Aerogel insulating putty, and processing method and construction method thereof

A construction method, aerogel technology, applied in filling slurry, covering/lining, construction, etc., can solve the problems of thick, poor thermal insulation performance of the thermal insulation layer, etc., achieve good gloss, excellent decorative performance, insulation heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

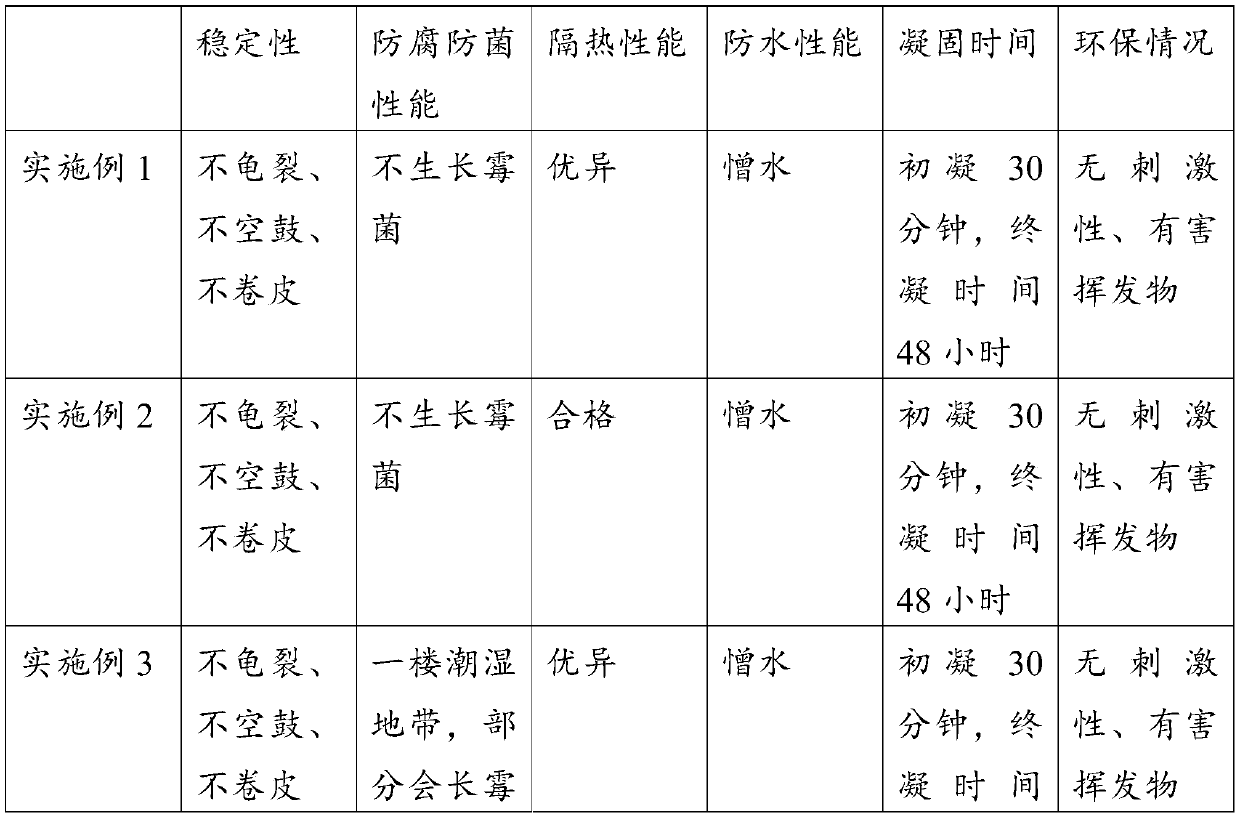

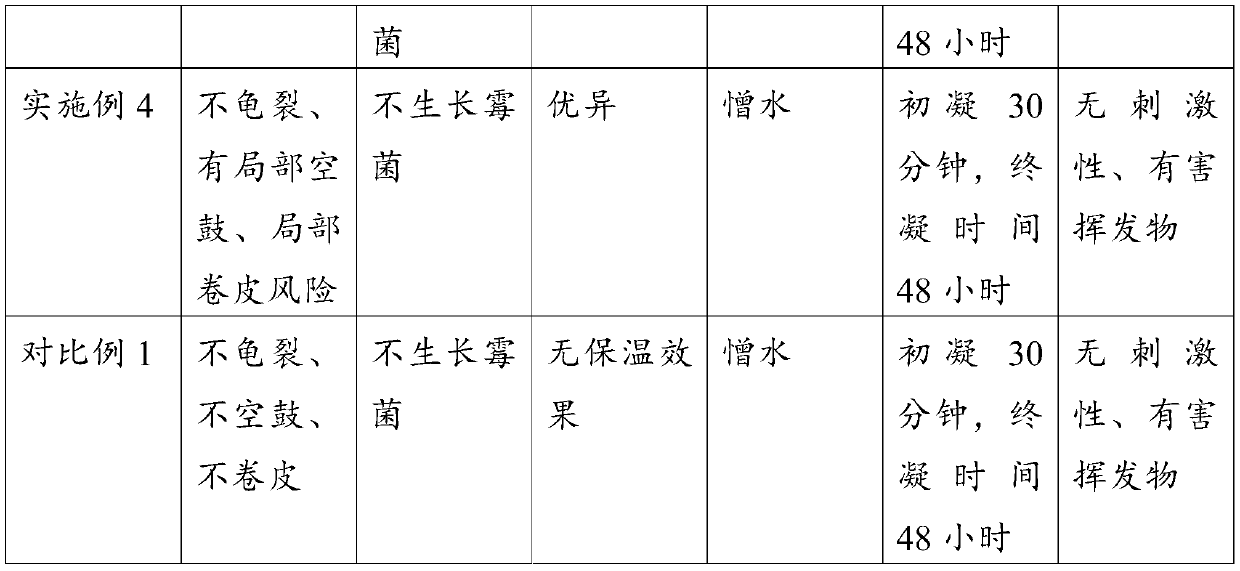

Examples

Embodiment 1

[0069] Embodiment 1: Weigh batching water 30.8%, propylene glycol 4%, construction preservative 0.2%, titanium dioxide 6%, aerogel 4% and pure acrylic emulsion 55% by weight;

[0070] Add water, propylene glycol, construction preservatives and titanium dioxide in sequence;

[0071] Control the rotation speed at 500-700r / h, and carry out 25-30min stirring and beating

[0072] After beating, add airgel and pure acrylic emulsion in sequence and stir for 5-10 minutes until uniformly mixed.

Embodiment 2

[0073] Example 2: In this example, compared with Example 1, water, propylene glycol, construction preservatives and titanium dioxide are added all at once in different order before beating, and airgel and pure acrylic emulsion are added in one time out of order after beating Added, the rest of the conditional parameters remain unchanged.

Embodiment 3

[0074] Embodiment 3: Compared with Embodiment 1, this embodiment has discarded the preservative for construction, and all the other condition parameters are constant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com