Textile wastewater recycling method and device

A technology of textile wastewater and suspension device, applied in textile industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of reducing the cost of wastewater treatment, expanding the scope of effective utilization, and improving the efficiency of wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

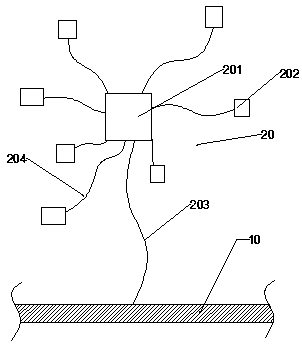

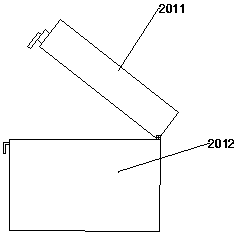

Method used

Image

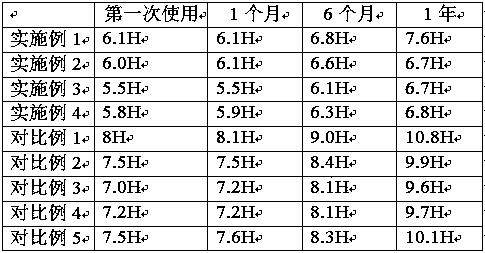

Examples

Embodiment 1

[0040] A method for recycling textile waste water, comprising the steps of:

[0041] S1: Textile wastewater is pre-treated to obtain pre-treated water;

[0042] The pre-treatment includes sequential mechanical filtration and pre-treatment agent treatment and filtration; mechanical filtration adopts a grid;

[0043] S2: The pre-treated water is sent to the adjustment tank to adjust the pH to 4;

[0044] S3: enter the MBR reaction tank for treatment, and obtain water that meets the discharge standard.

[0045] The pretreatment agent comprises 30 parts of activated carbon, 20 parts of modified bagasse, 30 parts of adsorption polymer, 12 parts of bamboo powder with a particle diameter of 800-1000 microns, and 5 parts of acrylate.

[0046] The adsorption polymer is formed by using styrene and acrylate as monomers, adding divinylbenzene as a crosslinking agent, and toluene as a porogen.

[0047] The pretreatment agent is prepared by the following steps:

[0048] (1) Activated ca...

Embodiment 2

[0052] A method for recycling textile waste water, comprising the steps of:

[0053] S1: Textile wastewater is pre-treated to obtain pre-treated water;

[0054] The pre-treatment includes sequential mechanical filtration and pre-treatment agent treatment and filtration; mechanical filtration adopts a grid;

[0055] S2: The pre-treated water is sent to the adjustment tank to adjust the pH;

[0056] S3: enter the MBR reaction tank for treatment, and obtain water that meets the discharge standard.

[0057] The pretreatment agent includes 22 parts of activated carbon, 25 parts of modified bagasse, 20 parts of adsorption polymer, 20 parts of bamboo powder with a particle diameter of 800-1000 microns, and 8 parts of acrylate.

[0058] The adsorption polymer is formed by using styrene and acrylate as monomers, adding divinylbenzene as a crosslinking agent, and toluene as a porogen. Specific method: add acrylate monomer, styrene monomer, cross-linking agent and porogen to the aqueo...

Embodiment 3

[0065] A method for recycling textile waste water, comprising the steps of:

[0066] S1: Textile wastewater is pre-treated to obtain pre-treated water;

[0067] The pre-treatment includes sequential mechanical filtration and pre-treatment agent treatment and filtration; mechanical filtration adopts a grid;

[0068] S2: The pre-treated water is sent to the adjustment tank to adjust the pH;

[0069] S3: enter the MBR reaction tank for treatment, and obtain water that meets the discharge standard.

[0070] The pretreatment agent includes 25 parts of activated carbon, 25 parts of modified bagasse, 25 parts of adsorption polymer, 18 parts of bamboo powder with a particle diameter of 800-900 microns, and 3 parts of acrylate.

[0071] The adsorption polymer is formed by using styrene and acrylate as monomers, adding divinylbenzene as a crosslinking agent, and toluene as a porogen.

[0072] The pretreatment agent is prepared by the following steps:

[0073] (1) Activated carbon is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com