Memory and forming method thereof

A memory and storage structure technology, which is applied in the manufacturing of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of complex process flow, long cycle and high process cost in the contact part of the wafer, and improve the lateral isolation performance. , the effect of improving quality and reducing the difficulty of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Please refer to Figures 1A to 1D , is a schematic diagram of the formation process of a semiconductor structure.

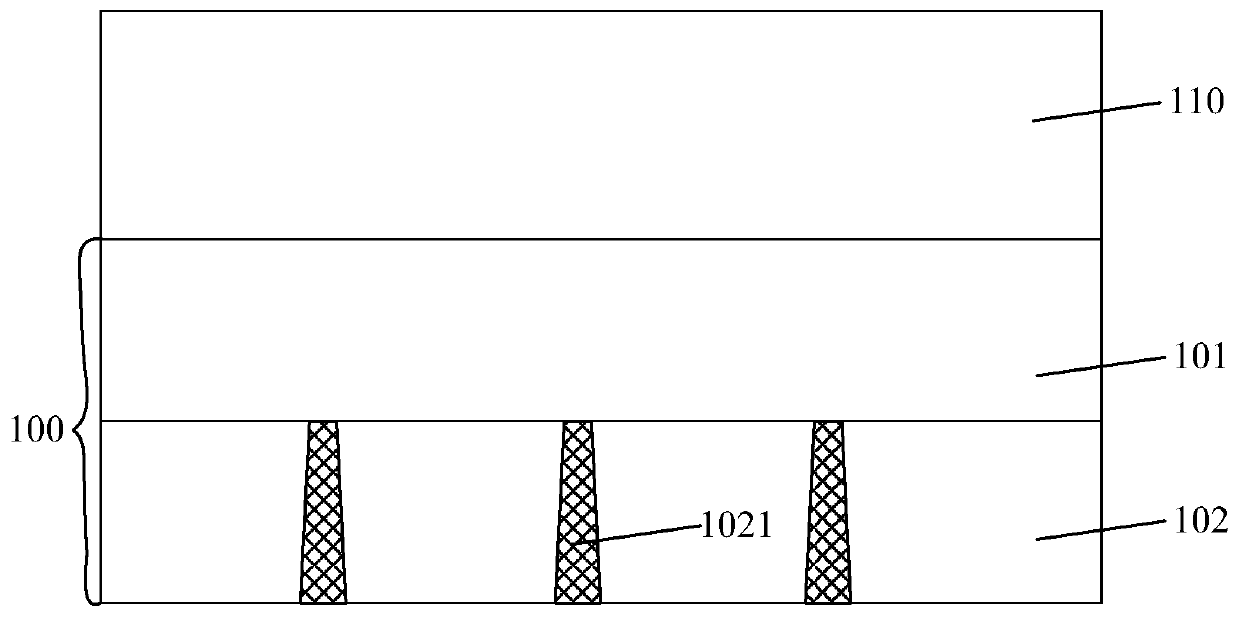

[0029] Please refer to Figure 1A , the base 100 includes a substrate 101 and a device layer 102, the substrate 101 includes two opposite surfaces respectively being the front and the back; the device layer 102 is formed on the front of the substrate 101, and the device layer 102 An interconnection structure 1021 is formed in it; after thinning the back of the substrate 101 , a dielectric layer 110 is formed on the back of the substrate 101 .

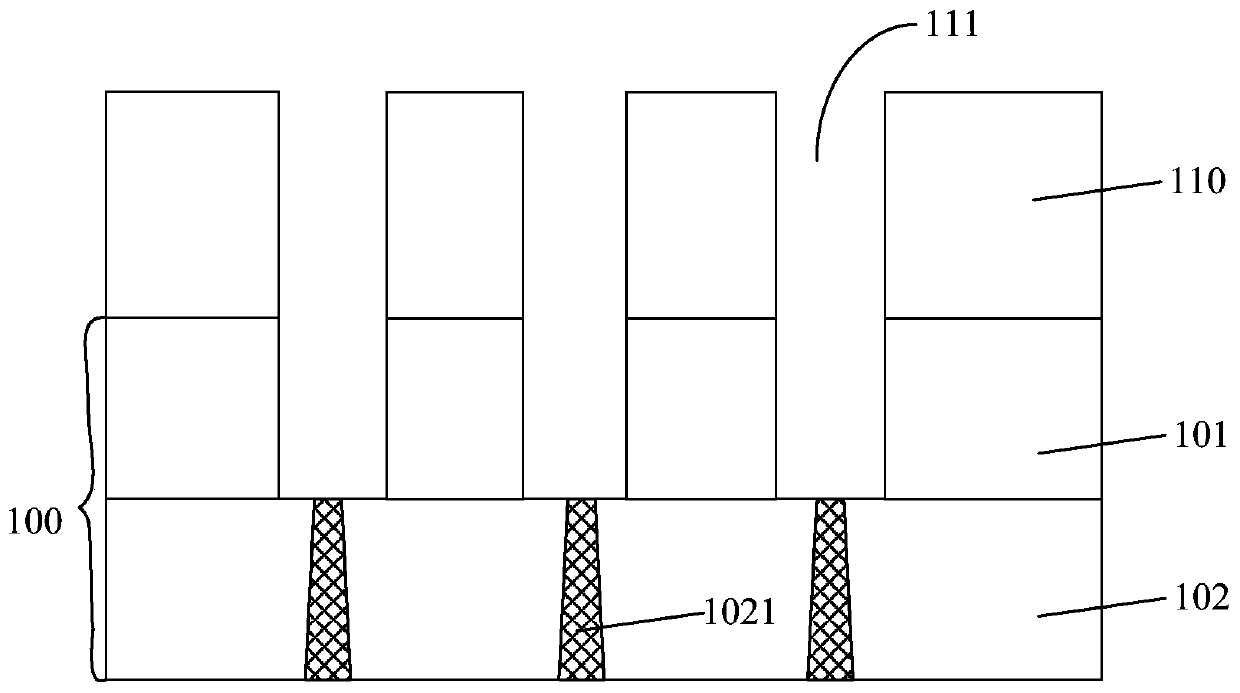

[0030] Please refer to Figure 1B , etching the dielectric layer 110 and the substrate 101 to form a through hole 111 penetrating through the dielectric layer 110 and the substrate 101 , and the interconnection structure 1021 is exposed at the bottom of the through hole 111 .

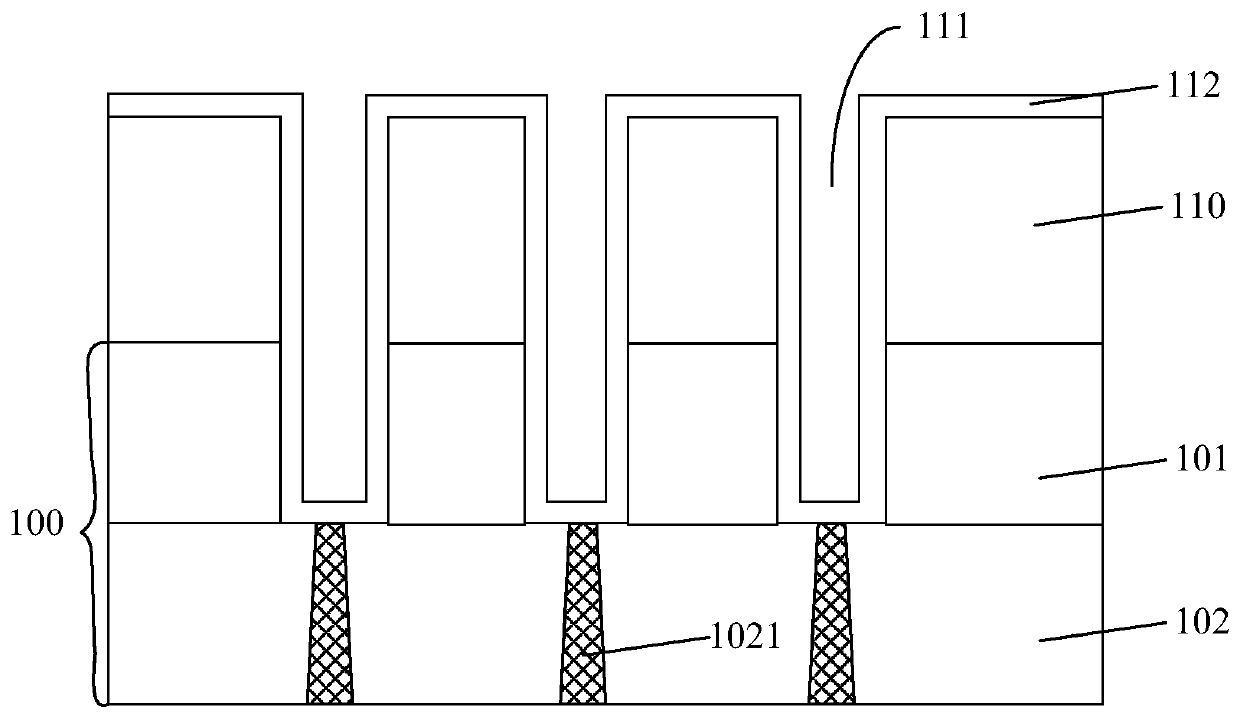

[0031] Please refer to Figure 1C , forming the isolation layer 112 covering the inner wall surface of the through hole 111 .

[0032] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com