Air conditioner temperature adjustment-control unit utilizing high-pressure and low-pressure conversion

A high-low-voltage conversion, air-conditioning temperature technology, applied in air-conditioning systems, applications, household appliances, etc., can solve the problems of complex structure of refrigeration operation mechanism, poor environmental protection, high cost, etc., and achieve simple and efficient operation procedures, high safety, and improved The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

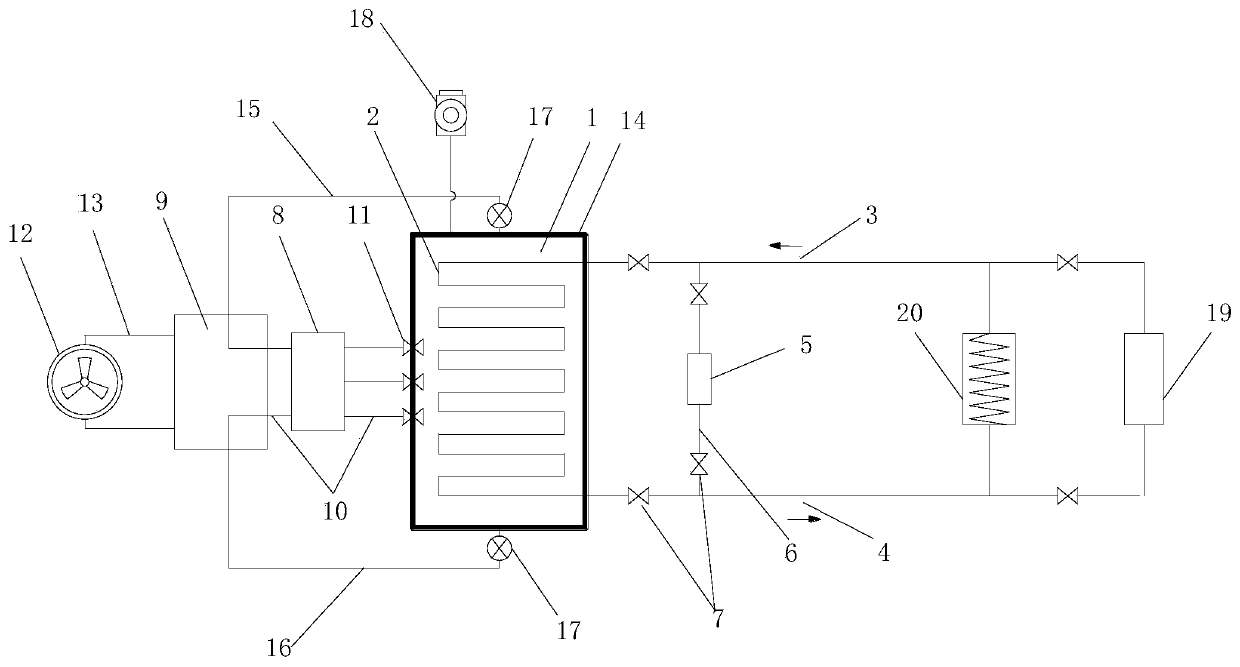

[0026] see figure 1 , an air-conditioning temperature control unit utilizing high and low pressure conversion, comprising a low-pressure barrel 1, a high-pressure barrel 8 and a first heat exchanger 9, the inner cavity of the low-pressure barrel 1 is provided with a refrigerant water pipe 2, and the refrigerant water pipe 2 is installed in a low-pressure The inner cavity of the barrel 1 is bent in an "S" shape to increase the contact area between the refrigerant water pipe 2 and the airflow in the low-pressure barrel 1, and the low-pressure barrel 1 is externally connected with a vacuum pump 18.

[0027] The control unit is equipped with a refrigerant water inlet pipe 3 and a refrigerant water outlet pipe 4, the inlet end of the refrigerant water pipe 2 is connected to the refrigerant water inlet pipe 3, and the outlet end of the refrigerant water pipe 2 is connected to the refrigerant water outlet pipe 4. The high-pressure barrel 8 is arranged on the side of the low-pressure ...

Embodiment 2

[0032] see figure 1 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the outer side of the barrel wall of the low-pressure barrel 1 is provided with an insulating layer 14, and the insulating layer 14 can effectively separate the low-pressure barrel 1 from the external environment, thereby To ensure the vaporization of the refrigerant or refrigeration solution in the low-pressure barrel 1, the heat in the refrigerant water pipe 2 is mainly absorbed to reduce the influence of the external environment, thereby ensuring the cooling effect.

Embodiment 3

[0034] see figure 1 , this embodiment is further optimized as Embodiment 1, on the basis of which, the control unit also includes a cooling pump 12, the first heat exchanger 9 is externally connected to a cooling water pipe 13, and the cooling water pipe 13 is connected to the cooling pump 12 , the first heat exchanger 9, the cooling water pipe 13, and the cooling pump 12 form a circulation loop. During refrigeration operation, the refrigerant or refrigeration solution is input into the first heat exchanger 9 through the water delivery pipe 10, and the first heat exchanger 9 forms a circulation loop through the cooling water pipe 13 and the cooling pump 12 to reduce the temperature of the cooling water. On the one hand, it can improve the cooling effect of the refrigerant or the refrigeration solution, on the other hand, it can accelerate the exothermic liquefaction speed of the refrigerant or the refrigeration solution, and improve the working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com