Position sensorless control method and device for long-line driving permanent magnet motor

一种永磁电机、长线驱动的技术,应用在交流电动机控制、电子换向电动机控制、电流控制器等方向,能够解决得不到转子位置信号等问题,达到减少系统体积、提高检测精度、扩大调速范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

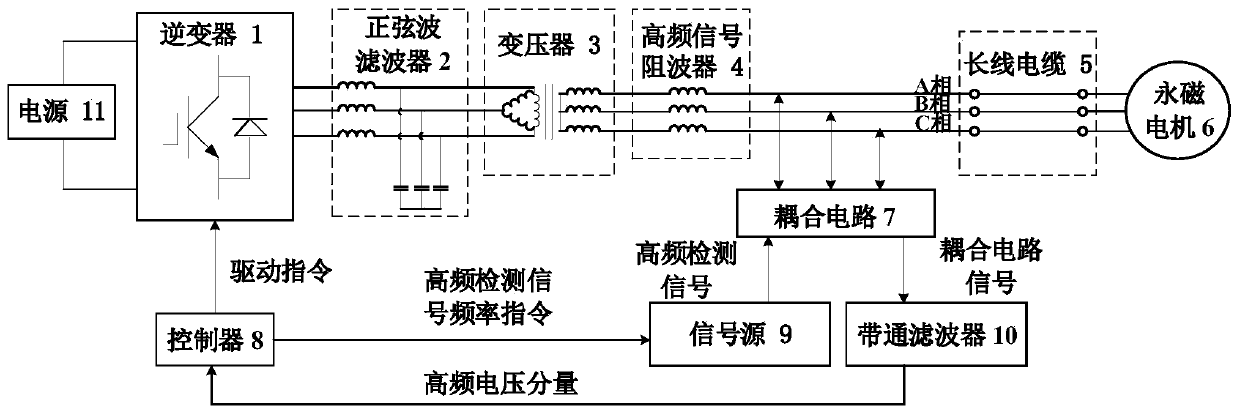

[0038] The position sensorless control method and device for long-line drive permanent magnet motors of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

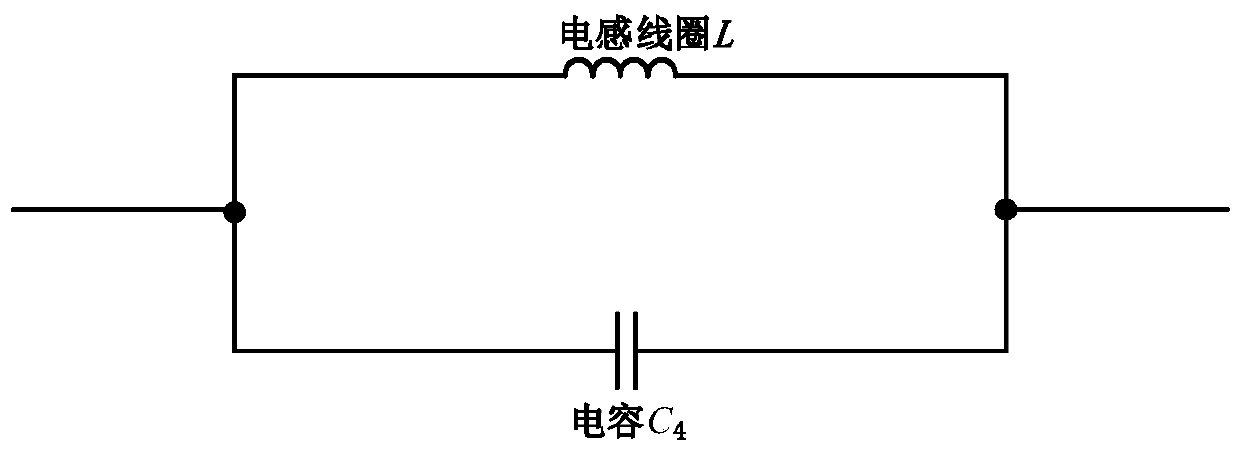

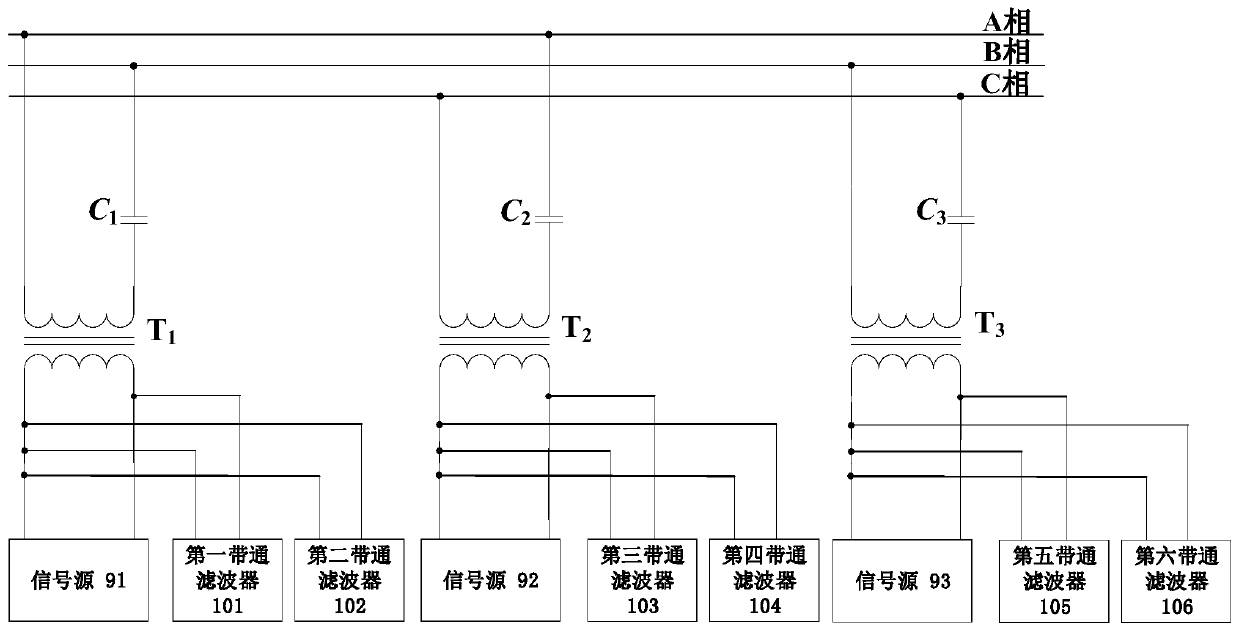

[0039] The position sensorless control method for long-line drive permanent magnet motors of the present invention is to add a coupling circuit behind the transformer in the long-line drive circuit of the permanent magnet motor, and pass high-frequency detection signals of three different frequencies through three of the coupling circuits respectively. A transformer is coupled into the motor power line and winding, and then the high-frequency voltage components on the primary side of the three transformers are obtained through a band-pass filter, and the position signal is obtained according to the effective value of the high-frequency voltage component. Sensorless control of motors.

[0040] The high-frequency detection signal is generated by an indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com