Novel VOCs disposal device based on RTO and RCO cooperative work, and working method thereof

A disposal device and collaborative work technology, applied in the field of new VOCs disposal devices, can solve the problems of heavy catalyst poisoning, small buffer tank capacity, and vent exhaust pipe explosion, etc., to achieve high thermal energy utilization, small footprint, and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

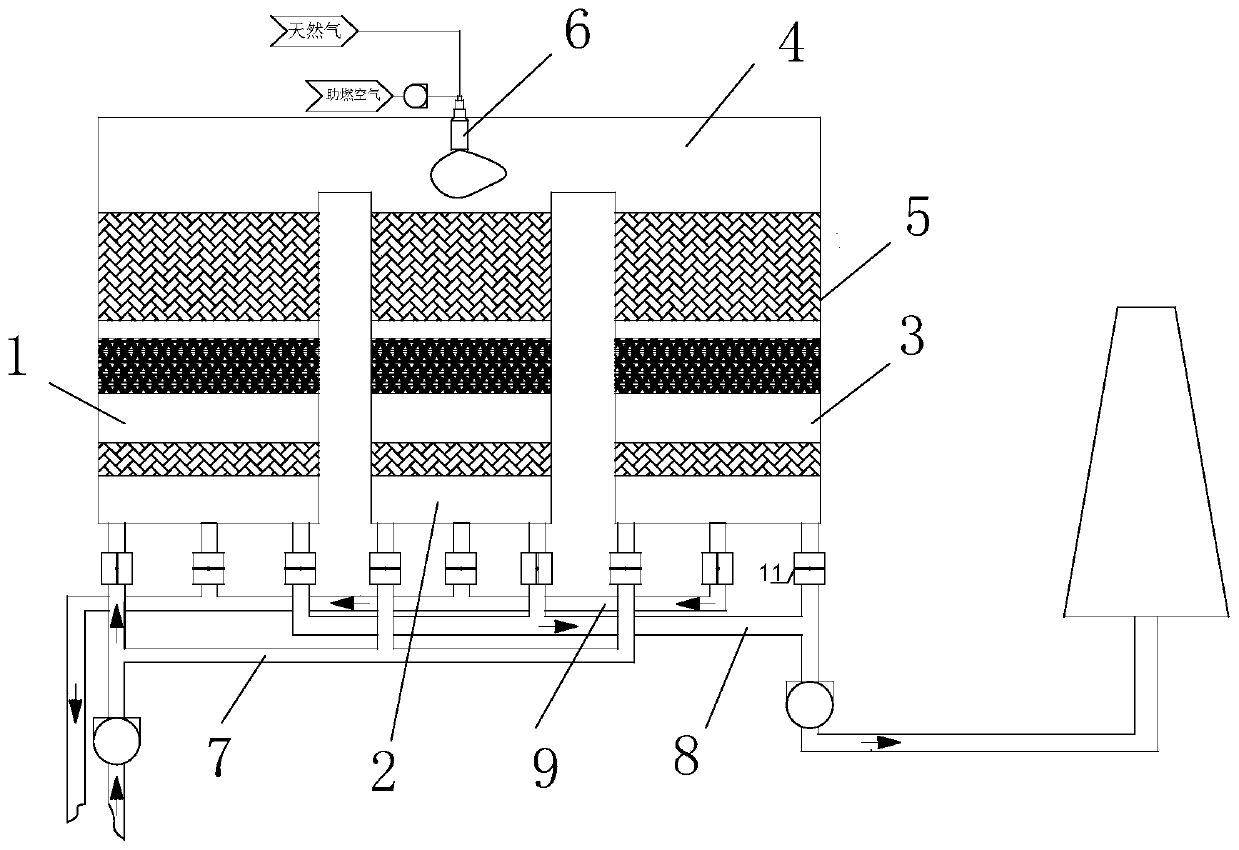

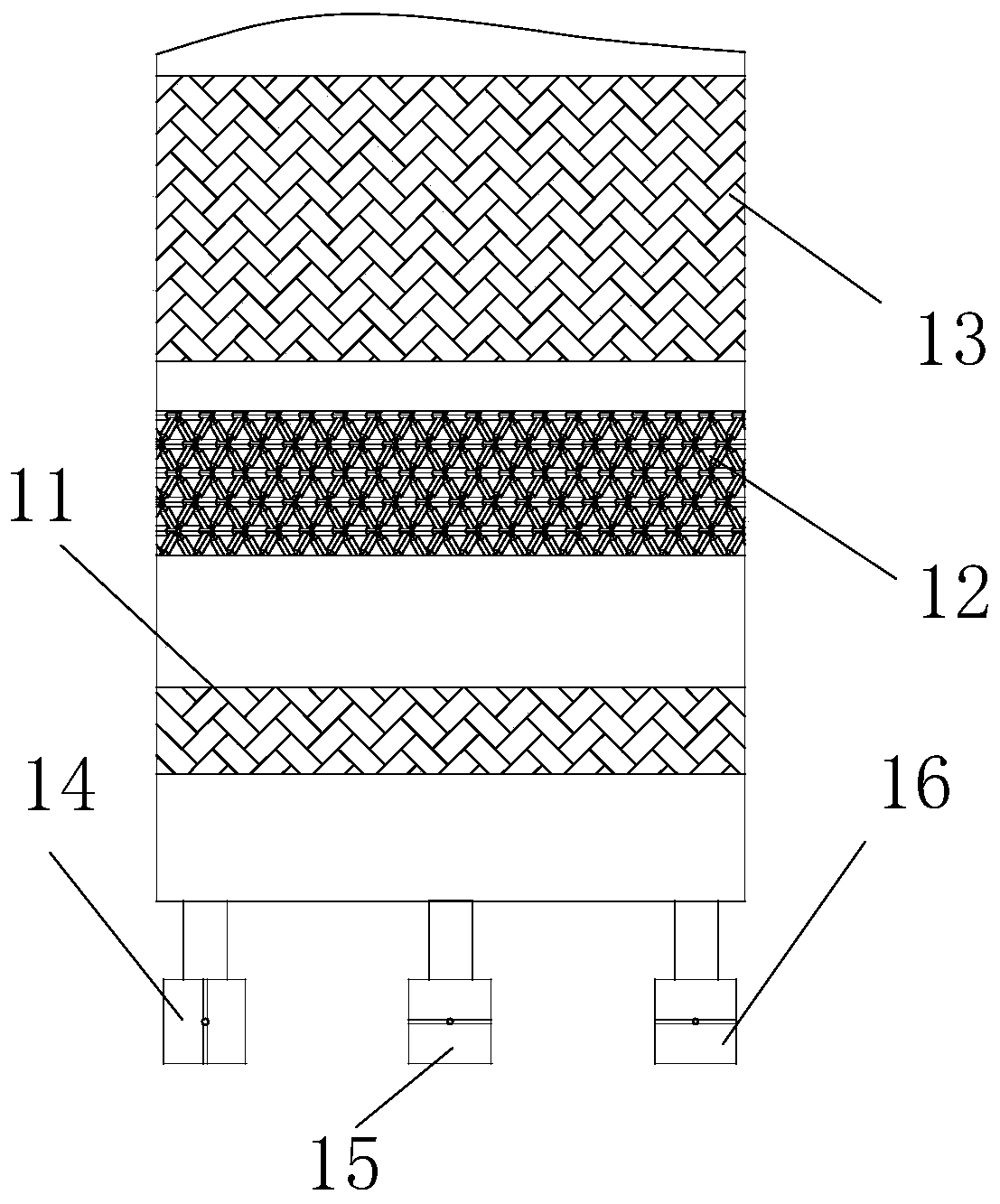

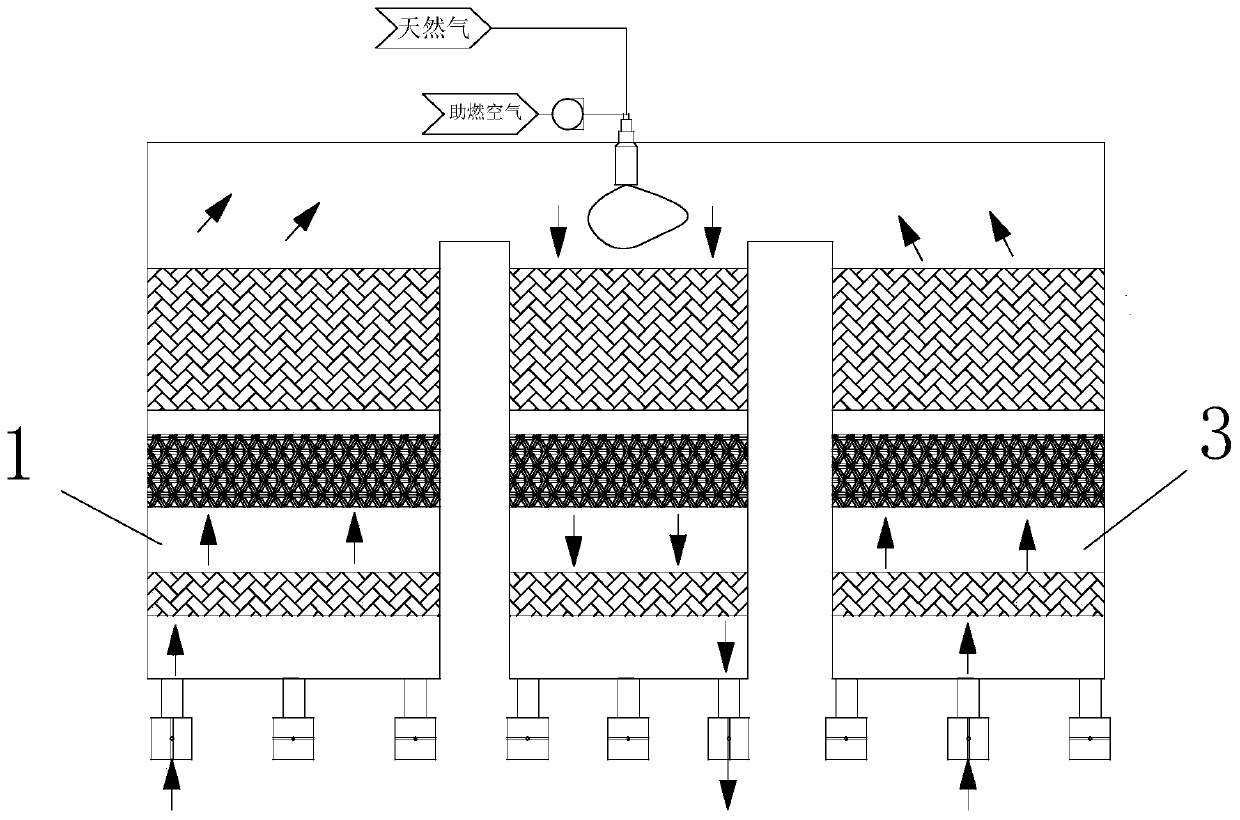

[0041] The present invention will now be further described with reference to specific embodiments. These drawings are all simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0042] like Figures 1 to 5 As shown, a new type of VOCs disposal device based on RTO and RCO working together, including a tower body 5, the tower body 5 is provided with a first tower cavity 1, a second tower cavity 2, a third tower cavity 3 and a combustion cavity 4 , each tower cavity is respectively connected to the combustion cavity 4, and the combustion cavity 4 is provided with a burner 6; an intake valve 14, an air outlet valve 16 and a blowback valve 15 are arranged below each tower cavity.

[0043] The intake valve 14, the outlet valve 16 and the blowback valve 15 are vertical air-to-open switching valves.

[0044] A lower heat storage layer 11 , a catalytic oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com