Automotive headlight lens, production line and manufacturing method

A lamp lens and production line technology, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of difficult production and low yield, and achieve the effects of saving raw materials, easy processing, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

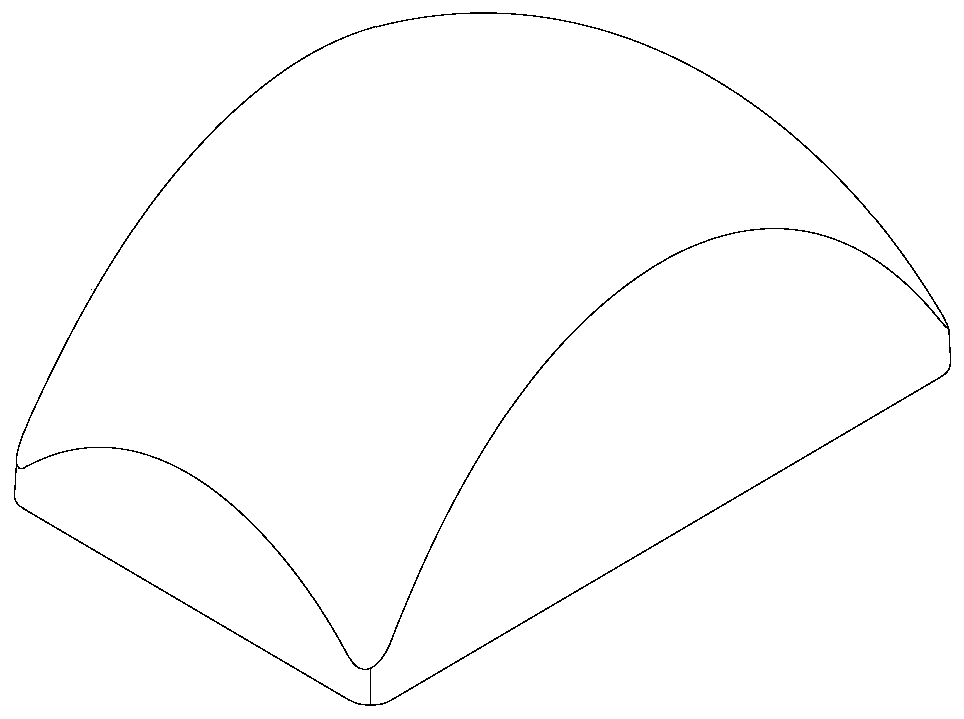

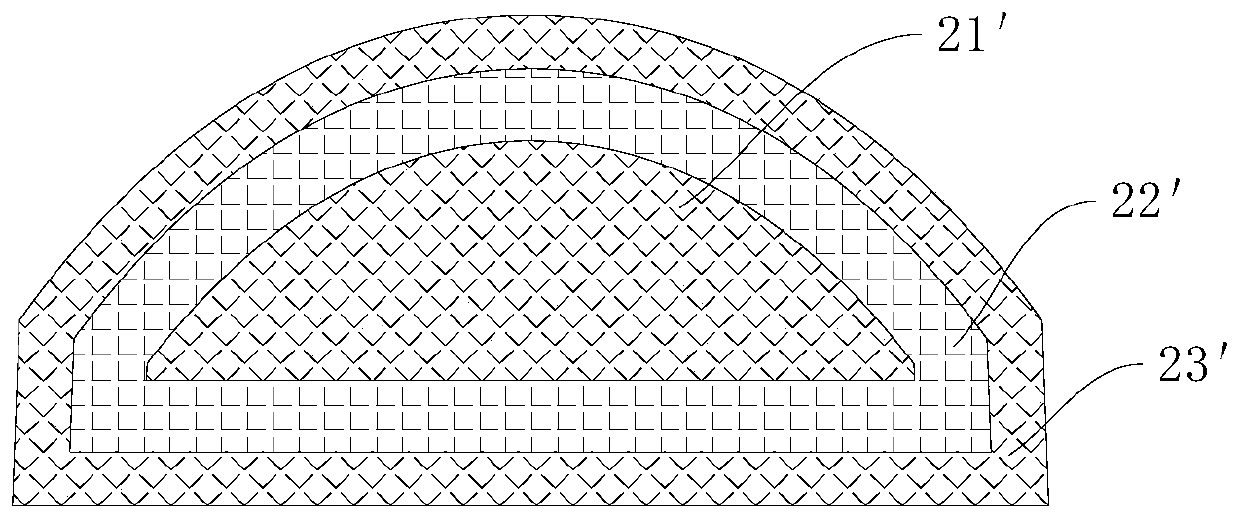

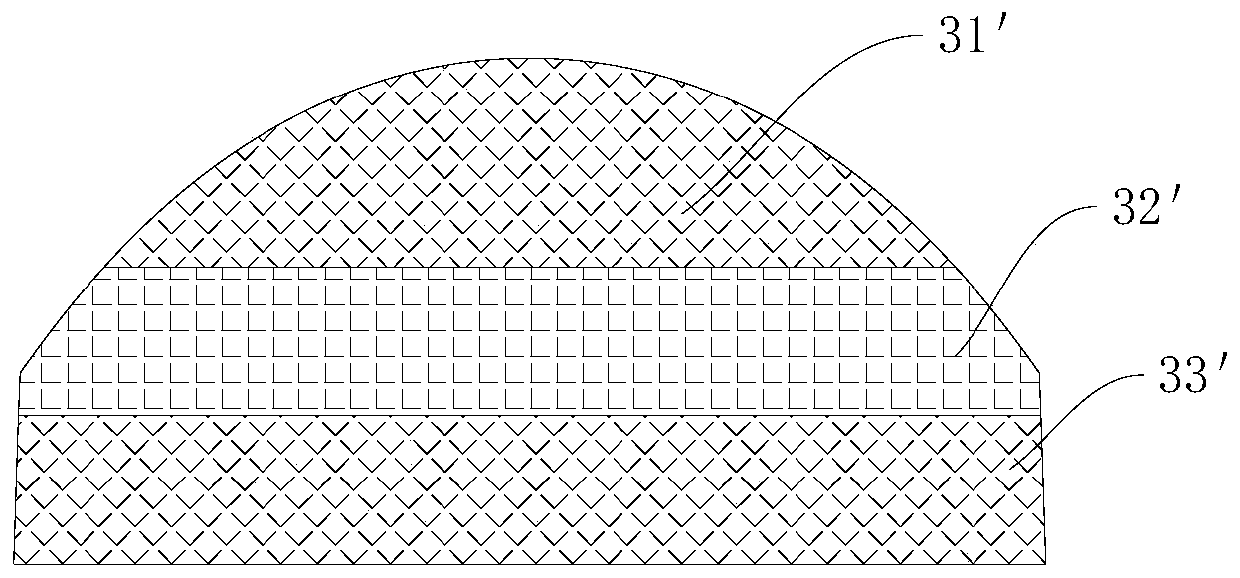

[0070] Further, as a specific embodiment of the manufacturing method of the automobile headlight lens provided by the present invention, the step of pressure forming the curved mirror 12 includes:

[0071] Utilize the thermoforming device 22 to preform the curved mirror 12 on the plastic plate, and carry out the shaping process to the inner surface and the outer surface of the curved mirror 12; the curved mirror 12 of plastic material is formed in the process of preforming, and then the shaping process During the process, the inner surface and outer surface of the curved mirror 12 are finalized to ensure the shape and size of the inner and outer surfaces of the curved mirror 12. The process is simple, and it is beneficial to improve the light shape control ability of the automotive headlight lens 100 product.

[0072] The manufacturing method of the automobile headlight lens provided by the present invention is suitable for producing the automobile headlight lens 100 of any of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com