Double-layered water and tidal drainage device of sectional combined floor drain and construction method

A segmented, double-drainage technology, applied to water supply devices, drainage structures, waterway systems, etc., can solve the problems of troublesome toilets in compartments, difficulty in achieving the perfect unity of aesthetics and functions, and achieve product quality that is easy to guarantee , good drainage effect and easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

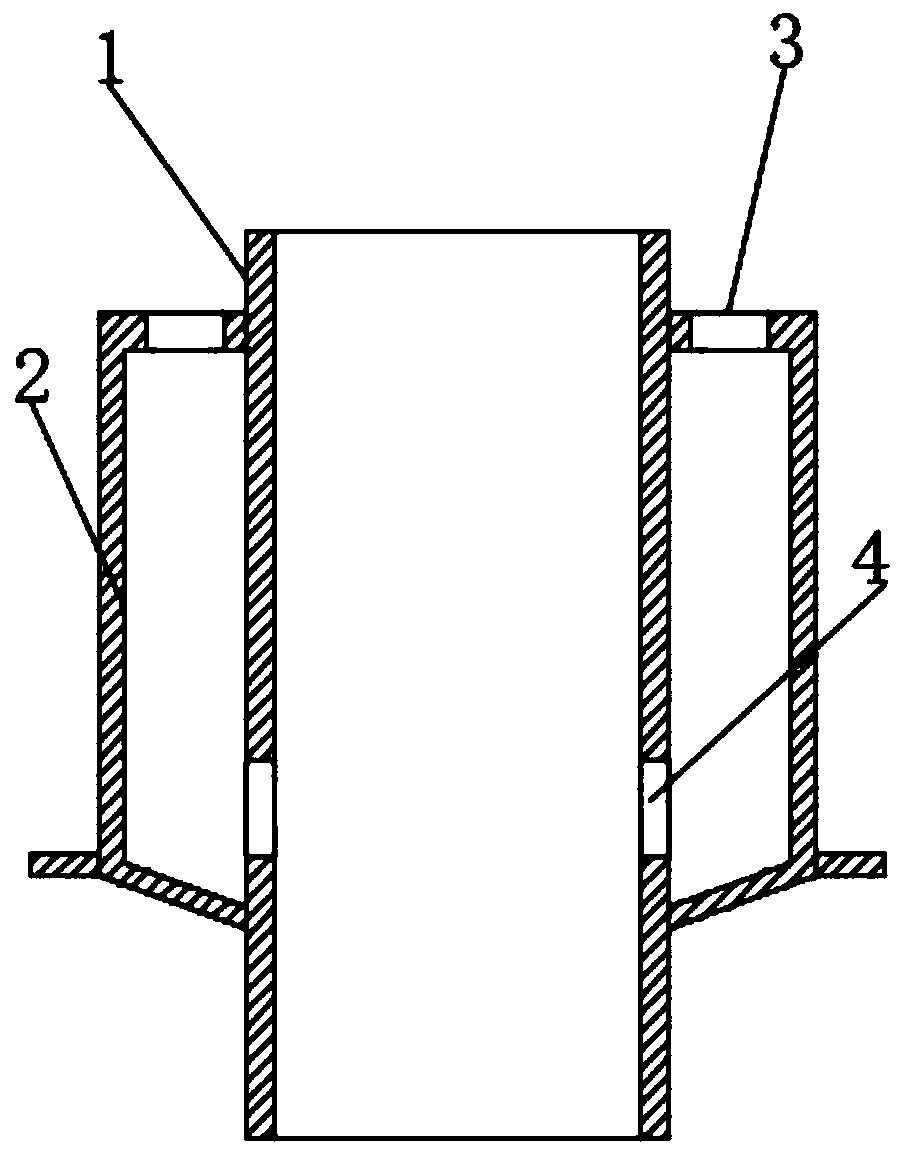

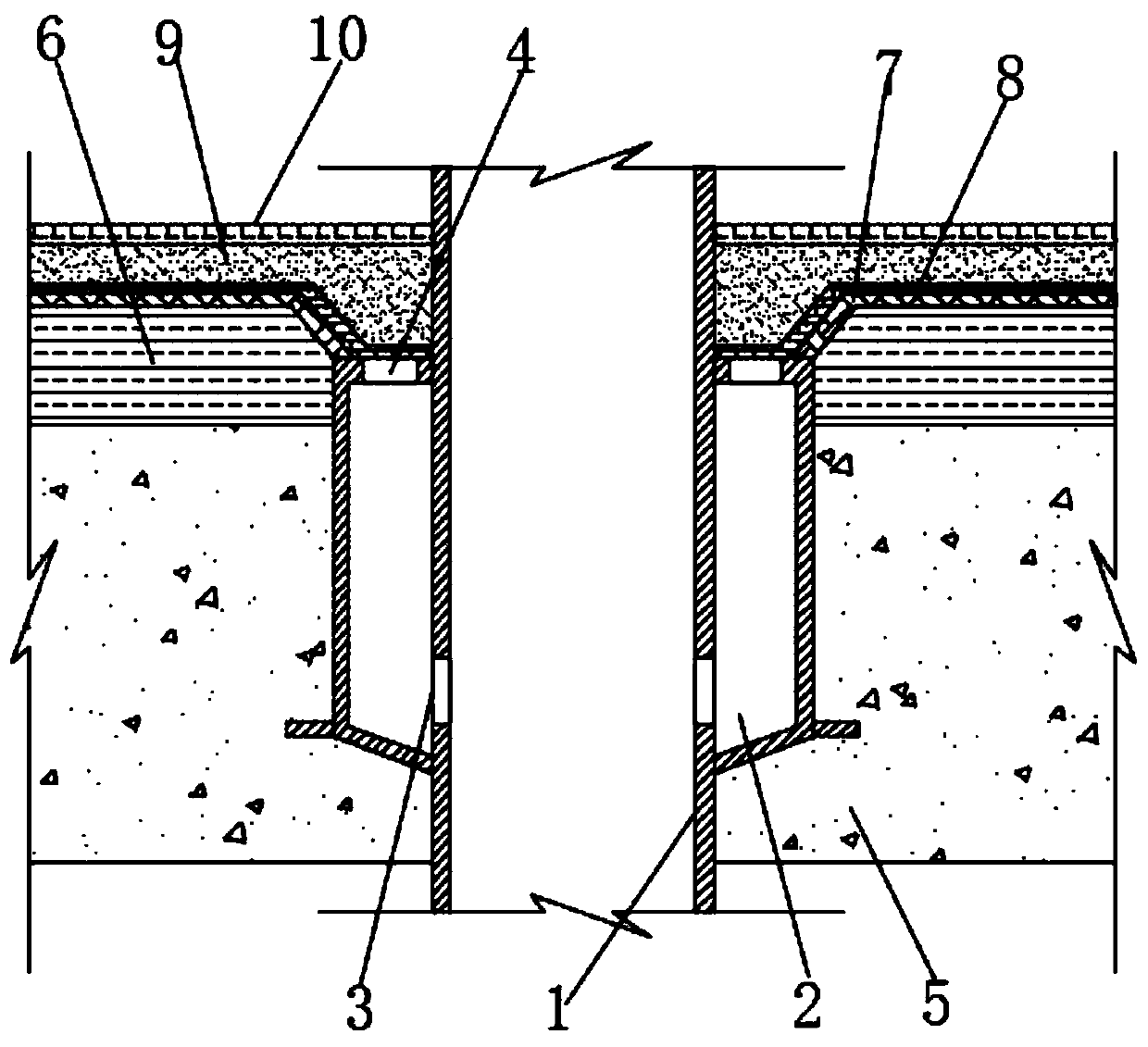

[0030] refer to figure 1, 2, 4, a segmented combined floor drain double-deck drainage and moisture removal device, including adjustable double drainage sleeves, adjustable double drainage sleeves include inner pipe 1 and outer pipe 2, the connection between inner pipe 1 and outer pipe 2 The space is bonded with a solvent-based adhesive through a plastic piping system. The inner tube 1 is provided with a plurality of first permeable holes 3, and the outer tube 2 is provided with a plurality of second permeable holes 4, and the plurality of second permeable holes 4 are close to the outer tube. The upper end of the pipe 2 is set, and the first reinforced concrete structure layer 5 is poured on both sides of the outer pipe 2. The upper end of the first reinforced concrete structure layer 5 is provided with a first fine stone concrete slope layer 6, and the first fine stone concrete slope The upper end of the layer 6 is provided with a first geotextile water-guiding layer 7, and th...

Embodiment 2

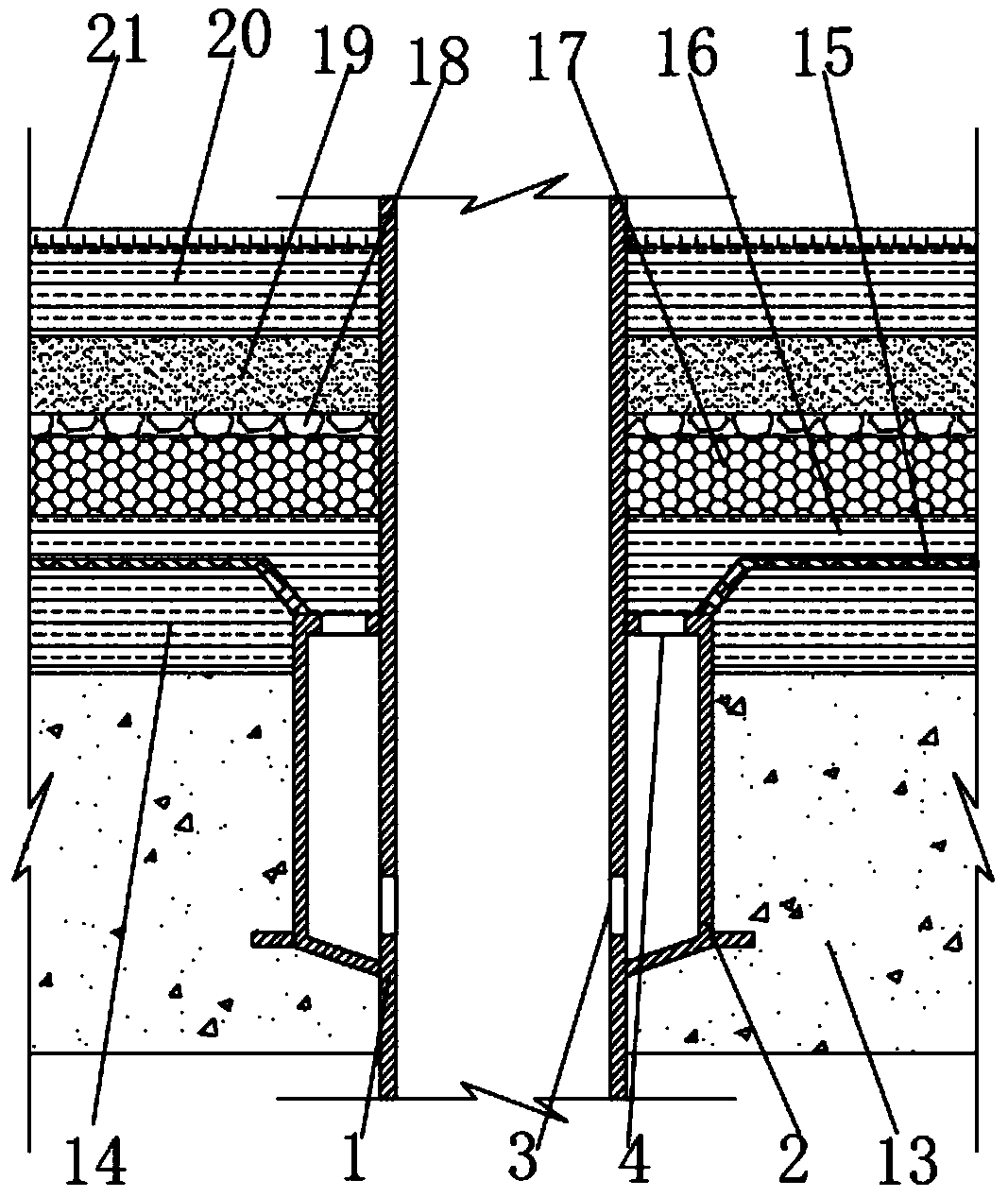

[0032] refer to figure 1 , 3, 4, a second reinforced concrete structure layer 13 is poured on both sides of the outer pipe 2, and the upper end of the second reinforced concrete structure layer 13 is provided with a second fine-stone concrete slope-finding layer 14, and the second fine-stone concrete slope-making layer The upper end of 14 is provided with the second waterproof layer 15, and the upper end of the second waterproof layer 15 is provided with the cement mortar protective layer 16, and the upper end of the cement mortar protective layer 16 is provided with the plastic drain board layer 17, and the upper end of the plastic drain board layer 17 is provided with The second geotextile aquifer 18, the upper end of the second geotextile aqueduct 18 is provided with a coarse sand transition layer 19, the upper end of the coarse sand transition layer 19 is provided with a second cement mortar bonding layer 20, the second cement mortar bonding layer The upper end of 20 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com