Tea leaf processing device

A processing device and tea technology, applied in the direction of air heater, fluid heater, drying gas arrangement, etc., can solve the problems of high production cost, large energy consumption, low heat, etc., achieve reduced processing cost, controllable hot air temperature, Good for heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

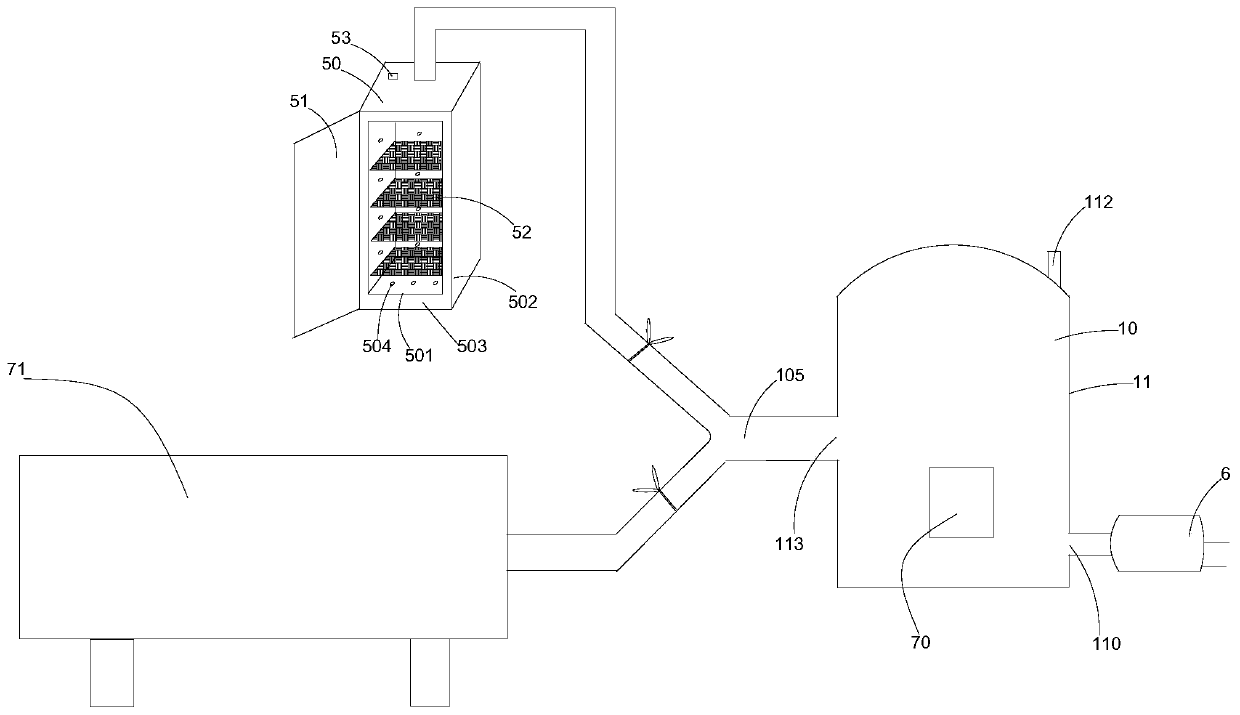

[0043] see Figure 1-Figure 6 .

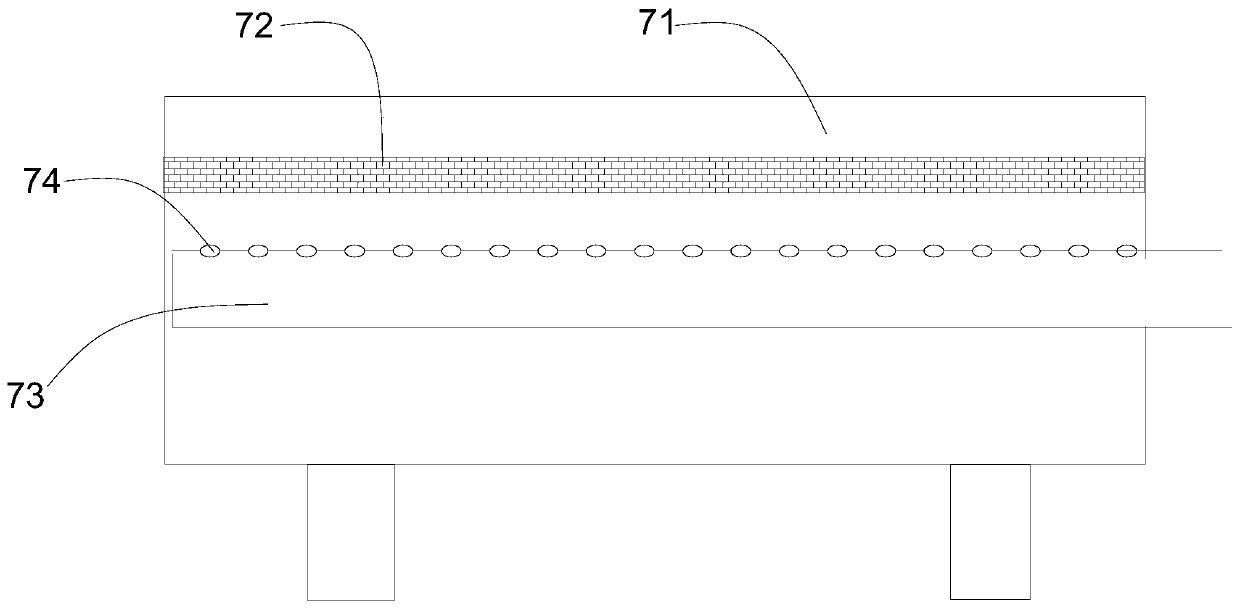

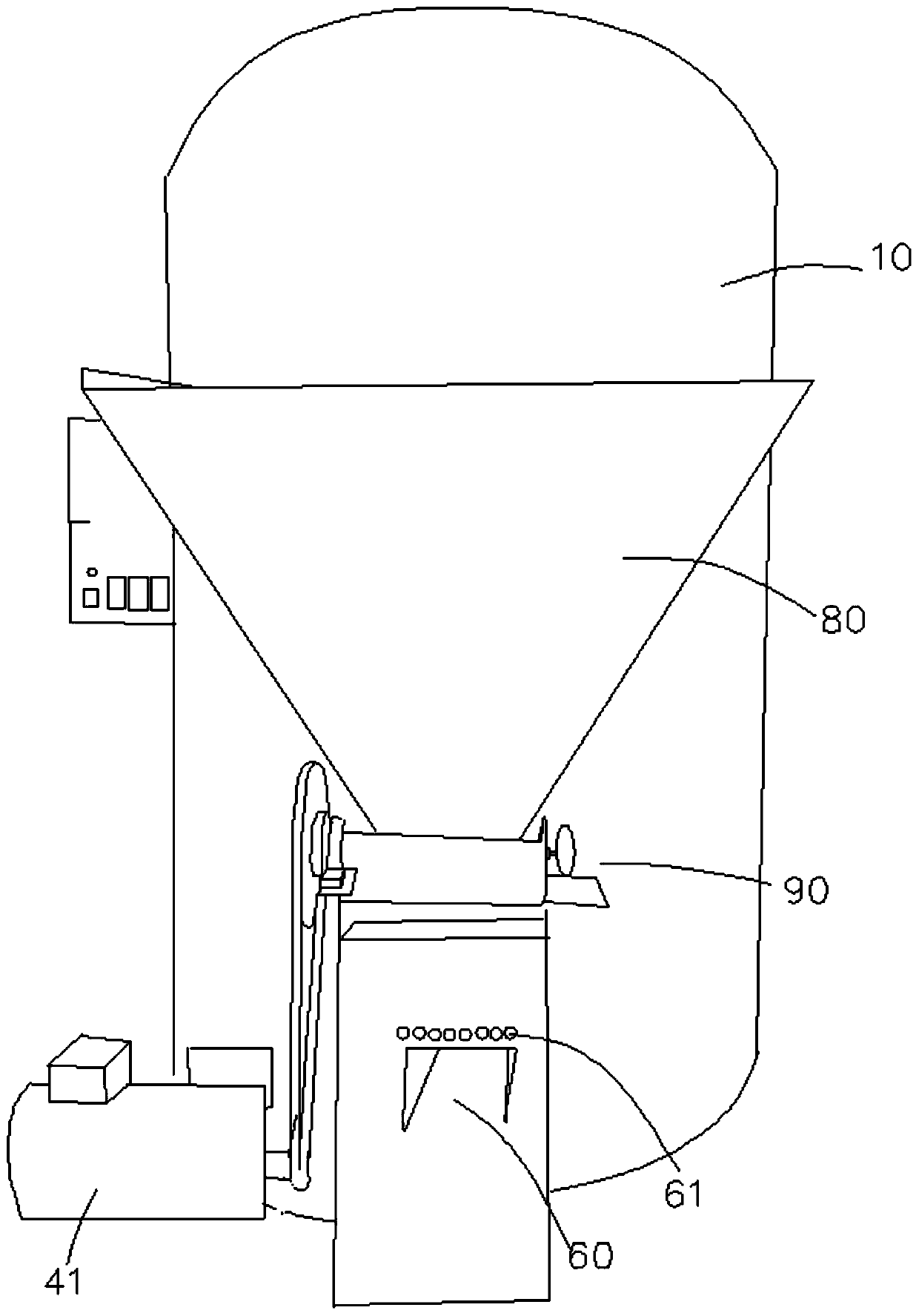

[0044] A tea processing device, comprising: a boiler, a gas pipeline 105, and a withering tank. The boiler consists of a main body 10, a shell 11, a cold air inlet 110, a cold air chamber, a hot air outlet 113, an exhaust gas outlet 112, and a combustion chamber 70. One end of the cold air chamber is It is connected to the cold air inlet 110 and the other end is connected to the hot air outlet 113. The cold air chamber is heated by the main body 10 in the casing, the combustion chamber 70 is arranged in the boiler main body 10 and communicates with the air, and the exhaust gas outlet 112 is used to discharge the exhaust gas generated by the combustion chamber 70; The tank includes a tank body 71, a tea storage layer 72, and a tank body air distribution pipe 73. Between; one end of the gas pipeline 105 is connected to the hot gas outlet 113, and the other end is connected to the tank air distribution pipe 73.

[0045] It also includes a fragr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com