one time and continued to stir. When the mixture is in a uniform flow state, steel fibers are added and mixed. In the mixture, continue to stir until the mixture is uniform to o...

Embodiment 2

[0059] Embodiment 2, a kind of ultra-high-performance concrete that strengthens underwater concrete structure, according to cement (52.5 grade Portland cement) 100, slag powder (S95 grade) 40, fly ash 17, silica fume 32, quartz sand 75, Quartz powder 50, limestone powder 30, steel fiber (long straight steel fiber with a length of 19 mm and a diameter of 0.22 mm) 30.5, viscosity regulator (hydroxypropyl methyl cellulose ether with a viscosity value of 8000 MPa s) 0.11, water reducing The weight ratio of agent (liquid) 2.0, defoamer (liquid) 0.3 and water 36 is respectively weighed raw materials, and then cement, mineral powder, fly ash, silica fume, quartz sand, quartz powder, limestone powder and viscosity modifier Add them together to the forced mixer for pre-mixing, then add the water mixed with water reducing agent and defoamer into the mixing pot at one time and continue stirring. When the mixture is in a uniform flow state, add steel fiber and mix. In the mixture, continu...

Embodiment 3

[0060] Embodiment 3, a kind of ultra-high-performance concrete that strengthens underwater concrete structure, according to cement (52.5 grade ordinary Portland cement) 100, mineral powder (S95 grade) 50, fly ash 20, silica fume 40, quartz sand 90 , quartz powder 60, limestone powder 44, steel fiber (long straight steel fiber with length 16mm, diameter 0.18mm and end hook steel fiber with length 16mm, diameter 0.20mm are used in a weight ratio of 4:6) 38.5, viscosity Regulator (hydroxypropyl methyl cellulose ether with a viscosity value of 40000MPa s) 0.16, water reducer (liquid) 2.4, defoamer (liquid) 0.4 and water 39 weight ratio Weigh raw materials respectively, and then cement , slag powder, fly ash, silica fume, quartz sand, quartz powder, limestone powder and viscosity regulator are added to the forced mixer for pre-mixing, and then the water mixed with water reducer and defoamer is added at one time Stir in the pot and continue to stir. When the mixture is in a uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com