Double-sided water-cooling heat dissipation structure of high-power-density IGBT module and processing technology

A high-power density, water-cooled heat dissipation technology, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of uneven heat dissipation of double-sided water-cooling, and achieve excellent lateral rapid thermal conductivity and environmental protection device reliability. , Solve the effect of water cooling uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

[0034] The gist of the present invention is to provide a simple solution to the problem of uneven heat dissipation of double-sided water cooling and improve the reliability of the module.

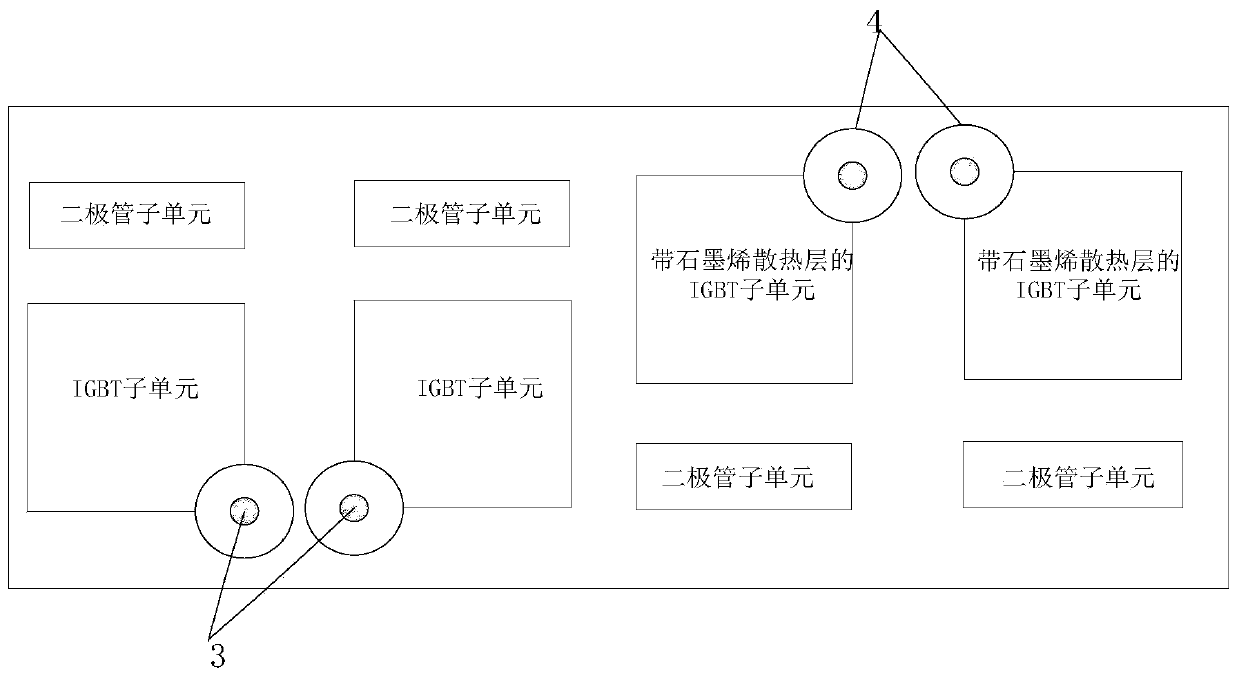

[0035] In the middle of the upper and lower copper-clad ceramic substrates of the present invention, 3-4 IGBT modules can be placed, that is, a module composed of IGBT subunits and diode subunits. A subunit refers to a semiconductor structure made of a chip and its front and back sides. Sum. IGBT sub-units and diode sub-units can be interleaved, which is beneficial to suppress thermal coupling. The upper and lower copper-clad ceramic substrates and their intermediate chip subunits are regarded as a group, and several groups of such structures can be placed in the middle of the upper and lower water-cooled plate radiators (mainly depending on the heat dissipation power of the chip). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com