A Coal Quality Parameter Control Method to Ensure Safe Operation of Zhundong Coal Boiler

A technology of safe operation and parameter control, which is applied in the direction of controlling combustion, lighting and heating equipment, fuel, etc., and can solve problems such as lack of clear regulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

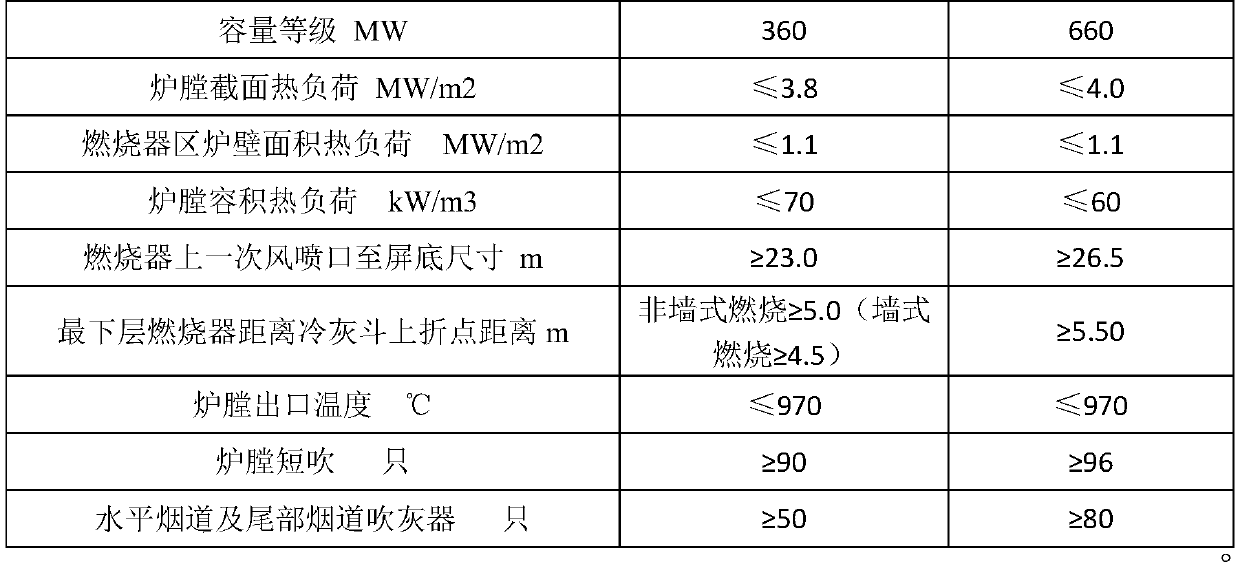

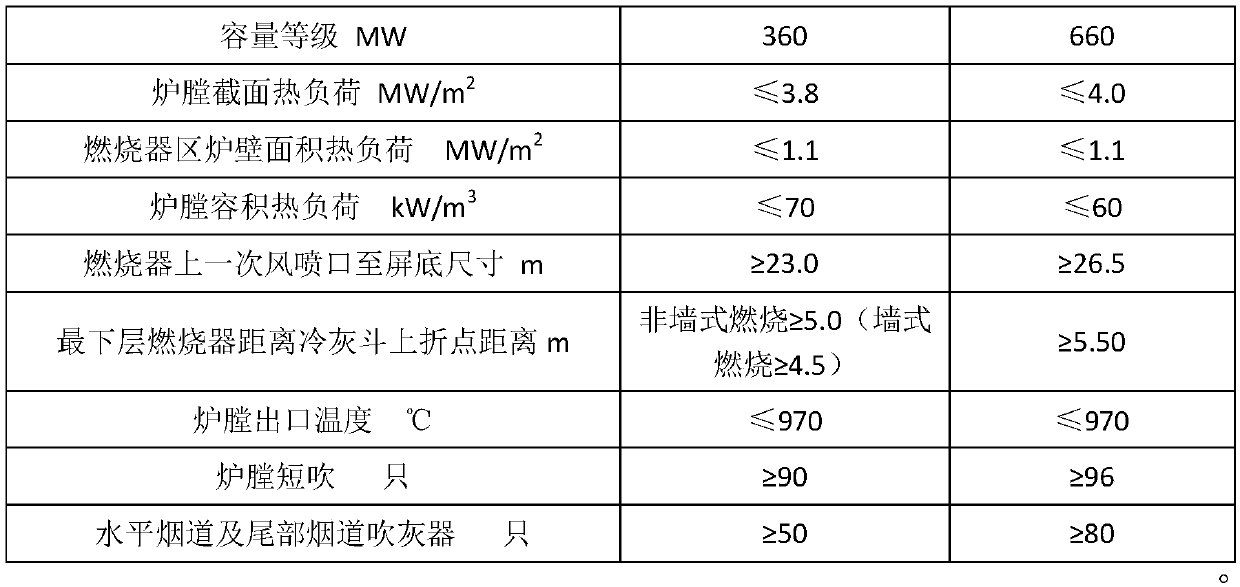

[0037] Example 1: Whether 100% Tianchi energy coal can be fully burned on the newly designed Zhundong coal boilers with capacity levels of 360MW and 660MW

[0038] Step 1: Calculate the ash content of the coal blended into the furnace by calculating the ash content, ash component content and mass ratio of the blended coal, or test the blended coal according to GB / T1574-2007 coal ash composition analysis method ash content. The ash component specifically includes SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O and TiO 2 .

[0039] In this embodiment, according to the GB / T1574-2007 coal ash component analysis method, the ash component index of the coal mixed into the furnace is tested, specifically including (SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O, TiO 2 );

[0040] In this example, the furnace coal is a single coal type of Tianchi Energy Coal, and the test results of its ash content are as follows:

[0041] SiO 21 =13.54%, Al 2 o 31 =14.7...

Embodiment 2

[0062] Example 2: Whether 90% Tianchi Energy Coal + 10% Alkaline Ditch Coal can be fully burned on the newly designed Zhundong Coal boilers with capacity levels of 360MW and 660MW

[0063] Step 1: Calculate the ash content of the coal blended into the furnace by calculating the ash content, ash component content and mass ratio of the blended coal, or test the blended coal according to GB / T1574-2007 coal ash composition analysis method ash content. The ash component specifically includes SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O and TiO 2 .

[0064] Among them, the calculation method of different ash content of coal blended into the furnace is as follows:

[0065] HY=(R 1 *Y 1 *A ar1 +R 2 *Y 2 *A ar2 +.. . . +R i *Y i *A ari ) / (R 1 *A ar1 +R 2 *A ar2 +.. . . +R i *A ari )

[0066] Among them: HY represents the SiO of mixed coal 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O and TiO 2 The content of a certain ash component in t...

Embodiment 90

[0102] For present embodiment 90% mass ratio Tianchi Energy Coal+10% mass ratio the ash composition of the furnace mixed coal of alkali ditch coal and relevant index meet aforementioned (1) (2) (3) (4) (5) (6) All six, therefore meet the safe combustion requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com