A kind of preparation method of chitosan quaternary ammonium salt-fatty acid vesicle

A chitosan quaternary ammonium salt, fatty acid technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of limited application, low stability, narrow pH range, etc., to ensure effective supply and enhance system stability. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of chitosan quaternary ammonium salt solution: Dissolve chitosan quaternary ammonium salt (2-hydroxypropyltrimethylammonium chloride chitosan) in water, stir at room temperature, and prepare a sugar unit of 20mmol / The chitosan quaternary ammonium salt solution of L is standby;

[0029] 2) Preparation of sodium oleate solution: add an appropriate amount of oleic acid into 30mmol / L NaOH solution, stir at room temperature for 30min, and prepare 20mmol / L sodium oleate solution for later use;

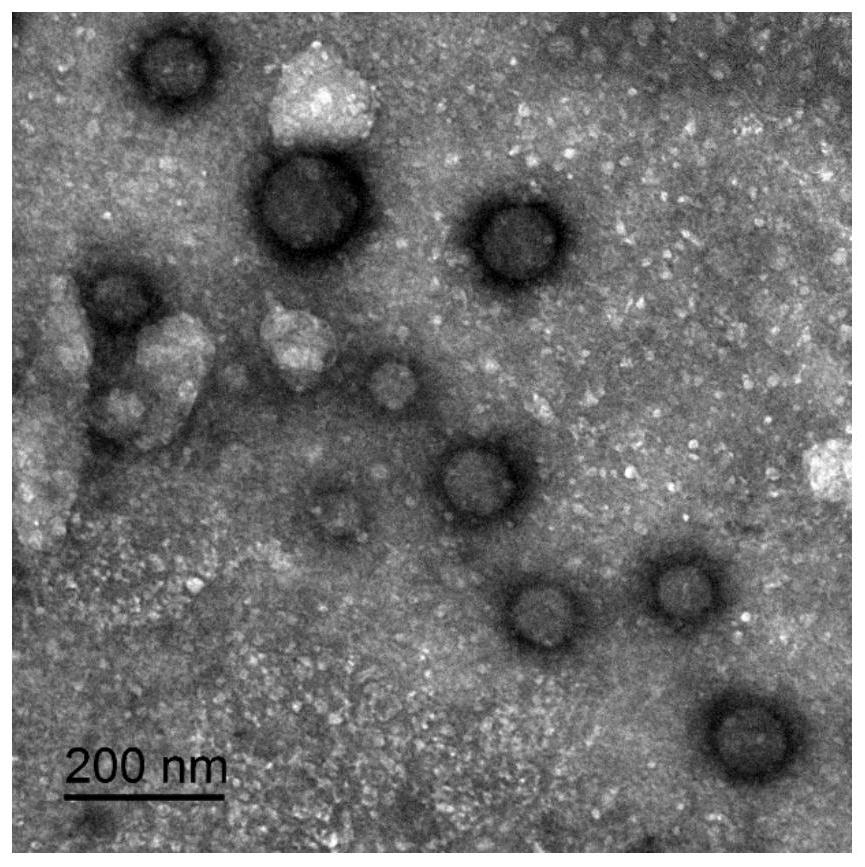

[0030] 3) Preparation of composite vesicles: Dilute the chitosan quaternary ammonium salt solution with a sugar unit concentration of 20mmol / L to 10mmol / L with water, then dilute the 20mmol / L sodium oleate solution to 5mmol / L, at 20°C , adding an equal volume of sodium oleate solution dropwise to the chitosan quaternary ammonium salt solution, and stirring slowly at 60 rpm to obtain a composite vesicle solution;

[0031] 4) pH adjustment of the vesicle solution: adjus...

Embodiment 2

[0033] 1) Preparation of chitosan quaternary ammonium salt solution: Dissolve chitosan quaternary ammonium salt (2-hydroxypropyltrimethylammonium chloride chitosan) in water, stir at room temperature, and prepare a sugar unit of 20mmol / The chitosan quaternary ammonium salt solution of L is standby;

[0034] 2) Preparation of sodium oleate solution: add an appropriate amount of oleic acid into 30mmol / L NaOH solution, stir at room temperature for 30min, and prepare 20mmol / L sodium oleate solution for later use;

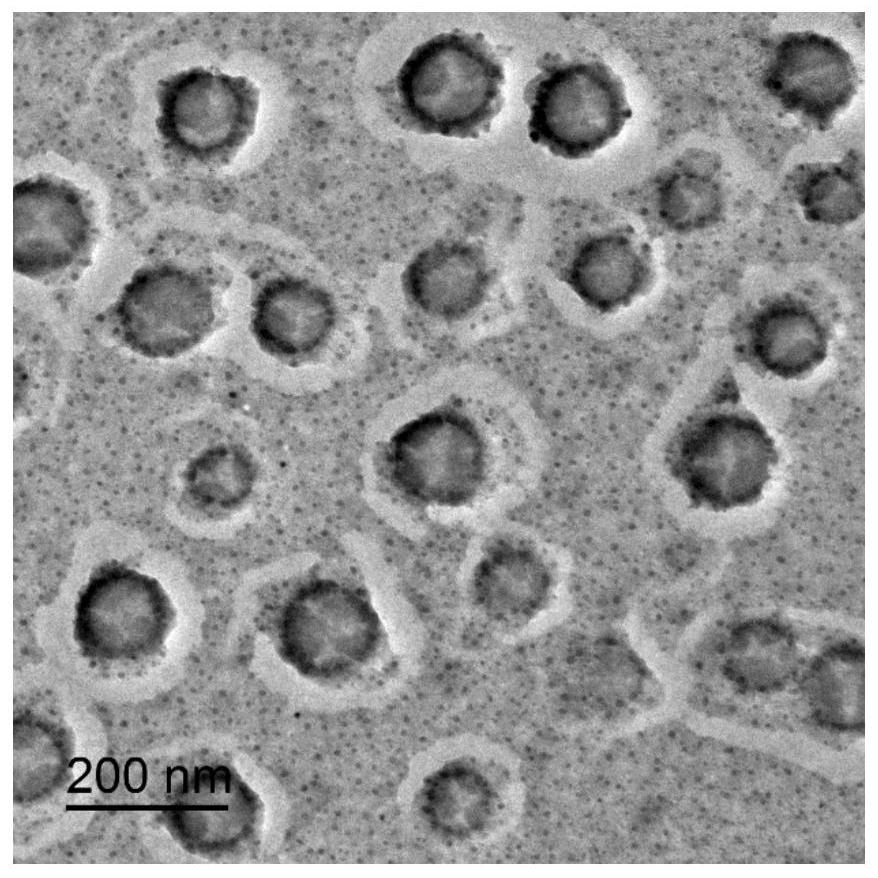

[0035] 3) Preparation of composite vesicles: dilute 20mmol / L sodium oleate solution to 16mmol / L, do not dilute chitosan quaternary ammonium salt solution, add an equal volume of sodium oleate solution dropwise to chitosan at 40°C In the sugar quaternary ammonium salt solution, stir slowly at 80rpm to prepare the composite vesicle solution;

[0036] 4) pH adjustment of the vesicle solution: adjust the pH of the vesicle solution with 0.5mol / L hydrochloric acid solution,...

Embodiment 3

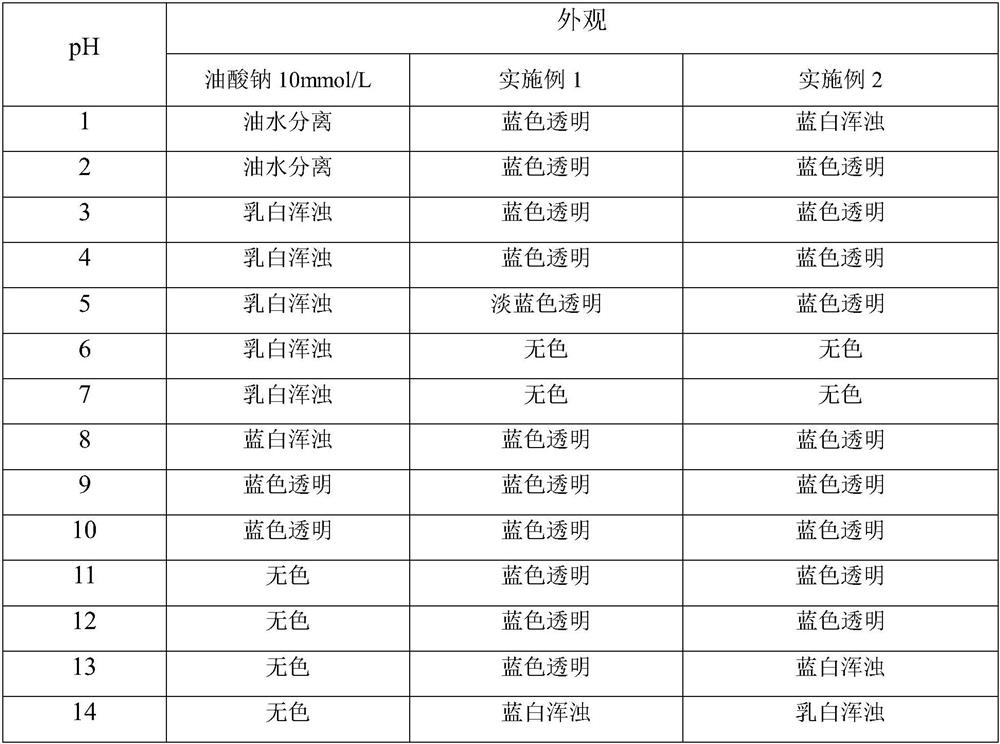

[0038] In order to investigate the stability of the vesicles, add 0.5mol / L hydrochloric acid or sodium hydroxide to the vesicle fluid prepared in Example 1 and Example 2 and the comparative sample sodium oleate (10mmol / L, pH=9) , adjust the pH of the solution, and visually observe the appearance of the solution, the results are shown in Table 1.

[0039] Table 1. Appearance of sample solution at different pH

[0040]

[0041] It can be seen from Table 1 that for the sodium oleate system, only when the pH is 8 to 10, the solution has the unique blue color of the vesicles; while for the sodium oleate-chitosan quaternary ammonium salt system, when the pH is 1 At ~5 and 8~13, the solutions all showed the blue color characteristic of vesicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com